Mubikorwa byo gukora igice cya kabiri,kuriratekinoroji ninzira ikomeye ikoreshwa mugukuraho neza ibikoresho bidakenewe kuri substrate kugirango bigire imiterere yumuzunguruko. Iyi ngingo izerekana uburyo bubiri bwibanze bwo gutondeka muburyo burambuye - guhuza ubushobozi bwa plasma etching (CCP) hamwe na plasma ihindagurika (ICP), no gucukumbura ibyifuzo byabo mugutegura ibikoresho bitandukanye.

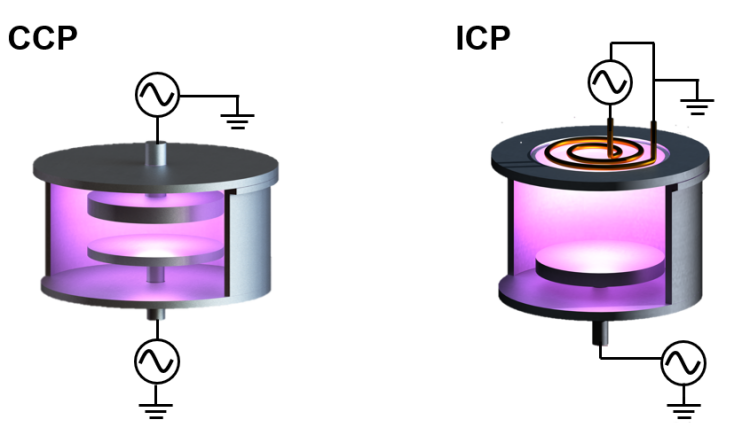

Ubushobozi bwa plasma etching (CCP)

Ubushobozi bwa plasma etching (CCP) bugerwaho mugukoresha voltage ya RF kuri electrode ebyiri zibangikanye binyuze mumateri na capacitori ya DC. Electrode ebyiri na plasma hamwe hamwe bigize capacitor ihwanye. Muri ubu buryo, voltage ya RF ikora capasitifike hafi ya electrode, kandi imbibi zicyatsi zirahinduka hamwe nihindagurika ryihuse rya voltage. Iyo electrone igeze kuriyi shitingi ihinduka vuba, iragaragazwa kandi ikunguka imbaraga, ari nako itera gutandukana cyangwa ionisation ya molekile ya gaze gukora plasma. Ubusanzwe CCP ikoreshwa mubikoresho bifite ingufu zingirakamaro za chimique, nka dielectrics, ariko kubera igipimo cyayo cyo hasi, birakwiriye kubisabwa bisaba kugenzura neza.

Kwishyira hamwe kwa plasma etching (ICP)

Plasma ihujwekurira. Mubikorwa byuyu murima wa magneti, electron mucyumba cya reaction zihuta kandi zikomeza kwihuta mumashanyarazi yatewe, amaherezo zigongana na molekile ya gaze ya reaction, bigatuma molekile zitandukana cyangwa ionize hanyuma zikora plasma. Ubu buryo burashobora gutanga umuvuduko mwinshi wa ionisiyoneri kandi bikemerera ingufu za plasma ningufu za bombardment guhinduka byigenga, bigatumaICPbikwiranye cyane no gutobora ibikoresho bifite ingufu nkeya za chimique, nka silicon nicyuma. Mubyongeyeho, tekinoroji ya ICP nayo itanga uburinganire bwiza nigipimo cyo gutera.

1. Gutera ibyuma

Gukora ibyuma bikoreshwa cyane mugutunganya imiyoboro ihuza imiyoboro myinshi. Mu byo isabwa harimo: igipimo cyo hejuru cyane, guhitamo cyane (kurenza 4: 1 kuri mask ya mask na hejuru ya 20: 1 kuri interineti ya dielectric), guhuza ibice byinshi, kugenzura neza ibipimo, nta kwangiza plasma, kwanduza ibisigara bike, na nta kwangirika kw'icyuma. Ububiko bw'ibyuma busanzwe bukoresha ibikoresho bya plasma bifatanye.

•Gutera Aluminium: Aluminium nigikoresho cyingenzi cyinsinga mugice cyo hagati ninyuma yo gukora chip, hamwe nibyiza byo kwihanganira bike, kubitsa byoroshye no gutobora. Ubusanzwe Aluminium ikoresha plasma ikorwa na gaze ya chloride (nka Cl2). Aluminium ikora hamwe na chlorine kugirango ikore aluminium chloride ihindagurika (AlCl3). Mubyongeyeho, ibindi bice nka SiCl4, BCl3, BBr3, CCl4, CHF3, nibindi birashobora kongerwaho kugirango bikureho oxyde ya okiside hejuru ya aluminiyumu kugirango hamenyekane neza.

• Tungsten etching: Mubice byinshi byububiko bwicyuma cyo guhuza imiyoboro, tungsten nicyuma nyamukuru gikoreshwa mugice cyo hagati cyo guhuza chip. Imyuka ya florine cyangwa chlorine irashobora gukoreshwa mugutobora ibyuma bya tungsten, ariko imyuka ya fluor ifite ubushobozi buke bwo guhitamo okiside ya silicon, mugihe imyuka ya chlorine (nka CCl4) ifite amahitamo meza. Ubusanzwe azote yongerwa kuri gaze ya reaction kugirango ibone uburyo bwo guhitamo kole nyinshi, kandi ogisijeni yongerwaho kugirango igabanye imyuka ya karubone. Gutera tungsten hamwe na gaze ishingiye kuri chlorine irashobora kugera kuri anisotropique no guhitamo cyane. Imyuka ikoreshwa mugukama kwa tungsten ni SF6, Ar na O2, muri zo SF6 irashobora kubora muri plasma kugirango itange atome ya fluor na tungsten kugirango imiti ikore fluoride.

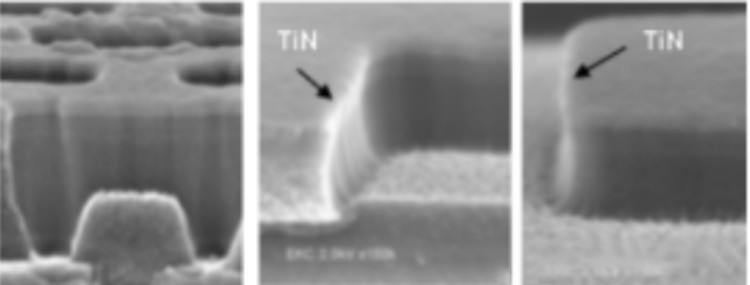

• Nitride ya Titanium: Nitride ya Titanium, nkibikoresho bya mask ikomeye, isimbuza nitride ya silicon gakondo cyangwa maskide ya okiside muburyo bubiri bwa damascene. Gutera nitride ya Titanium ikoreshwa cyane mugikorwa cyo gufungura mask ikomeye, kandi ibicuruzwa nyamukuru ni TiCl4. Guhitamo hagati ya mask gakondo na buke-k dielectric layer ntabwo iri hejuru, bizaganisha kumiterere yumwirondoro wa arc hejuru yumurongo muto wa k dielectric no kwaguka kwubugari bwa groove nyuma yo gutobora. Umwanya uri hagati yumurongo wicyuma wabitswe ni muto cyane, ukunda kuraro cyangwa kumeneka neza.

2. Gutera insulator

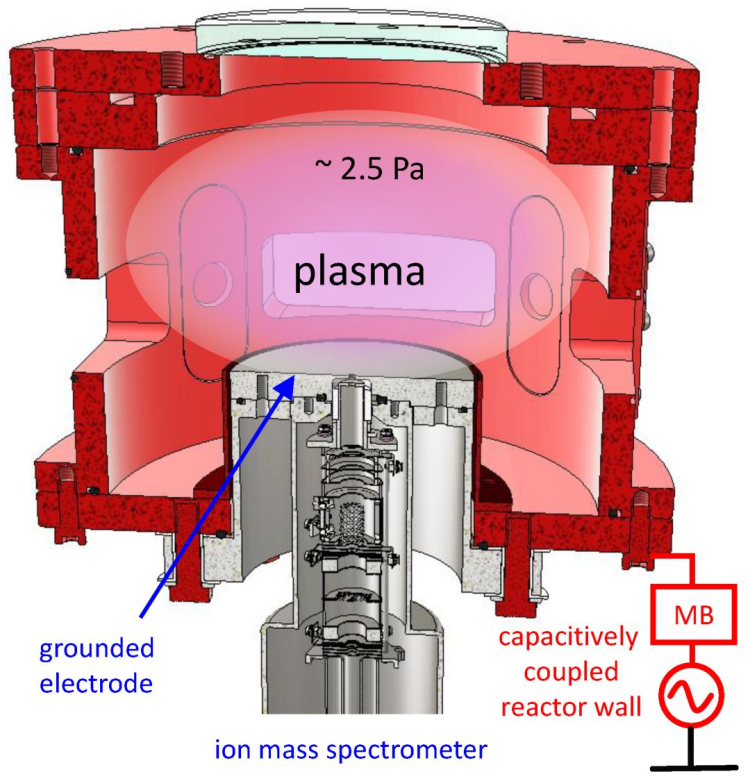

Ikintu cyo gukuramo insulator mubisanzwe ni ibikoresho bya dielectric nka silicon dioxyde cyangwa nitride ya silicon, bikoreshwa cyane mugukora imyobo yo guhuza hamwe nu mwobo kugirango uhuze ibice bitandukanye byumuzunguruko. Kurya dielectric mubisanzwe ikoresha etcher ishingiye kumahame yo guhuza plasma ifatanye.

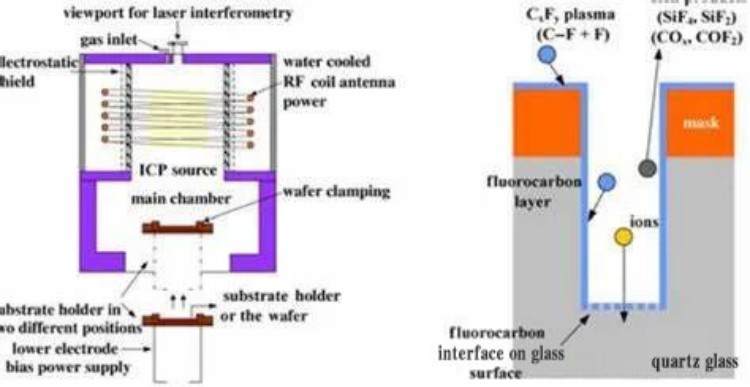

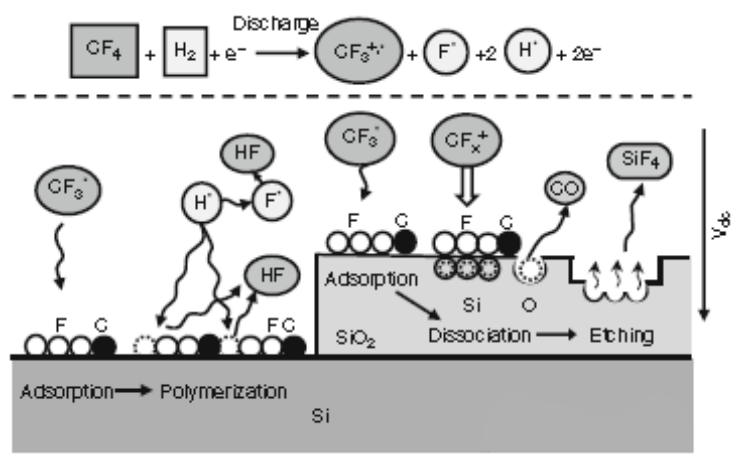

• Plasma yogosha ya firime ya dioxyde de silicon: Filime ya dioxyde de silicon isanzwe iba ikoresheje imyuka ya gaz irimo fluor, nka CF4, CHF3, C2F6, SF6 na C3F8. Carbone iri muri gaze ya gaze irashobora gukora hamwe na ogisijeni murwego rwa oxyde kugirango itange umusaruro wa CO na CO2, bityo ikureho ogisijeni murwego rwa oxyde. CF4 ni gaze ikoreshwa cyane. Iyo CF4 igonganye na electron zifite ingufu nyinshi, hakorwa ion zitandukanye, radicals, atome na radicals yubusa. Fluorine yubusa irashobora gufata imiti hamwe na SiO2 na Si kugirango itange silicon tetrafluoride ihindagurika (SiF4).

• Plasma etching ya silicon nitride ya firime: Filime ya nitride ya silicon irashobora gushirwa hakoreshejwe plasma ikoresheje CF4 cyangwa CF4 ivanze (hamwe na O2, SF6 na NF3). Kuri firime ya Si3N4, mugihe plasma ya CF4-O2 cyangwa plasma ya gaze irimo atome ya F ikoreshwa mugutobora, igipimo cyo gutobora nitride ya silicon gishobora kugera kuri 1200Å / min, kandi guhitamo ibibyimba bishobora kugera kuri 20: 1. Igicuruzwa nyamukuru ni silicon tetrafluoride ihindagurika (SiF4) yoroshye kuyikuramo.

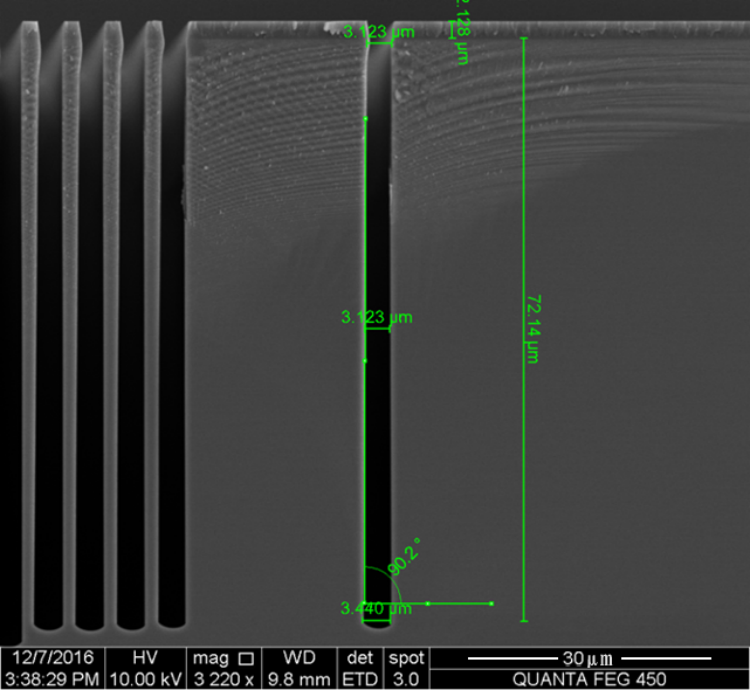

3. Kuringaniza kristu imwe ya silicon

Intungamubiri imwe ya kirisiti ya silicon ikoreshwa cyane mugukora umwobo muto (STI). Ubu buryo busanzwe bukubiyemo inzira yo gutera imbere hamwe nuburyo bukuru bwo gutobora. Inzira igezweho ikoresha gaze ya SiF4 na NF kugirango ikureho oxyde ya oxyde hejuru ya silikoni imwe ya kirisiti ikoresheje ibisasu bikomeye bya ion hamwe nibikorwa bya chimique yibintu bya fluor; ibyingenzi byingenzi bikoresha hydrogen bromide (HBr) nkibisanzwe. Bromine radicals yangirika na HBr mubidukikije bya plasma ikora hamwe na silicon ikora silicon tetrabromide ihindagurika (SiBr4), bityo ikuraho silikoni. Imashini imwe ya kirisiti ya silicon isanzwe ikoresha imashini ifata plasma ihujwe.

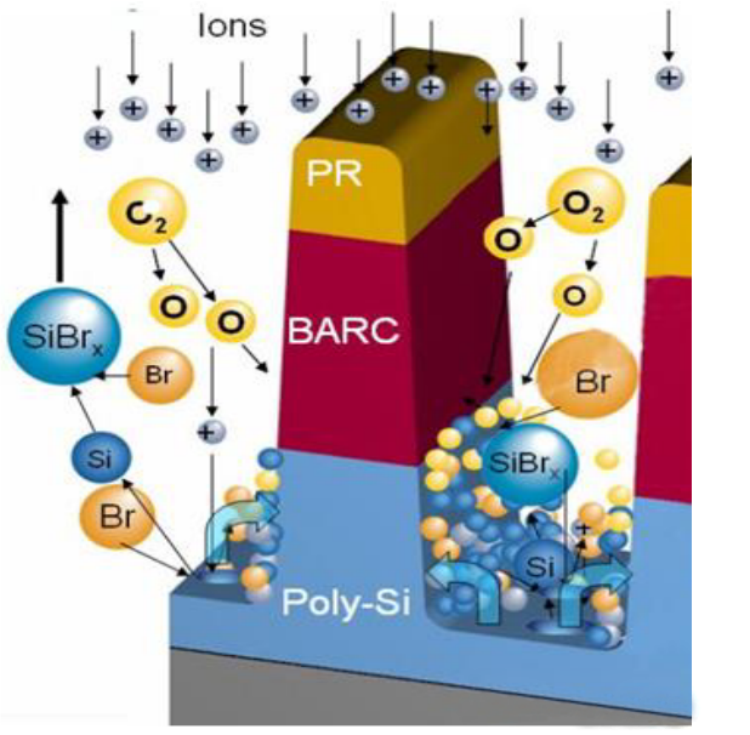

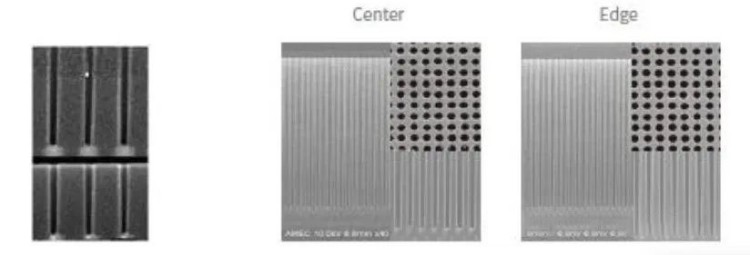

4. Gutera Polysilicon

Gutobora Polysilicon nimwe mubikorwa byingenzi bigena ingano y amarembo ya tristoriste, kandi ingano y irembo igira ingaruka ku mikorere yimikorere ihuriweho. Kurya polysilicon bisaba igipimo cyiza cyo guhitamo. Imyuka ya Halogene nka chlorine (Cl2) isanzwe ikoreshwa kugirango igere kuri anisotropique, kandi ifite igipimo cyiza cyo guhitamo (kugeza 10: 1). Imyuka ya Bromine nka hydrogen bromide (HBr) irashobora kubona igipimo kinini cyo guhitamo (kugeza 100: 1). Uruvange rwa HBr na chlorine na ogisijeni birashobora kongera umuvuduko wo kuribwa. Ibicuruzwa biva muri gaze ya halogene na silicon bishyirwa kumuhanda kugirango bigire uruhare mukurinda. Ubusanzwe polysilicon ikoresha imashini ifata plasma ihujwe.

Byaba bifatanyirijwe hamwe na plasma yogusimba cyangwa guhuza plasma ihindagurika, buriwese afite ibyiza byihariye nibiranga tekiniki. Guhitamo tekinoroji ikwiye ntishobora kuzamura umusaruro gusa, ahubwo inemeza umusaruro wibicuruzwa byanyuma.

Igihe cyo kohereza: Ugushyingo-12-2024