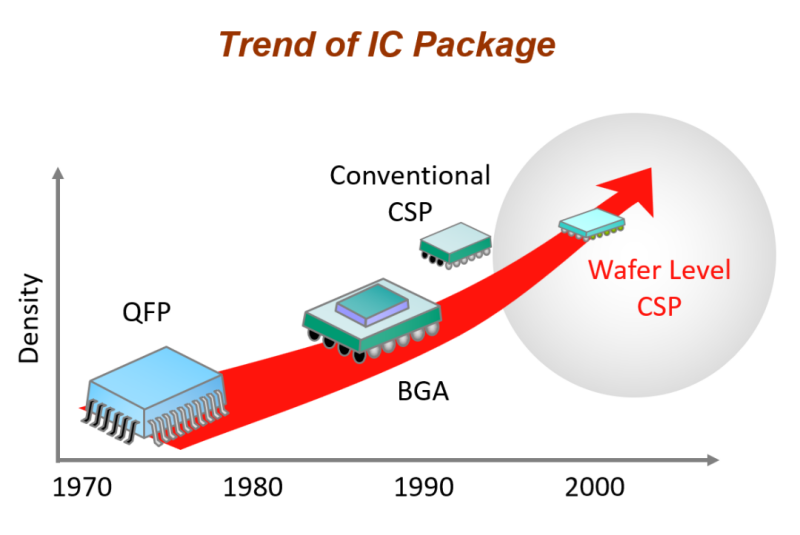

Tekinoroji yo gupakira nimwe mubikorwa byingenzi mubikorwa bya semiconductor. Ukurikije imiterere yipaki, irashobora kugabanywamo pake ya sock, hejuru yububiko bwa paje, BGA pack, pake yubunini bwa chip (CSP), chip module imwe ya chip module (SCM, ikinyuranyo hagati yinsinga kumurongo wacapwe (PCB) hamwe nu muzunguruko wuzuzanya (IC) ikibaho cya padiri), paketi nyinshi ya chip module (MCM, ishobora guhuza chipi itandukanye), urwego rwa wafer (WLP, harimo nabafana ba wafer urwego (FOWLP), ibice byububiko bwa micye .

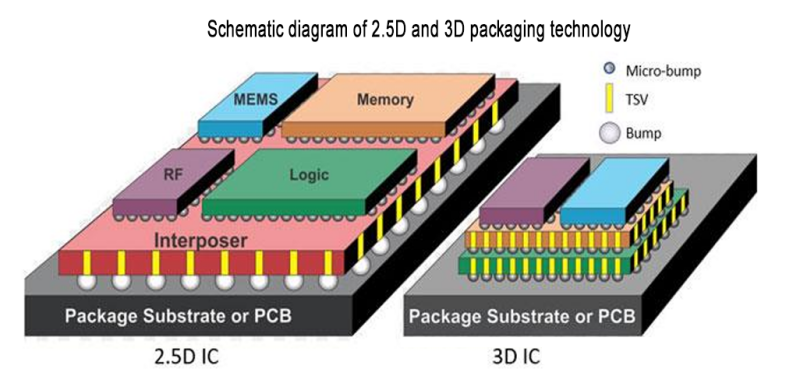

Imiterere yo gupakira 3D igabanijwemo cyane mubyiciro bitatu: ubwoko bwashyinguwe (gushyingura igikoresho mumashanyarazi menshi cyangwa gushyingurwa muri substrate), ubwoko bwimikorere ya substrate (guhuza silicon wafer: banza uhuze ibice hamwe na wafer substrate kugirango ikore substrate ikora hanyuma hanyuma utegure imirongo myinshi ihuza imirongo, hanyuma ukusanyirize hamwe izindi chip cyangwa ibice kumurongo wo hejuru) hamwe nubwoko butondekanye (wafer ya silicon yashizwemo na wafer ya silicon, chip zometse kuri wafer ya silicon, na; imitwe ikomatanyirijwe hamwe).

Uburyo bwa 3D bwo guhuza burimo guhuza insinga (WB), flip chip (FC), binyuze muri silicon ukoresheje (TSV), umuyobozi wa firime, nibindi.

TSV itahura guhuza vertical hagati ya chip. Kubera ko umurongo uhuza umurongo ufite intera ngufi n'imbaraga ndende, biroroshye kumenya miniaturizasiya, ubucucike bukabije, imikorere myinshi, hamwe nuburyo butandukanye bwo gupakira ibintu. Mugihe kimwe, irashobora kandi guhuza chip yibikoresho bitandukanye;

kuri ubu, hari ubwoko bubiri bwa tekinoroji yo gukora mikorobe ikoresheje inzira ya TSV: gupakira ibice bitatu byumuzunguruko (3D IC guhuza) hamwe nububiko bwa silikoni-eshatu (3D Si guhuza).

Itandukaniro riri hagati yuburyo bubiri nuko:

. -Guhuza).

.

. nta tandukaniro riri hagati ya chipi ihujwe nuburyo bwo gupakira bwa silikoni ya 3D, kandi gukoresha ingufu, ingano, nuburemere bwa chip ni bito, kandi amashanyarazi ni meza.

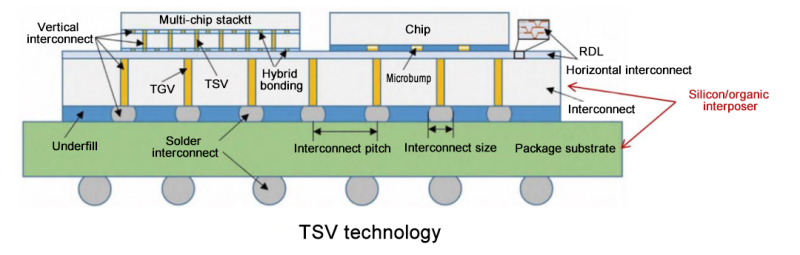

Inzira ya TSV irashobora kubaka inzira yerekana ibimenyetso bihagaritse binyuze muri substrate hanyuma igahuza RDL hejuru no hepfo ya substrate kugirango ikore inzira-yimiyoboro itatu. Kubwibyo, inzira ya TSV nimwe mumabuye yingenzi yo kubaka ibikoresho-bitatu bya passiyo yububiko.

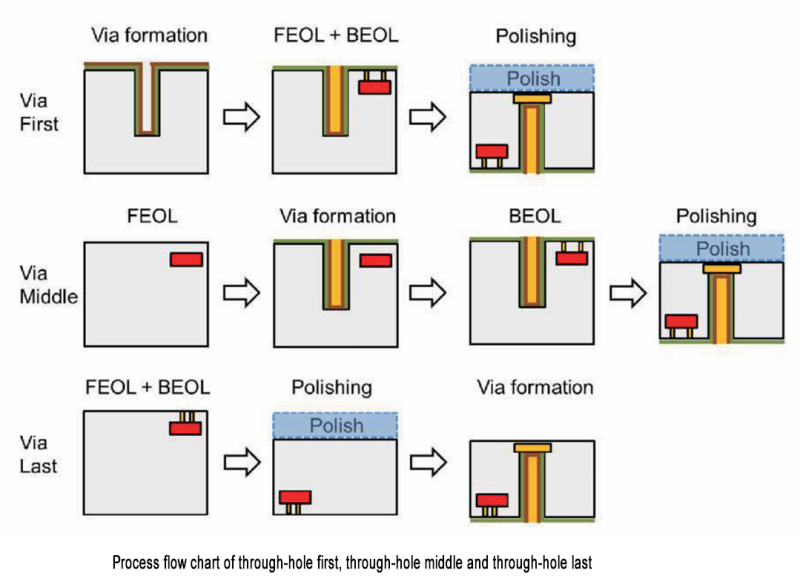

Ukurikije gahunda iri hagati yumurongo wimbere wumurongo (FEOL) numurongo winyuma wumurongo (BEOL), inzira ya TSV irashobora kugabanwa mubikorwa bitatu byingenzi byinganda, aribyo, binyuze muri mbere (ViaFirst), binyuze hagati (Via Hagati) na ukoresheje inzira yanyuma (Via Iheruka), nkuko bigaragara ku gishushanyo.

1. Binyuze mubikorwa

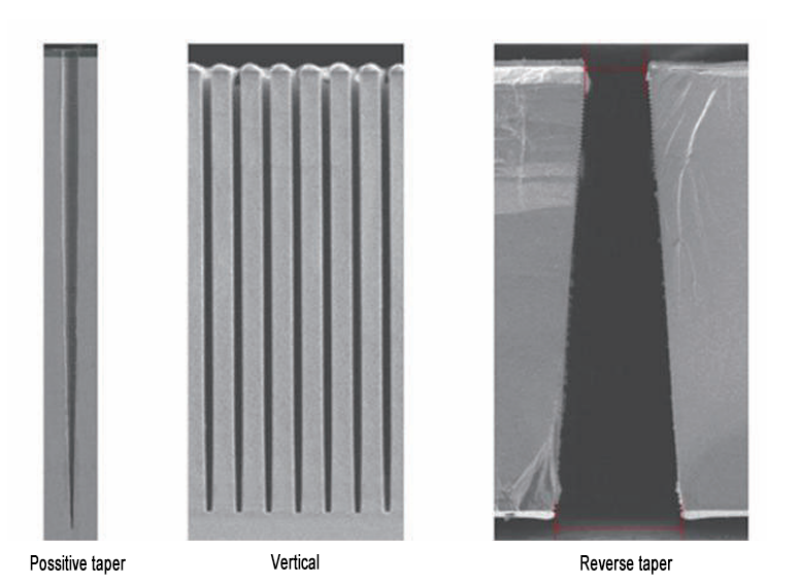

Binyuze muri etching inzira nurufunguzo rwo gukora imiterere ya TSV. Guhitamo uburyo bukwiye bwo gutobora birashobora kunoza neza imbaraga za mashini hamwe namashanyarazi ya TSV, kandi bifitanye isano no kwizerwa muri rusange kubikoresho bya TSV-bitatu.

Kugeza ubu, hari ibintu bine byingenzi byingenzi TSV ikoresheje uburyo bwo gutobora: Byimbitse cyane Ion Etching (DRIE), gutobora amazi, gufotora bifashishije amashanyarazi (PAECE) no gucukura laser.

.

Kwiyunvikana kwimbitse ion, bizwi kandi nka DRIE inzira, nuburyo bukoreshwa cyane muri TSV yogukoresha, bukoreshwa cyane cyane kugirango tumenye TSV binyuze mumiterere ifite igipimo kinini. Inzira ya plasma isanzwe irashobora kugera gusa kuri ubujyakuzimu bwa microne nyinshi, hamwe nigipimo gito cyo kubura no kubura guhitamo mask. Bosch yakoze iterambere rijyanye niyi shingiro. Ukoresheje SF6 nka gaze ikora kandi ikarekura gaze ya C4F8 mugihe cyo guterana nkikingira rya passiwasi kuruhande, inzira ya DRIE yatunganijwe irakwiriye gushira ibice byinshi. Kubwibyo, byitwa kandi inzira ya Bosch nyuma yuwayihimbye.

Igishushanyo gikurikira ni ifoto yikigereranyo kinini cyakozwe hakoreshejwe uburyo bwo KUNYAZA.

Nubwo inzira ya DRIE ikoreshwa cyane mubikorwa bya TSV bitewe nuburyo bwiza bwo kugenzura, ibibi byayo ni uko uburinganire bwinzira nyabagendwa bukennye kandi hashyizweho inenge zuzuye iminkanyari. Iyi nenge irakomeye cyane mugihe cyo guhuza ibice byinshi.

(2) Kurya neza

Gutose bitose bikoresha uruvange rwa mask hamwe nubushakashatsi bwimiti kugirango bive mu mwobo. Igisubizo gikunze gukoreshwa cyane ni KOH, ishobora gutera imyanya kuri substrate ya silicon idakingiwe na mask, bityo igakora ibyifuzo byanyuze mu mwobo. Gutose bitose nuburyo bwambere binyuze mu mwobo wo gutobora byateye imbere. Kubera ko inzira zayo n'ibikoresho bisabwa byoroshye, birakwiriye kubyara umusaruro wa TSV ku giciro gito. Nyamara, uburyo bwacyo bwo gutondeka imiti bugena ko umwobo wakozwe nubu buryo uzagira ingaruka ku cyerekezo cya kristu cyerekezo cya silicon wafer, bigatuma ibice byanyuze mu mwobo bidahagaritse ariko bikerekana ibintu bigaragara byerekana ubugari hejuru no hepfo. Iyi nenge igabanya ikoreshwa rya etching itose mubikorwa bya TSV.

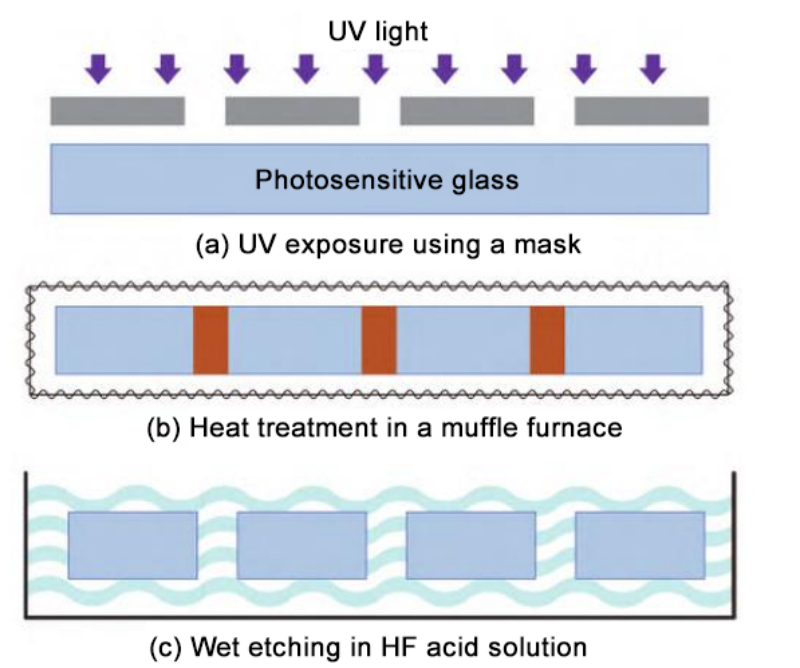

(3) Ifoto ifashwa na electrochemical etching (PAECE)

Ihame shingiro ryamafoto afashwa na electrochemical etching (PAECE) nugukoresha urumuri ultraviolet kugirango wihutishe kubyara ibice bibiri bya elegitoronike, bityo byihutishe inzira yo guterwa amashanyarazi. Ugereranije nuburyo bukoreshwa cyane na DRIE, inzira ya PAECE irakwiriye cyane mugushushanya ultra-nini ya aspect igereranijwe binyuze mu mwobo urenga 100: 1, ariko ibibi byayo ni uko kugenzura ubujyakuzimu bworoshye ari intege nke kurusha DRIE, kandi ikoranabuhanga ryarwo rishobora bisaba ubundi bushakashatsi no kunoza imikorere.

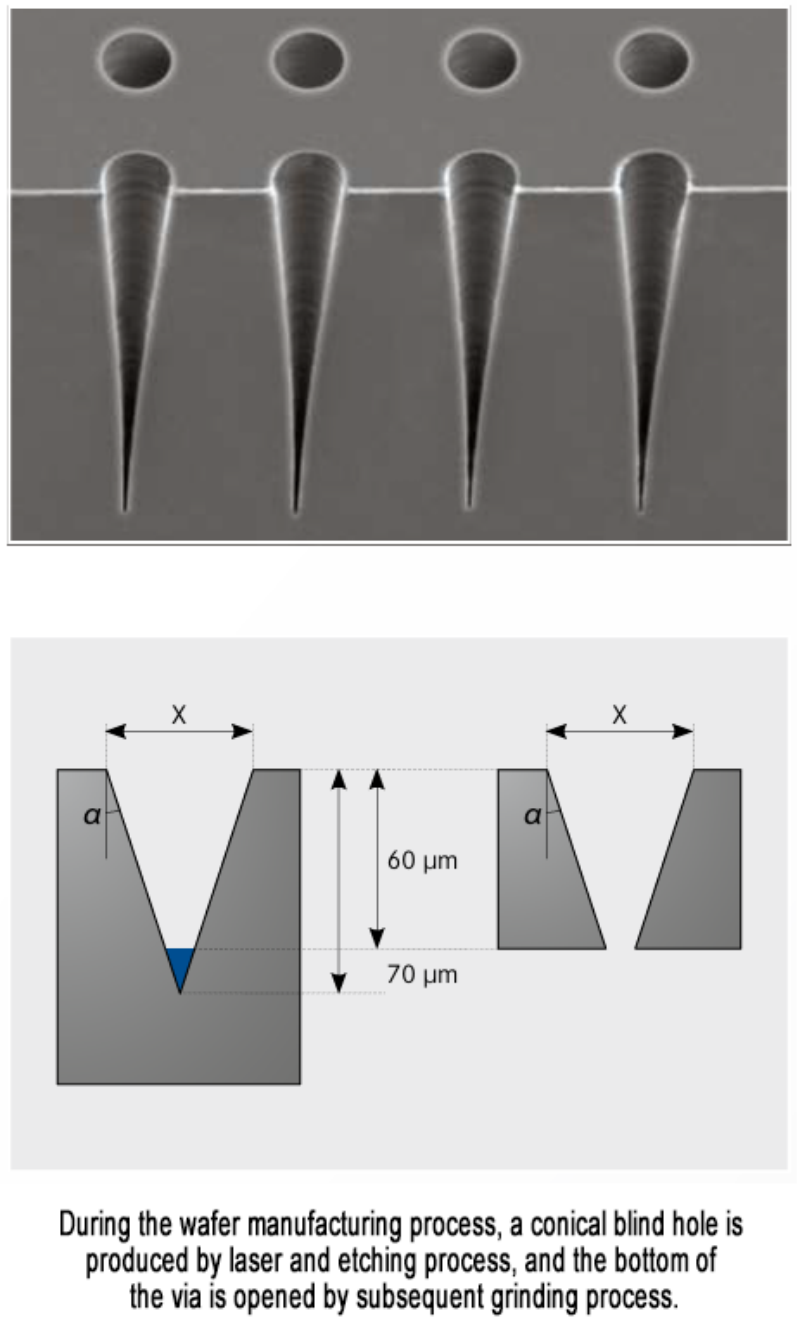

(4) Gucukura

Iratandukanye nuburyo butatu buvuzwe haruguru. Uburyo bwo gucukura laser nuburyo bwumubiri gusa. Ikoresha cyane cyane imirasire yingufu za lazeri kugirango ishonge kandi ihumeke ibikoresho bya substrate mugace kerekanwe kugirango tumenye muburyo bwubaka inyubako ya TSV.

Umuyoboro unyuze mu gucukura lazeri ufite igipimo kinini kandi umuhanda uhagaze neza. Ariko, kubera ko gucukura lazeri ikoresha ubushyuhe bwaho kugirango ikore umwobo, urukuta rw'umwobo wa TSV ruzagira ingaruka mbi ku kwangirika k'ubushyuhe kandi bigabanye kwizerwa.

2. Inzira yo kubitsa kumurongo

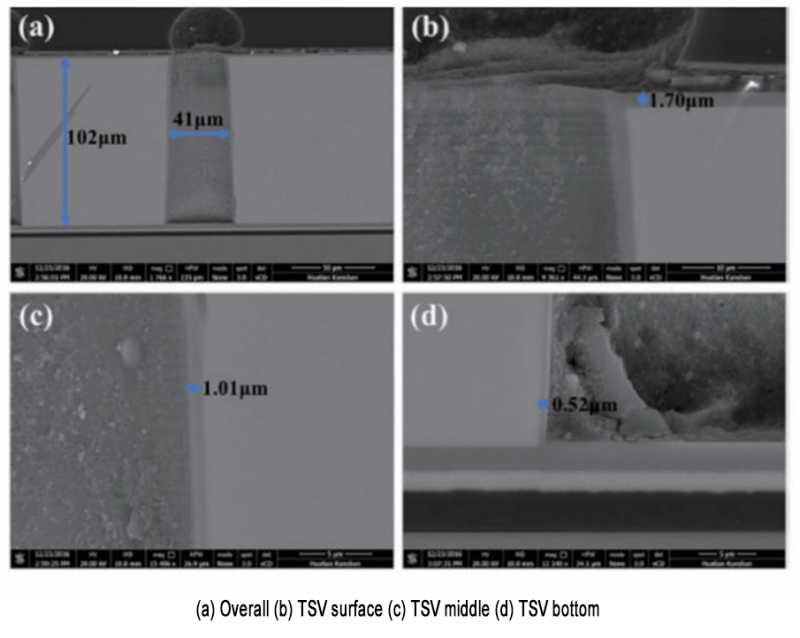

Ubundi buhanga bwingenzi bwo gukora TSV nuburyo bwo kubitsa.

Inzira yo kubitsa ikorwa nyuma yo guca mu mwobo. Ububiko bwabitswe bwabitswe muri rusange ni oxyde nka SiO2. Igice cya liner giherereye hagati yuyobora imbere ya TSV na substrate, kandi kigira uruhare runini mu gutandukanya DC yamenetse. Usibye kubitsa oxyde, barrière hamwe nimbuto zimbuto zirakenewe kugirango umuyobozi wuzuze inzira ikurikira.

Ibikoresho byakozwe bigomba kuba byujuje ibyangombwa bibiri bikurikira:

.

(2) ibice byabitswe birahuye cyane kandi bifatanye neza.

Igishushanyo gikurikira cyerekana ifoto yumurongo wabitswe na plasma yazamuye imyuka ya chimique (PECVD).

Uburyo bwo kubitsa bugomba guhinduka bikurikije inzira zitandukanye za TSV. Kuburyo bwimbere binyuze mu mwobo, uburyo bwo kubika ubushyuhe bwo hejuru burashobora gukoreshwa mugutezimbere ubwiza bwurwego rwa oxyde.

Ubusanzwe ubushyuhe bwo hejuru burashobora gushingira kuri tetraethyl orthosilicate (TEOS) ihujwe nuburyo bwo gukwirakwiza ubushyuhe bwumuriro kugirango habeho urwego rwohejuru rwiza rwa SiO2. Hagati yo gucamo no gusubira mu mwobo, kuva inzira ya BEOL yarangiye mugihe cyo kubitsa, harasabwa uburyo bwo hasi yubushyuhe kugirango habeho guhuza nibikoresho bya BEOL.

Muri ubu buryo, ubushyuhe bwo kubitsa bugomba kugarukira kuri 450 °, harimo no gukoresha PECVD kugirango ubike SiO2 cyangwa SiNx nk'urwego rukingira.

Ubundi buryo busanzwe ni ugukoresha atomic layer deposition (ALD) kugirango ubike Al2O3 kugirango ubone urwego rukomeye.

3. Uburyo bwo kuzuza ibyuma

Inzira yo kuzuza TSV ikorwa ako kanya nyuma yuburyo bwo kohereza liner, nubundi buhanga bwingenzi bugena ubwiza bwa TSV.

Ibikoresho bishobora kuzuzwa birimo dopies polysilicon, tungsten, carbone nanotube, nibindi bitewe nuburyo bwakoreshejwe, ariko inzira nyamukuru iracyari umuringa w'amashanyarazi, kuko inzira yacyo irakuze kandi amashanyarazi n'amashanyarazi birasa cyane.

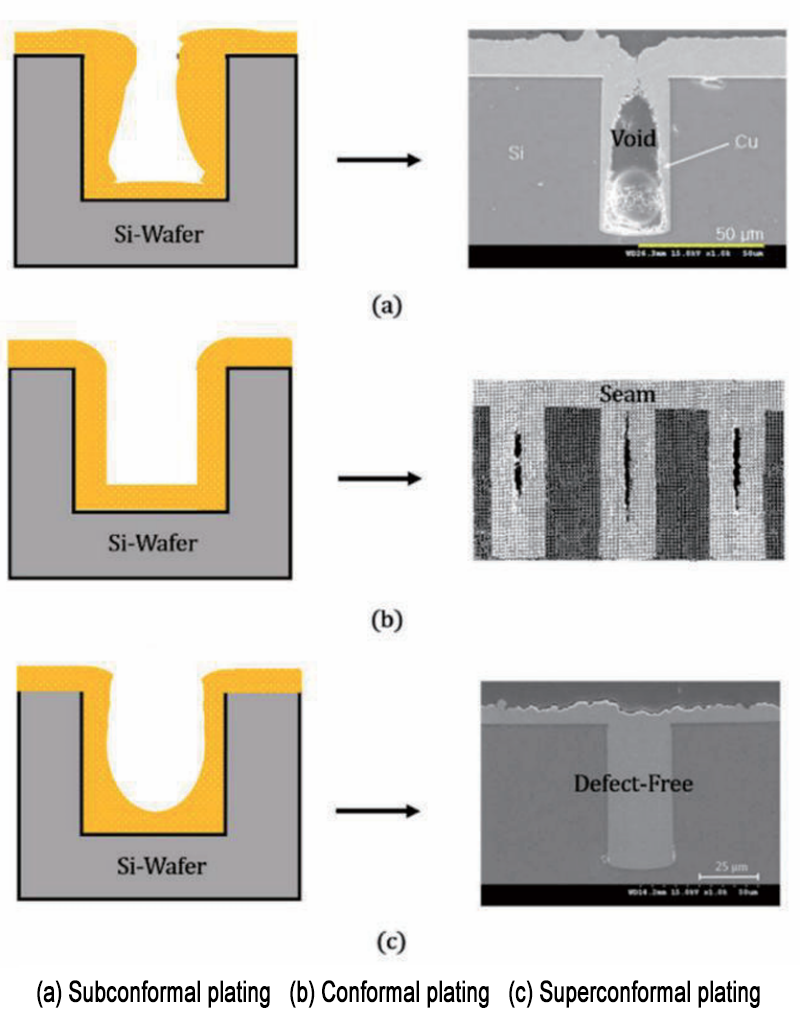

Ukurikije itandukaniro ryo gukwirakwiza igipimo cyayo cya electroplating mu mwobo, irashobora kugabanywa cyane muburyo budasanzwe, buhuza, superconformal na epfo na ruguru amashanyarazi, nkuko bigaragara ku gishushanyo.

Subconformal electroplating yakoreshejwe cyane cyane mugihe cyambere cyubushakashatsi bwa TSV. Nkuko bigaragara ku gishushanyo (a), Cu ion zitangwa na electrolysis zegeranijwe hejuru, mugihe hepfo zuzuye zidahagije, ibyo bigatuma igipimo cya electroplating hejuru yumwobo kiba hejuru kurenza iyo hejuru. Kubwibyo, hejuru yu mwobo uzafungwa mbere yuko yuzura burundu, kandi imbere hazaba icyuho kinini.

Igishushanyo mbonera nifoto yuburyo bwa electroplating uburyo bwerekanwe mubishusho (b). Mugukora ibishoboka byose kugirango hongerwe Cu ion, igipimo cya electroplating kuri buri mwanya uri mu mwobo usanga ari kimwe, bityo rero hazasigara ikidodo gusa imbere, kandi ingano yubusa ni nto cyane ugereranije nuburyo bwa electroplating electroplating, so, ikoreshwa cyane.

Kugirango turusheho kugera ku ngaruka zuzuye zituzuye, uburyo bwa superconformal electroplating uburyo bwasabwe kunoza uburyo bwo guhuza amashanyarazi. Nkuko bigaragara ku gishushanyo (c), mugucunga itangwa rya Cu ion, igipimo cyo kuzuza hepfo kiri hejuru gato ugereranije nizindi myanya, bityo ugahindura intambwe yintambwe yikigereranyo cyo kuzuza uhereye hasi ukageza hejuru kugirango ukureho burundu icyerekezo gisigaye nuburyo bukoreshwa na electroplating method, kugirango ugere kubintu byuzuye bidafite umuringa wuzuye.

Uburyo bwo hasi-hejuru amashanyarazi arashobora gufatwa nkurubanza rwihariye rwuburyo buhebuje. Muri iki gihe, igipimo cya electroplating usibye hepfo cyahagaritswe kuri zeru, kandi amashanyarazi gusa akorwa buhoro buhoro kuva hasi kugeza hejuru. Usibye inyungu zidafite ubusa zuburyo bwa electroplating method, ubu buryo burashobora kandi kugabanya neza igihe rusange cyamashanyarazi, bityo kikaba cyarigishijwe cyane mumyaka yashize.

4. Ikoranabuhanga rya RDL

Inzira ya RDL nubuhanga bwibanze budasanzwe muburyo bwo gupakira ibintu bitatu. Binyuze muriyi nzira, guhuza ibyuma birashobora gukorwa kumpande zombi za substrate kugirango ugere ku ntego yo kugabana ibyambu cyangwa guhuza imiyoboro. Kubwibyo, inzira ya RDL ikoreshwa cyane muri sisitemu yo gupakira abafana-hanze cyangwa 2.5D / 3D.

Muburyo bwo kubaka ibikoresho-bitatu, inzira ya RDL isanzwe ikoreshwa muguhuza TSV kugirango tumenye ibikoresho bitandukanye-bitatu byububiko.

Hano hari inzira ebyiri nyamukuru nyamukuru ya RDL. Iya mbere ishingiye kuri polymers yifotora kandi ihujwe na electroplating yumuringa hamwe nuburyo bwo gutobora; ikindi gishyirwa mubikorwa ukoresheje Cu Damasiko ihujwe na PECVD hamwe na chimique yamashanyarazi (CMP).

Ibikurikira bizamenyekanisha inzira nyamukuru yinzira zombi za RDL.

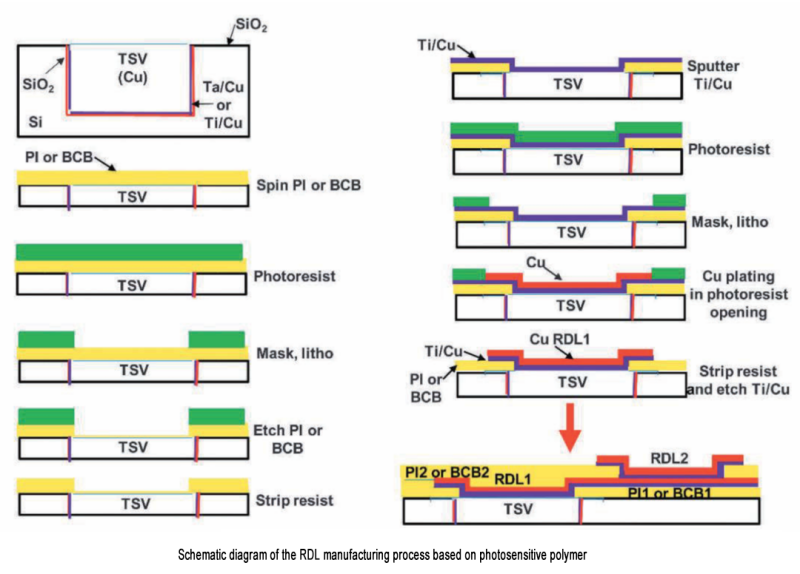

Inzira ya RDL ishingiye kuri polymer yifotora irerekanwa mumashusho hejuru.

Ubwa mbere, urwego rwa PI cyangwa BCB rushyizwe hejuru hejuru ya wafer mukuzunguruka, hanyuma nyuma yo gushyushya no gukira, inzira ya fotolitografiya ikoreshwa mugukingura ibyobo kumwanya wifuzaga, hanyuma bigakorwa. Ibikurikira, nyuma yo gukuraho abafotora, Ti na Cu basutswe kuri wafer binyuze muburyo bwo kubika imyuka yumubiri (PVD) nkurwego rwa bariyeri hamwe nimbuto yimbuto. Ibikurikira, igice cya mbere cya RDL gikorerwa kumurongo wa Ti / Cu ugaragara muguhuza Photolithography hamwe na electroplating Cu inzira, hanyuma fotoreziste ikurwaho hanyuma Ti na Cu birenze bikarekurwa. Subiramo intambwe yavuzwe haruguru kugirango ugire imiterere myinshi ya RDL. Ubu buryo bukoreshwa cyane mu nganda.

Ubundi buryo bwo gukora RDL bushingiye cyane cyane kubikorwa bya Cu Damasiko, bihuza inzira ya PECVD na CMP.

Itandukaniro riri hagati yubu buryo nuburyo bwa RDL bushingiye kuri polymer yifotora ni uko mu ntambwe yambere yo gukora buri cyiciro, PECVD ikoreshwa mu kubitsa SiO2 cyangwa Si3N4 nkigice cyiziritse, hanyuma hagakorwa idirishya kumurongo wikingira ukoresheje fotolitografiya na reaction ya ion reaction, na Ti / Cu barrière / urwego rwimbuto hamwe nu muringa wa kiyobora bisunikwa uko bikurikirana, hanyuma igipimo cyuyobora kikaba cyoroshye kugeza mubyimbye bisabwa na CMP, ni ukuvuga, a urwego rwa RDL cyangwa unyuze mu mwobo.

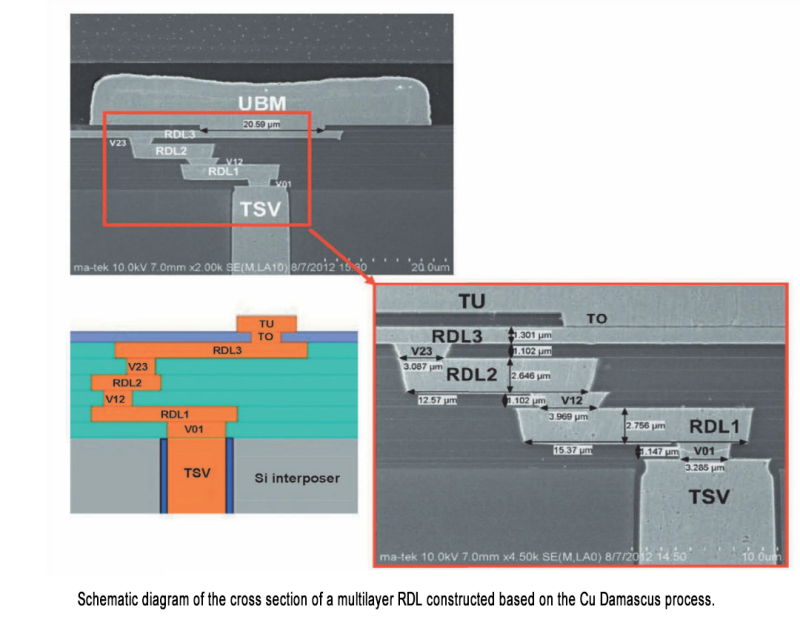

Igishushanyo gikurikira nigishushanyo mbonera nifoto yumusaraba wambukiranya ibice byinshi RDL yubatswe ishingiye kubikorwa bya Cu Damasiko. Birashobora kugaragara ko TSV yabanje guhuzwa nu mwobo wa V01 unyuze mu mwobo, hanyuma igashyirwa hasi kuva hejuru kugeza kuri gahunda ya RDL1, unyuze mu mwobo V12, na RDL2.

Buri cyiciro cya RDL cyangwa cyanyuze mu mwobo gikozwe muburyo bukurikije uburyo bwavuzwe haruguru.Kubera ko inzira ya RDL isaba gukoresha inzira ya CMP, igiciro cyayo cyo gukora kiri hejuru yicyakozwe na RDL ishingiye kuri polymer yifotora, bityo ikoreshwa ryayo ni rito.

5. Ikoranabuhanga rya IPD

Kubikorwa byo gukora ibikoresho-bitatu, usibye kwerekeza kuri chip guhuza MMIC, inzira ya IPD itanga indi nzira yubuhanga bworoshye.

Ibikoresho byinjizwamo passiyo, bizwi kandi nka IPD inzira, bihuza icyaricyo cyose cyibikoresho bya pasiporo harimo inductors ya chip, capacator, résistants, balun ihindura, nibindi kuri substrate itandukanye kugirango ikore isomero ryibikoresho bya pasiporo muburyo bwikibaho gishobora kwimurwa guhamagarwa byoroshye ukurikije ibisabwa.

Kubera ko muri gahunda ya IPD, ibikoresho bya pasiporo bikozwe kandi bigahuzwa muburyo bwo kwimura, inzira yacyo iroroshye kandi ihenze kuruta kuri chip ihuza IC, kandi irashobora gukorerwa cyane nkisomero ryibikoresho byoroshye.

Kubikorwa bya TSV bitatu-bipima ibikoresho bya pasiporo, IPD irashobora kugabanya neza umutwaro wikiguzi cyibikorwa bitatu byo gupakira harimo TSV na RDL.

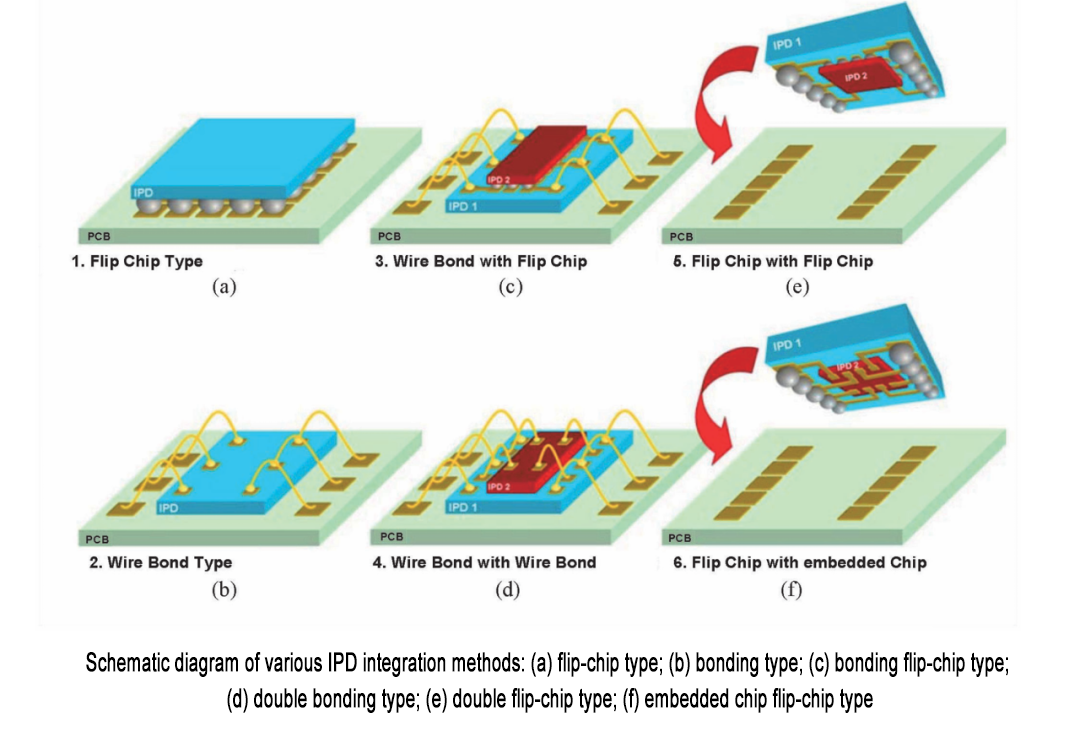

Usibye ibyiza byigiciro, ikindi cyiza cya IPD nuburyo bworoshye. Bumwe mu buryo bworoshye bwa IPD bugaragarira muburyo butandukanye bwo kwishyira hamwe, nkuko bigaragara ku gishushanyo gikurikira. Usibye uburyo bubiri bwibanze bwo kwinjiza IPD muri pake substrate binyuze muri flip-chip nkuko bigaragara ku gishushanyo (a) cyangwa inzira yo guhuza nkuko bigaragara ku gishushanyo (b), urundi rwego rwa IPD rushobora guhurizwa kumurongo umwe ya IPD nkuko bigaragara ku gishushanyo (c) - (e) kugirango ugere ku ntera yagutse y'ibikoresho byoroshye.

Muri icyo gihe kimwe, nkuko bigaragara ku gishushanyo (f), IPD irashobora gukomeza gukoreshwa nk'ikibaho cya adaptate kugira ngo ishyingurwe mu buryo butaziguye kugira ngo yubake mu buryo butaziguye sisitemu yo gupakira ibintu byinshi.

Iyo ukoresheje IPD mukubaka ibikoresho-bitatu bya pasiporo, inzira ya TSV hamwe na RDL inzira nayo irashobora gukoreshwa. Inzira igenda ahanini ni imwe nkuko byavuzwe haruguru kuri chip ihuza uburyo bwo gutunganya, kandi ntibizasubirwamo; itandukaniro ni uko kuva ikintu cyo kwishyira hamwe cyahinduwe kiva kuri chip kijya ku kibaho cya adapter, nta mpamvu yo gutekereza ku ngaruka ziterwa nuburyo butatu bwo gupakira ku gice gikora no guhuza ibice. Ibi kandi biganisha ku kindi kintu cyingenzi cya IPD: ibikoresho bitandukanye bya substrate birashobora guhitamo byoroshye ukurikije igishushanyo mbonera cyibikoresho byoroshye.

Ibikoresho bya substrate biboneka kuri IPD ntabwo aribikoresho bisanzwe bya semiconductor gusa nka Si na GaN, ariko kandi nubutaka bwa Al2O3, ubukonje buke / ubushyuhe buke-bufatanije hamwe nubutaka, ibirahuri, nibindi. ibikoresho byahujwe na IPD.

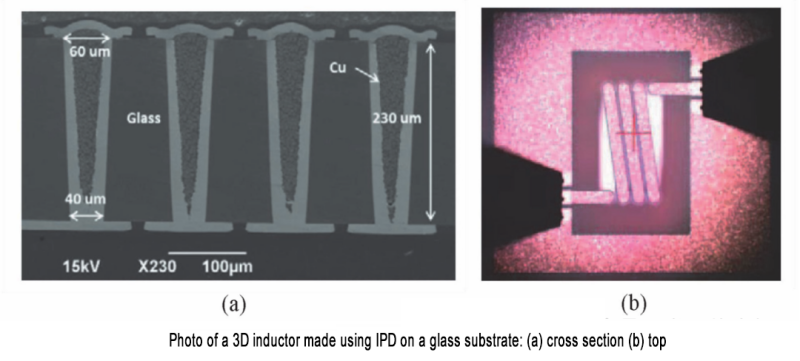

Kurugero, ibyiciro bitatu-byimikorere ya pasiporo inductor ihujwe na IPD irashobora gukoresha substrate yikirahure kugirango itezimbere imikorere yimikorere. Bitandukanye n'igitekerezo cya TSV, kunyura mu mwobo bikozwe ku kirahure cy'ikirahure nabyo byitwa binyuze mu kirahure (TGV). Ifoto ya inductor-itatu-yakozwe yakozwe ishingiye kuri IPD na TGV irerekanwa mumashusho hepfo. Kubera ko kwihanganira ibirahuri byikirahure biri hejuru cyane ugereranije nibikoresho bisanzwe bya semiconductor nka Si, inductor ya TGV-itatu-ifite induction nziza, kandi igihombo cyo kwinjiza cyatewe ningaruka ya parasitike ya parasitike kuri radiyo nini ni nto cyane kuruta iyo ibisanzwe TSV-inductor-itatu.

Ku rundi ruhande, ibyuma bifata ibyuma (insimburangingo-ibyuma) (MIM) birashobora kandi gukorerwa ku kirahuri cya substrate IPD binyuze mu buryo bworoshye bwo kohereza firime, kandi bigahuzwa na TGV ya inductor-itatu kugira ngo ibe ifite ibice bitatu-byuzuye bya filtri. Kubwibyo, inzira ya IPD ifite uburyo bwagutse bwo gukoresha mugutezimbere ibikoresho bishya bitatu-bipima passiyo.

Igihe cyo kohereza: Ugushyingo-12-2024