Carbide ya silicon (SiC) ifite inenge nyinshi zibuza gutunganywa neza. Kugirango ukore chip wafers, firime yihariye imwe-kristu igomba guhingwa kuri substrate ya SiC binyuze muburyo bwa epitaxial. Iyi firime izwi nka epitaxial layer. Ibikoresho hafi ya byose bya SiC bigerwaho kubikoresho bya epitaxial, kandi ibikoresho byiza bya homoepitaxial SiC nibyo shingiro ryiterambere ryibikoresho bya SiC. Imikorere yibikoresho bya epitaxial igena neza imikorere yibikoresho bya SiC.

Ibikoresho bigezweho kandi byizewe cyane bya SiC bishyiraho ibisabwa bikomeye hejuru yimiterere ya morfologiya, ubucucike bwinenge, uburinganire bwa doping, hamwe nuburinganire bwaepitaxialibikoresho. Kugera ku bunini bunini, buke buke, hamwe na epitaxy ya SiC ihuriweho cyane byabaye ingirakamaro mu iterambere ry’inganda za SiC.

Gukora epitaxy yo mu rwego rwo hejuru ya SiC ishingiye kubikorwa bigezweho. Kugeza ubu, uburyo bukoreshwa cyane mukuzamuka kwa epitaxial niKubika imyuka ya chimique (CVD).CVD itanga igenzura ryuzuye kubyerekeranye na epitaxial firime yubunini hamwe nubushakashatsi bwa doping, ubwinshi bw inenge, umuvuduko muke wikigereranyo, hamwe no kugenzura uburyo bwikora, bigatuma ikoranabuhanga ryizewe mubikorwa byubucuruzi byatsinze.

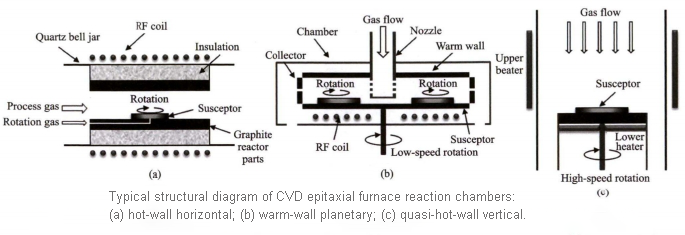

SiC CVD epitaxymuri rusange ikoresha ibikoresho bishyushye cyangwa urukuta rwa CVD ibikoresho. Ubushyuhe bwo hejuru cyane (1500–1700 ° C) butuma hakomeza kubaho imiterere ya 4H-SiC. Ukurikije isano iri hagati yicyerekezo cya gazi nubuso bwa substrate, ibyumba byerekana reaction zizi sisitemu ya CVD birashobora gushyirwa mubice bitambitse kandi bihagaritse.

Ubwiza bwamashyiga ya epitaxial ya SiC bugenzurwa cyane cyane kubintu bitatu: imikorere yiterambere rya epitaxial (harimo uburinganire bwuburinganire, guhuza doping, igipimo cy inenge, nigipimo cyubwiyongere), imikorere yubushyuhe bwibikoresho (harimo gushyushya / gukonjesha, ubushyuhe ntarengwa, nubushyuhe bwubushyuhe) ), hamwe nigiciro-cyiza (harimo igiciro cyibikoresho nubushobozi bwo gukora).

Itandukaniro hagati yubwoko butatu bwa SiC Epitaxial Gukura Kumuriro

1.Urukuta rushyushye Sisitemu ya CVD:

-Ibiranga:Mubisanzwe biranga sisitemu imwe-ya-nini nini yo gukura itwarwa na gaze ireremba, igera kubipimo byiza bya intra-wafer.

-Urugero rwerekana:LPE's Pe1O6, ishoboye gukora wafer yikora / gupakurura kuri 900 ° C. Azwiho umuvuduko mwinshi, umuvuduko muto wa epitaxial, hamwe na intra-wafer hamwe no guhuza ibikorwa.

-Imikorere:Kuri 4-6 santimetero 4H-SiC ya epitaxial wafers ifite uburebure bwa ≤30μm, igera ku mubyimba wa intra-wafer idahuje ≤2%, kwibanda kwa doping bidahuje ≤5%, ubucucike bwubuso bwa cm1 cm-², kandi nta nenge ifite ubuso bwubuso (2mm × 2mm selile) ≥ 90%.

-Abakora mu Gihugu: Ibigo nka Jingsheng Mechatronics, CETC 48, Amajyaruguru ya Huachuang, na Nasset Intelligent byateje imbere ibikoresho bisa n’ibikoresho bya epitaxial SiC imwe ya Wafer ifite umusaruro mwinshi.

2.Urukuta-rukuta Umubumbe wa CVD Sisitemu:

-Ibiranga:Koresha gahunda yimibumbe kugirango ukure-wafer kuri buri cyiciro, uzamure neza umusaruro.

-Icyitegererezo:AIXG5WWC ya Aixtron (8x150mm) na G10-SiC (9x150mm cyangwa 6x200mm).

-Imikorere:Kuri santimetero 6-ya 4H-SiC ya epitaxial wafers ifite umubyimba ≤10μm, igera ku gutandukana hagati ya wafer ± 2,5%, uburebure bwa intra-wafer budahuje 2%, gutandukana kwa doping hagati ya wafer ± 5%, na doping imbere kwibanda ku kudahuza <2%.

-Inzitizi:Kwemererwa kugarukira kumasoko yimbere mugihugu kubera kubura amakuru yumusaruro wibyiciro, inzitizi za tekiniki mubushyuhe no kugenzura imirima, hamwe na R&D ikomeje idashyizwe mubikorwa binini.

3. Quasi-ishyushye-urukuta Vertical CVD Sisitemu:

- Ibiranga:Koresha ubufasha bwibikoresho byo hanze kugirango byihuta byihuta byuzuzanya, kugabanya umubyimba wimbibi no kuzamura umuvuduko wubwiyongere, hamwe nibyiza byo kugenzura inenge.

- Abaserukira Icyitegererezo:Nuflare umwe-wafer EPIREVOS6 na EPIREVOS8.

-Imikorere:Kugera ku kigero cyo gukura hejuru ya 50μm / h, kugenzura ubucucike bwubuso buri munsi ya 0.1 cm-and, hamwe nuburebure bwa intra-wafer hamwe nubushakashatsi bwa doping budahuje 1% na 2,6%.

-Iterambere ryimbere mu Gihugu:Ibigo nka Xingsandai na Jingsheng Mechatronics byateguye ibikoresho bisa ariko ntibyigeze bigerwaho cyane.

Incamake

Buri bwoko butatu bwuburyo bwibikoresho byiterambere bya SiC bifite imiterere itandukanye kandi bufite ibice byisoko bishingiye kubisabwa. Hot-urukuta rutambitse CVD itanga umuvuduko wubwiyongere bukabije nubwiza buringaniye hamwe nuburinganire ariko bifite umusaruro muke kubera gutunganya wafer imwe. Umubumbe ushyushye wumubumbe wa CVD utezimbere cyane umusaruro ariko uhura nibibazo mugucunga ibintu byinshi. Quasi-ashyushye-urukuta ruhagaritse CVD iruta mugucunga inenge hamwe nuburyo bugoye kandi bisaba kubungabunga no gukora uburambe.

Uko inganda zigenda zitera imbere, gutezimbere no kuzamura muri ibi bikoresho bizatuma habaho ibishushanyo mbonera, bigira uruhare runini mu kuzuza epitaxial wafer itandukanye yubunini nibisabwa.

Ibyiza nibibi bya SiC Epitaxial Gukura Itanura

| Ubwoko bw'itanura | Ibyiza | Ibibi | Abahagarariye Inganda |

| Urukuta rushyushye Horizontal CVD | Iterambere ryihuse, imiterere yoroshye, kubungabunga byoroshye | Inzira yo kubungabunga igihe gito | LPE (Ubutaliyani), TEL (Ubuyapani) |

| Ubushyuhe-Urukuta Umubumbe wa CVD | Ubushobozi bwo gukora cyane, bukora neza | Imiterere igoye, kugenzura guhoraho bigoye | Aixtron (Ubudage) |

| Quasi-ishyushye-urukuta Vertical CVD | Kugenzura inenge nziza, igihe kirekire cyo kubungabunga | Imiterere igoye, kuyikomeza | Nuflare (Ubuyapani) |

Hamwe niterambere ryiterambere ryinganda, ubu bwoko butatu bwibikoresho bizakorwa muburyo bwiza bwo kuzamura imiterere no kuzamura, biganisha ku buryo bunononsoye ibishushanyo bihuye na epitaxial wafer itandukanye yubunini nibisabwa.

Igihe cyoherejwe: Nyakanga-19-2024