1.Ku bijyanye n'imirongo ihuriweho

1.1 Igitekerezo no kuvuka byumuzunguruko

Integrated Circuit (IC): bivuga igikoresho gihuza ibikoresho bikora nka tristoriste na diode hamwe nibintu byoroshye nka résistoriste na capacator binyuze murukurikirane rwubuhanga bwihariye bwo gutunganya.

Umuzunguruko cyangwa sisitemu "ihuriweho" kuri semiconductor (nka silicon cyangwa ibice nka gallium arsenide) wafer ukurikije imiyoboro imwe ihuza imirongo hanyuma igapakirwa mugikonoshwa kugirango ikore imirimo yihariye.

Mu 1958, Jack Kilby, wari ushinzwe kugabanya miniaturizasi y'ibikoresho bya elegitoronike muri Texas Instruments (TI), yatanze igitekerezo cyo kuzunguruka:

Ati: "Kubera ko ibice byose nka capacator, résistoriste, tristoriste, nibindi bishobora gukorwa mubikoresho bimwe, natekereje ko byashoboka ko babikora ku gice cyibikoresho bya semiconductor hanyuma nkabihuza kugirango bibe uruziga rwuzuye."

Ku ya 12 Nzeri na 19 Nzeri 1958, Kilby yarangije gukora no kwerekana ibyerekezo bya oscillator na trigger, byerekana ko havutse uruziga.

Mu 2000, Kilby yahawe igihembo cyitiriwe Nobel muri fiziki. Komite ishinzwe igihembo cyitiriwe Nobel yigeze kugira icyo ivuga ko Kilby “yashyizeho urufatiro rw'ikoranabuhanga rigezweho.”

Ishusho ikurikira irerekana Kilby hamwe na patenti yumuzunguruko:

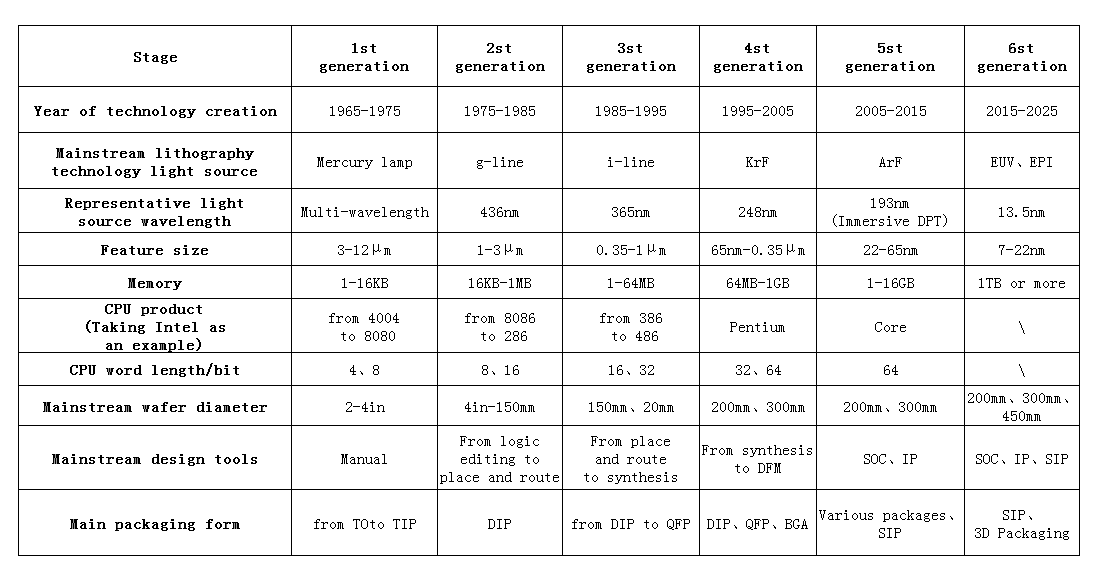

1.2 Gutezimbere tekinoroji yo gukora inganda

Igishushanyo gikurikira cyerekana ibyiciro byiterambere byikoranabuhanga rya semiconductor:

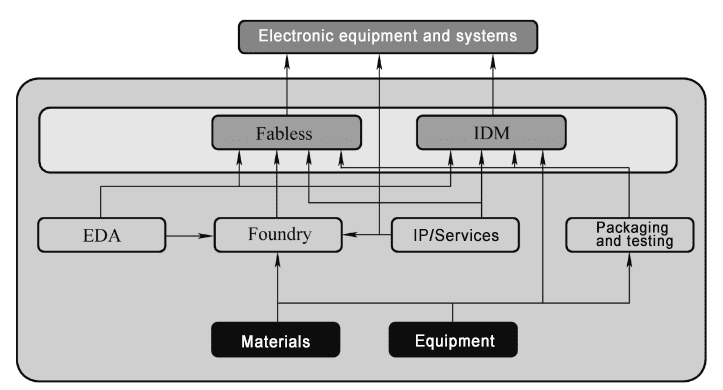

1.3 Urunigi rwinganda zuzuzanya

Ibigize urwego rwinganda zinganda (cyane cyane imiyoboro ihuriweho, harimo ibikoresho byihariye) irerekanwa mumashusho hejuru:

- Fabless: Isosiyete ikora ibicuruzwa bidafite umurongo utanga umusaruro.

- IDM: Uruganda rukora ibikoresho, rukora ibikoresho;

- IP: Uruganda rukora module;

- EDA: Igishushanyo cya elegitoroniki Automatic, elegitoroniki yogushushanya, isosiyete itanga ibikoresho byubushakashatsi;

- Uruganda; Uruganda rwa Wafer, rutanga serivisi zo gukora chip;

- Gupakira no gupima ibigo byashinzwe: cyane cyane bikorera Fabless na IDM;

- Ibikoresho nibikoresho bidasanzwe: bitanga cyane ibikoresho nibikoresho bikenerwa namasosiyete akora chip.

Ibicuruzwa byingenzi byakozwe hakoreshejwe tekinoroji ya semiconductor ni imiyoboro ihuriweho hamwe nibikoresho bya semiconductor.

Ibicuruzwa byingenzi byuzuzanya birimo:

- Gusaba Ibice byihariye bisanzwe (ASSP);

Igice cya Microprocessor (MPU);

- Kwibuka

- Gusaba Inzira Yihariye Yuzuye (ASIC);

- Inzira ya Analog;

- Inzira rusange yumuzingi (Inzira yumuzingi).

Ibicuruzwa byingenzi bya semiconductor ibikoresho byihariye birimo:

- Diode;

- Transistor;

- Igikoresho c'amashanyarazi;

- Igikoresho kinini cyane;

- Igikoresho cya Microwave;

- Optoelectronics;

- Igikoresho cya Sensor (Sensor).

2. Uburyo bwo Gukora Inzira Yuzuzanya

2.1 Gukora Chip

Ibihumbi mirongo cyangwa ibihumbi icumi byihariye birashobora gukorwa icyarimwe kuri wafer ya silicon. Umubare wa chip kuri wafer ya silicon biterwa nubwoko bwibicuruzwa nubunini bwa buri chip.

Wafer ya silicon mubisanzwe yitwa substrate. Diameter ya wafer ya silicon yagiye yiyongera uko imyaka yagiye ihita, kuva munsi ya santimetero 1 mugitangiriro kugeza kuri santimetero 12 zikoreshwa muri rusange (hafi mm 300), kandi ikaba irimo kwimuka kuri santimetero 14 cyangwa 15.

Gukora Chip muri rusange bigabanijwemo ibyiciro bitanu: gutegura wafer ya silicon, gukora wafer wa silicon, gupima chip / gutoranya, guteranya no gupakira, no kugerageza kwa nyuma.

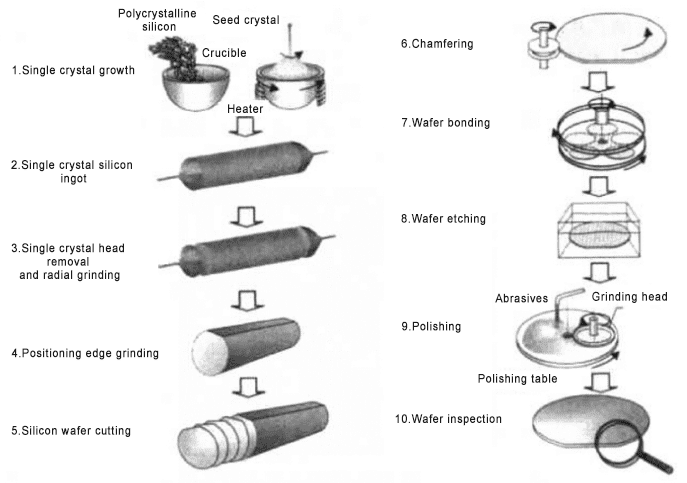

(1)

Gutegura wafer ya silicon:

Gukora ibikoresho bibisi, silikoni ikurwa mumucanga hanyuma igasukurwa. Inzira idasanzwe itanga silicon ingots ya diameter ikwiye. Ingoti zicamo ibice bya silicon yoroheje kugirango ikore microchips.

Wafers yiteguye kubisobanuro byihariye, nkibisabwa kwiyandikisha hamwe nurwego rwanduye.

(2)Silicon wafer:

Bizwi kandi nko gukora chip, wafer ya silicon yambaye ubusa igera ku ruganda rukora wa silicon wafer hanyuma ikanyura mu isuku itandukanye, gukora firime, gufotora, gufotora no gutera intambwe. Wafer yatunganijwe ya silicon ifite urutonde rwuzuye rwuzuzanya rwuzuye kuri silicon wafer.

(3)Kwipimisha no gutoranya wafer ya silicon:

Nyuma yo gukora silicon wafer irangiye, wafer ya silicon yoherejwe mukarere ka test / sort, aho chip imwe kugenzurwa no gupimwa amashanyarazi. Imipira yemewe kandi itemewe noneho iratoranywa, kandi chip ifite inenge irangwa.

(4)Inteko no gupakira:

Nyuma yo kugerageza / gutondekanya wafer, wafers yinjira mu nteko no gupakira intambwe yo gupakira chipi imwe murwego rwo gukingira. Uruhande rwinyuma rwa wafer nubutaka kugirango ugabanye ubunini bwa substrate.

Filime yuzuye ya pulasitike ifatanye inyuma ya buri wafer, hanyuma hakoreshwa icyuma cya diyama ikoreshwa mu gutandukanya imitwe kuri buri wafer ukurikije imirongo y abanditsi kuruhande rwimbere.

Filime ya plastike inyuma ya wafer ya silicon ituma chip ya silicon idagwa. Mu ruganda rwiteranirizo, chip nziza irakanda cyangwa ikimurwa kugirango ikore pake. Nyuma, chip ifunze muri plastiki cyangwa ceramic.

(5)Ikizamini gisoza:

Kugirango umenye neza imikorere ya chip, buri gipfunyika cyapimwe cyuzuzanya kirageragezwa kugirango gikore amashanyarazi asabwa nibidukikije. Nyuma yikizamini cya nyuma, chip yoherejwe kubakiriya kugirango bateranirizwe ahantu hateganijwe.

Igice cyo gutunganya

Inzira zikora zuzuzanya zigizwe muri rusange:

Imbere-Impera.

Inyuma-iherezo.

Hagati: Kugirango tunoze imikorere ya tristoriste, tekinoroji yubuhanga igezweho nyuma ya 45nm / 28nm koresha dielectrics y-k irembo ryinshi hamwe nuburyo bwo gukora amarembo yicyuma, hanyuma wongere inzira yo gusimbuza amarembo hamwe nuburyo bwo guhuza ibikorwa nyuma yinkomoko ya transistor nuburyo bwo gutunganya amazi. Izi nzira ziri hagati yimbere-yanyuma ninzira yinyuma-yanyuma, kandi ntabwo ikoreshwa mubikorwa gakondo, kubwibyo byitwa inzira yo hagati.

Mubisanzwe, inzira yo gutegura umwobo niwo ugabanya umurongo hagati yimbere-inzira yanyuma.

Umwobo: umwobo wubatswe mu buryo buhagaritse muri silicon wafer kugirango uhuze umurongo wa mbere wicyuma cyo guhuza umurongo nigikoresho cya substrate. Yuzuyemo ibyuma nka tungsten kandi bikoreshwa mukuyobora igikoresho cya electrode mugice cyuma gihuza.

Binyuze mu mwobo: Ninzira ihuza inzira ebyiri zegeranye zumurongo uhuza ibyuma, biherereye murwego rwa dielectric hagati yibyuma byombi, kandi muri rusange byuzuyemo ibyuma nkumuringa.

Mu buryo bwagutse:

Inzira y'imbere: Muburyo bwagutse, inganda zuzuzanya zigomba no gushiramo ibizamini, gupakira hamwe nizindi ntambwe. Ugereranije no kugerageza no gupakira, ibice hamwe ninganda zikorana nigice cyambere cyinganda zuzuzanya zuzuzanya, hamwe zitwa inzira yimbere;

Inzira yinyuma: Kwipimisha no gupakira byitwa inzira-yanyuma.

3. Umugereka

SMIF Inter Imigaragarire isanzwe

AMHS System Sisitemu yo gukoresha ibikoresho byikora

OHT head Kwimura hejuru

FOUP : Gufungura Imbere Pod , Byihariye kuri santimetero 12 (300mm) wafers

Icy'ingenzi,Semicera irashobora gutangaibice bya grafite, byoroshye / bikomeye,silicon karbide ibice, CVD silicon karbide ibice, naIbice bya SiC / TaChamwe na semiconductor yuzuye muminsi 30.Dutegerezanyije amatsiko kuzaba umufatanyabikorwa wawe w'igihe kirekire mu Bushinwa.

Igihe cyo kohereza: Kanama-15-2024