1. Intangiriro

Inzira yo guhuza ibintu (ibikoresho fatizo) hejuru yibikoresho byubutaka hakoreshejwe uburyo bwumubiri cyangwa imiti byitwa gukura kwa firime.

Ukurikije amahame atandukanye yakazi, guhuza imirongo yoroheje ya firime irashobora kugabanywamo:

-Kubika Imyuka Ifatika (PVD);

-Ibikoresho bya Cimical Deposition (CVD);

Kwiyongera.

2. Uburyo bwo Gukura Filime Ntoya

2.1 Gushyira imyuka yumubiri hamwe nuburyo bwo gusohoka

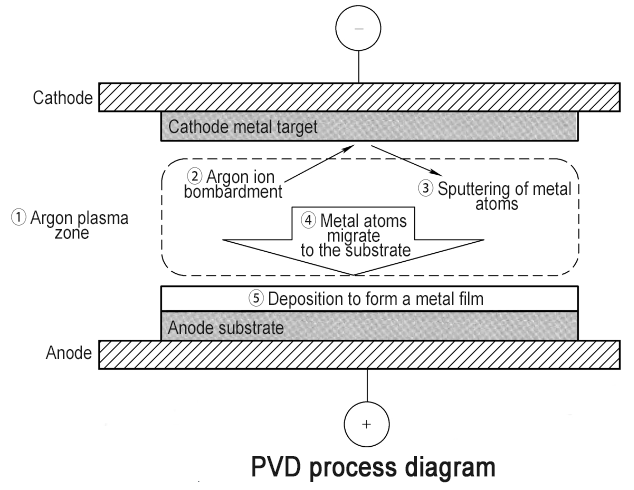

Uburyo bwo kubika imyuka yumubiri (PVD) bivuga gukoresha uburyo bwumubiri nko guhumeka kwa vacuum, sputtering, plasma coating hamwe na molekile beam epitaxy kugirango ikore firime yoroheje hejuru ya wafer.

Mu nganda za VLSI, tekinoroji ya PVD ikoreshwa cyane ni sputtering, ikoreshwa cyane cyane kuri electrode hamwe nicyuma gihuza imiyoboro ihuriweho. Gusohora ni inzira imyuka idasanzwe [nka argon (Ar)] iioni muri ion (nka Ar +) munsi yumuriro wumuriro wamashanyarazi wo hanze mugihe cyumuyaga mwinshi, kandi ugatera ibisasu isoko yibikoresho munsi yumuriro mwinshi, gukuramo atome cyangwa molekile y'ibikoresho bigenewe, hanyuma ukagera hejuru ya wafer kugirango ukore firime yoroheje nyuma yo kuguruka nta kugongana. Ar ifite imiterere ihamye yimiti, kandi ion zayo ntizitwara neza hamwe nibikoresho bigenewe na firime. Mugihe ibyuma byumuzunguruko byinjijwe byinjira mugihe cya 0.13μm cyumuringa uhuza, umuringa wibikoresho byumuringa ukoresha nitride ya titanium (TiN) cyangwa tantalum nitride (TaN). Icyifuzo cy’ikoranabuhanga mu nganda cyateje imbere ubushakashatsi n’iterambere ry’ikoranabuhanga ritera imiti, ni ukuvuga mu cyumba cy’imyuka, usibye Ar, hari na azote ya gaze (N2), ku buryo Ti cyangwa Ta batewe ibisasu bivuye intego yibikoresho Ti cyangwa Ta bifata hamwe na N2 kubyara firime ya TiN cyangwa TaN isabwa.

Hariho uburyo butatu bukoreshwa muburyo bwo gusohora, aribwo DC gusohora, RF gusohora na magnetron. Mugihe guhuza imiyoboro ihuriweho bikomeje kwiyongera, umubare wibice byibyuma byinshi byuma bigenda byiyongera, kandi ikoreshwa rya tekinoroji ya PVD riragenda ryaguka. Ibikoresho bya PVD birimo Al-Si, Al-Cu, Al-Si-Cu, Ti, Ta, Co, TiN, TaN, Ni, WSi2, n'ibindi.

Ubusanzwe PVD na sputtering byuzuzwa mubyumba bifunze cyane hamwe na vacuum ya 1 × 10-7 kugeza 9 × 10-9 Torr, ishobora kwemeza ubwiza bwa gaze mugihe cyo kubyitwaramo; icyarimwe, voltage yo hanze irasabwa ionisiyasi ya gaze idasanzwe kugirango itange ingufu nyinshi zihagije zo gutera ibisasu. Ibipimo nyamukuru byo gusuzuma PVD nuburyo bwo gusohora birimo ingano yumukungugu, kimwe nagaciro kokurwanya, uburinganire, ubunini bwikigereranyo hamwe nibibazo bya firime yakozwe.

2.2 Gutanga imyuka ya chimique hamwe nuburyo bwo gusohora

Ububiko bwa chimique (CVD) bivuga tekinoroji yuburyo bukoreshwa muburyo butandukanye bwa gaze ya gaze hamwe ningutu zinyuranye zitera imiti mubushyuhe nubushyuhe runaka, kandi ibintu bikomeye byakozwe bigashyirwa hejuru yibikoresho bya substrate kugirango ubone ubunini bwifuzwa. firime. Mubikorwa gakondo byuzuzanya bikora, ibikoresho bya firime byabonetse mubisanzwe ni ibice nka oxyde, nitride, karbide, cyangwa ibikoresho nka silikoni polycrystalline na silicon amorphous. Iterambere rya epitaxial ryatoranijwe, rikoreshwa cyane nyuma ya 45nm node, nkisoko namazi ya SiGe cyangwa Si ikura rya epitaxial, naryo ni tekinoroji ya CVD.

Iri koranabuhanga rirashobora gukomeza gukora ibikoresho bimwe bya kristu byubwoko bumwe cyangwa bisa na lattike yumwimerere kuri sisitemu imwe ya kirisiti ya silicon cyangwa ibindi bikoresho kuruhande rwumwimerere. CVD ikoreshwa cyane mukuzamura insimburangingo ya dielectric (nka SiO2, Si3N4 na SiON, nibindi) na firime yicyuma (nka tungsten, nibindi).

Muri rusange, ukurikije ibyiciro by’ingutu, CVD irashobora kugabanywa mu kirere cy’umuyaga w’umuyaga w’ikirere (APCVD), imyuka yo mu kirere y’imyuka yo mu kirere (SAPCVD) hamwe n’umuvuduko ukabije w’imyuka mvaruganda (LPCVD).

Ukurikije ubushyuhe bw’ubushyuhe, CVD irashobora kugabanywa mubushyuhe bwo hejuru / ubushyuhe buke bwa okiside ya firime ya pompe yimiti (HTO / LTO CVD) hamwe nubushyuhe bwihuse bwimyuka yumuriro (Rapid Thermal CVD, RTCVD);

Nk’uko inkomoko yabitangaje, CVD irashobora kugabanywa muri CVD ishingiye kuri silane, CVD ishingiye kuri polyester (CVD ishingiye kuri TEOS) hamwe n’ibyuma biva mu bimera biva mu kirere (MOCVD);

Ukurikije ibyiciro by’ingufu, CVD irashobora kugabanywamo imyuka yubushyuhe bwa chimique (Thermal CVD), plasma yongerewe imbaraga ziva mumashanyarazi (Plasma Enhanced CVD, PECVD) hamwe nubushyuhe bwinshi bwa plasma chimique (High Density Plasma CVD, HDPCVD). Vuba aha, imyuka ya chimique ishobora gutwarwa (Flowable CVD, FCVD) ifite ubushobozi bwiza bwo kuziba icyuho nayo yarakozwe.

Filime zitandukanye zikura CVD zifite imiterere itandukanye (nkibigize imiti, guhora dielectric, guhagarika umutima, guhangayika no guhagarika imbaraga za voltage) kandi birashobora gukoreshwa bitandukanye ukurikije ibisabwa bitandukanye (nkubushyuhe, gukwirakwiza intambwe, kuzuza ibisabwa, nibindi).

2.3 Uburyo bwo kubika atome

Ububiko bwa Atomic layer (ALD) bivuga kwishira kwa atome kumurongo ukurikije ibikoresho bya substrate ukura firime imwe ya atome ya firime kumurongo. Ubusanzwe ALD ikoresha uburyo bwo kwinjiza gaze ya preursors muri reaction muburyo busimburana.

Kurugero, ubanza, reaction ibanziriza 1 yinjijwe mubutaka bwa substrate, hanyuma nyuma ya adsorption ya chimique, urwego rumwe rwa atome rukorwa hejuru yubutaka; noneho preursor 1 isigaye hejuru yubutaka no mucyumba cya reaction isohorwa na pompe yumuyaga; noneho reaction ibanziriza 2 yinjizwa mubutaka bwa substrate, kandi muburyo bwa chimique ikora hamwe na preursor 1 yamamajwe hejuru yubutaka kugirango habeho ibikoresho bya firime yoroheje hamwe nibicuruzwa bikwiranye hejuru yubutaka; mugihe kibanziriza 1 cyitwaye neza rwose, reaction izahita irangira, aribwo kwifata wenyine biranga ALD, hanyuma reaction zisigaye hamwe nibicuruzwa bikururwa kugirango bitegure icyiciro gikurikira cyo gukura; mugusubiramo inzira yavuzwe haruguru ubudahwema, gushira ibikoresho bya firime yoroheje ikura kumurongo hamwe na atome imwe irashobora kugerwaho.

ALD na CVD byombi ni uburyo bwo kumenyekanisha imyuka ya gaze ya reaction kugirango ikore imiti hejuru yubutaka, ariko itandukaniro ni uko imyuka ya gaze ya CVD idafite imiterere yo gukura kwifata. Birashobora kugaragara ko urufunguzo rwo guteza imbere ikoranabuhanga rya ALD ari ugushaka ababanjirije bafite imiterere-yo kwigabanya.

2.4 Inzira ya Epitaxial

Epitaxial process bivuga inzira yo gukura byuzuye byateganijwe kristu imwe kuri substrate. Muri rusange, epitaxial inzira nugukuza kristu igizwe nicyerekezo kimwe cya lattice icyerekezo kimwe na substrate yumwimerere kumurongo umwe wa kristu. Epitaxial inzira ikoreshwa cyane mubikorwa bya semiconductor, nka epitaxial silicon wafers munganda zihuriweho n’umuzunguruko, isoko yashizwemo no gukura epitaxial ya transistors ya MOS, gukura kwa epitaxial kuri LED substrate, nibindi.

Ukurikije ibyiciro bitandukanye byerekana inkomoko yo gukura, uburyo bwo gukura bwa epitaxial burashobora kugabanywamo epitaxy ikomeye yicyiciro, epitaxy yamazi ya epitaxy, hamwe na epitaxy yicyuka. Mubikorwa byuzuzanya byumuzunguruko, uburyo bukoreshwa cyane epitaxial nuburyo bukomeye epitaxy nicyiciro cya epitaxy.

Icyiciro gikomeye epitaxy: bivuga gukura kwikintu kimwe cya kirisiti kuri substrate ukoresheje isoko ihamye. Kurugero, ubushuhe bwa annealing nyuma yo guterwa ion mubyukuri ni inzira ikomeye ya epitaxy. Mugihe cyo gutera ion, atome ya silicon ya wafer ya silicon yatewe ibisasu na ion zatewe ingufu nyinshi, bigasigara aho byahoze byihuta hanyuma bigahinduka amorphous, bigakora hejuru ya amorphous silicon. Nyuma yubushyuhe bwo hejuru bwubushyuhe bwo hejuru, atome ya amorphous isubira mumyanya yabyo kandi igakomeza guhuza nicyerekezo cya kirimbuzi cyerekanwe imbere muri substrate.

Uburyo bwo gukura bwimyuka yicyuka kirimo epitaxy ya chimique fapase epitaxy, molekulari beam epitaxy, atomic layer epitaxy, nibindi. Ihame ryimyuka yimyuka ya epitaxy nubusanzwe irasa niy'imyuka ya chimique. Byombi ni inzira zibika firime yoroheje mugukoresha imiti hejuru ya wafer nyuma yo kuvanga gaze.

Itandukaniro ni uko kubera ko imiti yimyuka ya epitaxy ikura igice kimwe cya kirisiti, ifite ibisabwa byinshi kubintu bitanduye mubikoresho ndetse nisuku yubuso bwa wafer. Inzira ya chimique yambere epitaxial silicon inzira igomba gukorwa mugihe cy'ubushyuhe bwinshi (burenze 1000 ° C). Hamwe nogutezimbere ibikoresho bitunganijwe, cyane cyane hifashishijwe tekinoroji yo guhanahana ibyumba bya vacuum, isuku yikibanza cyibikoresho hamwe nubuso bwa wafer ya silicon yaratejwe imbere cyane, kandi epitaxy ya silicon irashobora gukorwa mubushyuhe buke (600-700 °) C). Epitaxial silicon wafer inzira ni ugukura urwego rwa silikoni imwe ya kirisiti hejuru ya wafer ya silicon.

Ugereranije na substrate ya silicon yumwimerere, epitaxial silicon layer ifite isuku nini nudusembwa duke twa lattice, bityo bikazamura umusaruro wibyakozwe na semiconductor. Byongeye kandi, ubwiyongere bwikura hamwe nubushakashatsi bwa doping bwa epitaxial silicon layer ikura kuri wafer ya silicon irashobora gushushanywa kuburyo bworoshye, bizana guhinduka mugushushanya igikoresho, nko kugabanya kurwanya insimburangingo no kongera ubwigunge. Kwinjiza isoko-imiyoboro epitaxial ni tekinoroji ikoreshwa cyane muburyo bwa tekinoroji ya tekinoroji.

Yerekeza ku nzira yo gukura epitaxial dopi germanium silicon cyangwa silikoni mu isoko no kuvoma uturere twa MOS transistors. Ibyiza byingenzi byo kumenyekanisha isoko-imiyoboro ya epitaxial yashyizwemo harimo: gukura urwego rwa pseudocrystalline rurimo guhangayikishwa no guhuza imihindagurikire y'ikirere, kunoza urujya n'uruza rw'abatwara imiyoboro; muri-doping yinkomoko namazi birashobora kugabanya parasitike irwanya isoko-imiyoboro ihuza kandi ikagabanya inenge ziterwa ningufu nyinshi ion.

3. Ibikoresho byo gukura bya firime yoroheje

3.1 Ibikoresho byo guhumeka

Imyuka ya Vacuum nuburyo bwo gutwikira bushyushya ibikoresho bikomeye mucyumba cya vacuum kugirango bitume bishira, bikavamo umwuka cyangwa bigabanuka, hanyuma bigahuza kandi bigashyirwa hejuru yibikoresho byubutaka ku bushyuhe runaka.

Mubisanzwe igizwe nibice bitatu, aribyo sisitemu ya vacuum, sisitemu yo guhumeka hamwe na sisitemu yo gushyushya. Sisitemu ya vacuum igizwe nu miyoboro ya vacuum na pompe vacuum, kandi umurimo wacyo nyamukuru ni ugutanga icyuho cyujuje ibyangombwa byo guhumeka. Sisitemu yo guhumeka igizwe nameza yo guhumeka, igice cyo gushyushya hamwe nikigereranyo cyo gupima ubushyuhe.

Ibikoresho bigenewe guhinduka (nka Ag, Al, nibindi) bishyirwa kumeza yumwuka; ibipimo byo gushyushya n'ubushyuhe ni uburyo bufunze-bukoreshwa mu kugenzura ubushyuhe bwuka kugirango habeho guhumeka neza. Sisitemu yo gushyushya igizwe na wafer hamwe nibikoresho byo gushyushya. Icyiciro cya wafer gikoreshwa mugushira substrate aho firime yoroheje igomba guhumeka, naho ubushyuhe bukoreshwa mugushakisha ubushyuhe bwo gupima no gupima ubushyuhe bwo kugenzura.

Ibidukikije bya vacuum nibintu byingenzi cyane mubikorwa byo guhumeka, bifitanye isano nigipimo cyuka hamwe nubwiza bwa firime. Niba impamyabumenyi ya vacuum itujuje ibisabwa, atome cyangwa molekile ziva mu kirere bizahura kenshi na molekile ya gaze isigaye, bigatuma inzira yabo yubusa iba nto, kandi atome cyangwa molekile bizatatana cyane, bityo bihindure icyerekezo cyo kugenda no kugabanya firime igipimo cyo gushingwa.

Byongeye kandi, kubera ko hari molekile ya gazi isigaye isigaye, firime yabitswe iranduye cyane kandi idafite ubuziranenge, cyane cyane iyo umuvuduko w’umuvuduko w’icyumba utujuje ubuziranenge kandi hakaba hasohotse, umwuka uzinjira mu cyumba cya vacuum , bizagira ingaruka zikomeye kumiterere ya film.

Imiterere yimiterere yibikoresho byuka byuka byerekana ko uburinganire bwikibiriti ku bunini bunini ari bubi. Kugirango tunonosore uburinganire bwayo, uburyo bwo kongera intera-substrate intera no kuzunguruka substrate muri rusange byemewe, ariko kongera intera-substrate bizatanga umuvuduko wubwiyongere nubuziranenge bwa firime. Muri icyo gihe, kubera kwiyongera k'umwanya wa vacu, igipimo cyo gukoresha ibikoresho byuka kiragabanuka.

3.2 DC ibikoresho byo kubika imyuka yumubiri

Imyuka igezweho yumubiri (DCPVD) izwi kandi nka cathode sputtering cyangwa vacuum DC ibyiciro bibiri. Intego yibikoresho ya vacuum DC ikoreshwa nka cathode na substrate ikoreshwa nka anode. Vacuum sputtering nugukora plasma mugutanga ion gaz.

Ibice byashizwemo muri plasma byihuta mumashanyarazi kugirango ubone ingufu runaka. Ibice bifite ingufu zihagije zitera hejuru yibikoresho bigenewe, kuburyo atome yagenewe gusohoka; atome zasutswe hamwe ningufu za kinetic zigenda zerekeza kuri substrate kugirango zikore firime yoroheje hejuru yubutaka. Gazi ikoreshwa mu gusohora muri rusange ni gaze idasanzwe, nka argon (Ar), bityo firime yakozwe no gusohora ntizanduzwa; mubyongeyeho, radiyo ya atome ya argon irakwiriye cyane gusohora.

Ingano y'ibice bisohoka igomba kuba hafi yubunini bwa atome yagenewe gusohoka. Niba ibice ari binini cyane cyangwa bito cyane, gusohora neza ntibishobora gushingwa. Usibye ubunini bwa atom, ibintu byinshi bya atome bizagira ingaruka no kumiterere. Niba inkomoko ya sputtering inkomoko yoroheje cyane, intego atom ntizizunguruka; niba uduce duto duto turemereye cyane, intego izaba "yunamye" kandi intego ntizisohoka.

Ibikoresho bigenewe gukoreshwa muri DCPVD bigomba kuba umuyobozi. Ibi ni ukubera ko mugihe ion ya argon mugikorwa cya bombe itera ibisasu intego, bazongera kwiyunga na electron hejuru yibikoresho bigenewe. Iyo ibikoresho bigenewe ari kiyobora nkicyuma, electron zikoreshwa niyi recombination zuzuzwa byoroshye nogutanga amashanyarazi hamwe na electroni yubusa mubindi bice byibikoresho bigenewe binyuze mumashanyarazi, kuburyo ubuso bwibikoresho bigenewe nka a byose bikomeza kwishyurwa nabi kandi gusohora birakomeza.

Ibinyuranye na byo, niba ibikoresho bigenewe ari insuliranteri, nyuma ya electron hejuru yubuso bwibikoresho byongeye guhurizwa hamwe, electroni yubusa mubindi bice byibikoresho byagenewe ntishobora kuzuzwa nogukoresha amashanyarazi, ndetse nuburyo bwiza buzarundarunda kuri ubuso bwibikoresho bigenewe, bigatuma intego yibikoresho ishobora kuzamuka, hamwe nuburyo bubi bwibikoresho bigenewe bigenda bigabanuka kugeza igihe bizimiye, amaherezo biganisha ku kurangiza gusohora.

Kubwibyo, kugirango dukore ibikoresho byokoresha insuline nabyo bikoreshwa mugusohora, birakenewe gushakisha ubundi buryo bwo gusohora. Iradiyo yumurongo wa radiyo nuburyo bwo gusohora bukwiranye nintego ziyobora kandi zitayobora.

Iyindi mbogamizi ya DCPVD nuko voltage yumuriro ari mwinshi kandi ibisasu bya electron kuri substrate birakomeye. Inzira ifatika yo gukemura iki kibazo nugukoresha magnetron gusohora, so magnetron sputtering nukuri mubyukuri bifite agaciro mubikorwa byumuzunguruko.

3.3 Ibikoresho byo kubika imyuka ya RF

Imiyoboro ya radiyo yumubiri (RFPVD) ikoresha ingufu za radio nkisoko ishimishije kandi nuburyo bwa PVD bubereye ibyuma bitandukanye nibikoresho bitari ibyuma.

Imirongo isanzwe itanga amashanyarazi ya RF ikoreshwa muri RFPVD ni 13.56MHz, 20MHz, na 60MHz. Inzira nziza kandi mbi yo gutanga amashanyarazi ya RF igaragara ukundi. Iyo intego ya PVD iri mugice cyiza cyizengurutse, kubera ko ubuso bwerekanwe buri mubushobozi bwiza, electron mumyuka yikirere izatemba hejuru yintego kugirango ihindure umuriro mwiza wegeranijwe hejuru yacyo, ndetse ikomeze kwegeranya electron, gukora ubuso bwayo bubogamye; mugihe intego yo gusohora iri mubice bitazenguruka, ion nziza izagenda yerekeza kuntego kandi itabogamye igice hejuru yintego.

Ikintu gikomeye cyane ni uko umuvuduko wo kugenda wa electron mumashanyarazi ya RF wihuta cyane kuruta iyoni nziza, mugihe igihe cyicyiza cyiza na kimwe cya kabiri cyikizunguruka ni kimwe, kuburyo nyuma yumuzingi wuzuye, ubuso bwerekanwe buzaba “Net” yishyuzwa nabi. Kubwibyo, mubice bike byambere, kwishyurwa nabi kurwego rwerekanwe byerekana kwiyongera; nyuma, intego igaragara igera kubintu bibi bihamye; nyuma yaho, kubera ko kwishyuza nabi kwintego bigira ingaruka mbi kuri electron, umubare wamafaranga meza kandi mabi yakiriwe na electrode yintego akunda kuringaniza, kandi intego ikerekana amafaranga ahamye.

Duhereye kubikorwa byavuzwe haruguru, birashobora kugaragara ko inzira yo gukora voltage itari nziza ntaho ihuriye nimiterere yibikoresho bigenewe ubwayo, ubwo rero uburyo bwa RFPVD ntibushobora gukemura gusa ikibazo cyo gusohora intego, ariko kandi burahuza neza. hamwe nintego zisanzwe ziyobora ibyuma.

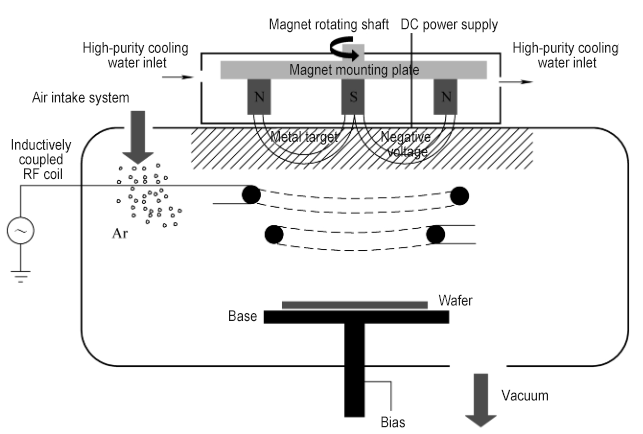

3.4 Ibikoresho bya Magnetron

Magnetron sputtering nuburyo bwa PVD bwongera magnesi inyuma yintego. Amashanyarazi yongeweho hamwe na DC itanga amashanyarazi (cyangwa amashanyarazi ya AC) sisitemu ikora magnetron. Inkomoko ya sputtering ikoreshwa mugukora amashanyarazi yumuriro wa chambre, gufata no kugabanya urwego rwimikorere ya electron muri plasma imbere yicyumba, kwagura inzira yimikorere ya electron, bityo bikongerera imbaraga za plasma, hanyuma amaherezo ukagera kuri byinshi kubitsa.

Byongeye kandi, kubera ko electron nyinshi zibohewe hafi yintego yintego, ibisasu bya substrate na electron bigabanuka, kandi ubushyuhe bwa substrate buragabanuka. Ugereranije na tekinoroji ya DCPVD ya tekinike, kimwe mu bintu bigaragara biranga tekinoroji ya magnetron yo mu kirere ni uko umuriro wo gusohora umuriro uri hasi kandi uhagaze neza.

Kubera ubwinshi bwa plasma yibanze hamwe numusaruro munini utanga umusaruro, irashobora kugera kubikorwa byiza byo kubika, kugenzura umubyimba mwinshi mubunini bunini, kugenzura neza ibihimbano hamwe na voltage yo hasi. Kubwibyo, magnetron sputtering iri mumwanya wiganje muri firime yicyuma ya PVD. Igishushanyo mbonera cyoroshye cya magnetron ni ugushira itsinda rya magneti inyuma yintego iringaniye (hanze ya sisitemu ya vacuum) kugirango habeho umurima wa rukuruzi ugereranije nubuso bwerekanwe mukarere kegereye hejuru yintego.

Niba urusaku ruhoraho rushyizwe, umurima wacyo wa magneti urahagaze neza, bigatuma igabanywa rya magneti rihagaze neza kurwego rwo hejuru mucyumba. Gusa ibikoresho mubice byihariye byintego birasakaye, igipimo cyo gukoresha intego ni gito, kandi uburinganire bwa firime yateguwe ni bubi.

Hariho amahirwe runaka yuko icyuma gisunitswe cyangwa ibindi bikoresho bizashyirwa inyuma hejuru yintego, bityo bigateranya uduce hanyuma bigatera kwanduza inenge. Kubwibyo, amasoko yubucuruzi ya magnetron yifashisha ahanini akoresha igishushanyo mbonera cya magneti kugirango azamure uburinganire bwa firime, igipimo cyo gukoresha intego, hamwe nintego yuzuye.

Ni ngombwa guhuza ibi bintu bitatu. Niba impirimbanyi idakozwe neza, irashobora kuvamo uburinganire bwa firime mugihe igabanya cyane igipimo cyo gukoresha intego (kugabanya ubuzima bugamije), cyangwa kunanirwa kugera ku ntego yuzuye cyangwa kwangirika kwuzuye, bizatera ibibazo byingingo mugihe cyo gusohora. inzira.

Muri tekinoroji ya magnetron PVD, birakenewe ko harebwa uburyo bwo kuzenguruka bwa magneti, imiterere yintego, sisitemu yo gukonjesha intego hamwe na magnetron yisuka, hamwe nuburyo bukoreshwa bwibishingwe bitwara wafer, nka adsorption ya wafer no kugenzura ubushyuhe. Mubikorwa bya PVD, ubushyuhe bwa wafer buragenzurwa kugirango ubone ibyangombwa bisabwa bya kristu, ingano yingano hamwe nicyerekezo, kimwe no guhagarara kwimikorere.

Kubera ko ubushyuhe bukorwa hagati yinyuma ya wafer nubuso bwibanze busaba igitutu runaka, mubisanzwe bikurikiranye na Torr nyinshi, kandi umuvuduko wakazi wicyumba uba uri murutonde rwa mTorr nyinshi, igitutu kumugongo ya wafer iraruta cyane umuvuduko uri hejuru ya wafer, bityo igikonoshwa cyumukanishi cyangwa amashanyarazi ya electrostatike birakenewe kugirango uhagarare kandi ugabanye wafer.

Imashini ya chuck ishingiye kuburemere bwayo no ku nkombe ya wafer kugirango igere kuriyi mikorere. Nubwo ifite ibyiza byuburyo bworoshye no kutumva ibintu bya wafer, ingaruka zanyuma za wafer ziragaragara, ibyo ntibifasha kugenzura byimazeyo ibice. Kubwibyo, yagiye isimburwa buhoro buhoro na electrostatike chuck mubikorwa bya IC.

Kubikorwa bitunvikana cyane nubushyuhe, uburyo butari adsorption, uburyo bwo guhuza amakuru (nta tandukaniro ryumuvuduko uri hagati yubuso bwo hejuru na hepfo ya wafer) nabyo birashobora gukoreshwa. Mugihe cya PVD, urugereko rwubuso hamwe nubuso bwibice bihuye na plasma bizashyirwa kandi bitwikirwe. Iyo umubyimba wa firime wabitswe urenze imipaka, firime izacika kandi ikuremo, bitera ibibazo byuduce.

Kubwibyo, hejuru yubuvuzi bwibice nkumurongo nurufunguzo rwo kwagura iyi mipaka. Gutera hejuru yumusenyi hamwe no gutera aluminiyumu nuburyo bubiri bukunze gukoreshwa, ikigamijwe ni ukongera ububobere buke kugirango ushimangire isano iri hagati ya firime nubuso.

3.5 Ionisiyonike Ibikoresho byo Kubika Imyuka

Hamwe niterambere rihoraho rya tekinoroji ya mikorobe, ingano yimiterere igenda iba nto kandi nto. Kubera ko ikoranabuhanga rya PVD ridashobora kugenzura icyerekezo cyo kohereza ibice, ubushobozi bwa PVD bwo kwinjira mu mwobo no mu miyoboro migufi hamwe n’ibipimo bihanitse ni bike, bigatuma ikoreshwa ryagutse ry’ikoranabuhanga gakondo rya PVD rigenda ritoroshye. Mubikorwa bya PVD, uko igipimo cyibice cya pore cyiyongera, ubwikingo bwo hepfo buragabanuka, bigakora imiterere isa na eva ihindagurika hejuru yinguni yo hejuru, kandi ikora intege nke cyane mugice cyo hasi.

Ikoranabuhanga rya Ionized tekinike yo kubika ryakozwe kugirango iki kibazo gikemuke. Irabanza gushira muburyo bwa atome yicyuma kiva mumigambi muburyo butandukanye, hanyuma igahindura voltage ya bias yapakiye kuri wafer kugirango igenzure icyerekezo n'imbaraga za ion zicyuma kugirango ibone icyerekezo gihamye cyicyuma kugirango itegure firime yoroheje, bityo itezimbere gukwirakwizwa hepfo yintambwe yikigereranyo kinini ugereranije nu mwobo n'inzira zifunganye.

Ibintu bisanzwe biranga tekinoroji ya plasma ya ionisiyoneri niyongerwaho rya radiyo yumurongo wa chambre. Mugihe cyibikorwa, igitutu cyakazi cyicyumba gikomeza kurwego rwo hejuru (inshuro 5 kugeza 10 zumuvuduko usanzwe wakazi). Mugihe cya PVD, coil ya radio ikoreshwa mugutanga akarere ka kabiri ka plasma, aho plasma ya argon yiyongera hamwe no kwiyongera kwingufu za radio numuvuduko wa gaze. Iyo atome y'icyuma ivuye mu ntego inyuze muri kano karere, ikorana na plasma nyinshi ya argon plasma kugirango ikore ioni.

Gukoresha isoko ya RF kubitwara wafer (nka chuck ya electrostatike) birashobora kongera kubogama kubi kuri wafer kugirango bikurura ion nziza yicyuma munsi yumwobo. Icyerekezo cyicyuma ion gitemba perpendicular hejuru yubuso bwa wafer itezimbere intambwe yo hasi yikwirakwizwa ryibice byinshi bigereranijwe hamwe nuyoboro muto.

Kubogama kubi gukoreshwa kuri wafer binatera ion gutera hejuru ya wafer (revers sputtering), bigabanya imiterere ihindagurika yumunwa wa pore kandi ikanasohora firime yashyizwe hepfo kumpande zomuruhande rwuruhande rwa pore. groove, bityo uzamura intambwe yo gukwira ku mfuruka.

3.6 Umuvuduko wa Atimosifike Ibikoresho byo kubika imyuka

Umuvuduko ukabije wa Atmospheric chimique de pompe (APCVD) bivuga igikoresho gitera imyuka ya gaze ya gazi ku muvuduko uhoraho hejuru yubutaka bukomeye bushyushye munsi y’ibidukikije hamwe n’umuvuduko uri hafi y’umuvuduko w’ikirere, bigatuma inkomoko y’ibisubizo ikora mu buryo bwa shimi kuri Ubuso bwa substrate, nibicuruzwa byabitswe bishyirwa hejuru yubutaka kugirango bibe firime yoroheje.

Ibikoresho bya APCVD nibikoresho bya mbere bya CVD kandi biracyakoreshwa cyane mubikorwa byinganda nubushakashatsi bwa siyansi. Ibikoresho bya APCVD birashobora gukoreshwa mugutegura firime zoroshye nka silikoni imwe ya kirisiti, silikoni ya polycrystalline, silicon dioxyde, okiside ya zinc, dioxyde de titanium, ikirahuri cya fosifosike, nikirahuri cya borofosifosilike.

3.7 Umuvuduko muke Ibikoresho byo kubika imyuka

Ibikoresho byo mu kirere byumuvuduko ukabije (LPCVD) bivuga ibikoresho bikoresha ibikoresho fatizo bya gaze kugirango bitange imiti hejuru yubutaka bukomeye munsi yubushyuhe (350-1100 ° C) hamwe nubushyuhe buke (10-100mTorr), kandi reaction zashyizwe hejuru yubutaka kugirango zikore firime yoroheje. Ibikoresho bya LPCVD byatejwe imbere hashingiwe kuri APCVD hagamijwe kunoza ireme rya firime zinanutse, kunoza ikwirakwizwa ryogukwirakwiza ibipimo biranga nkubunini bwa firime no kurwanya, no kunoza umusaruro.

Ikintu nyamukuru kiranga ni uko ahantu h’umuvuduko ukabije w’umuriro w’umuriro, gazi itunganyirizwa mu buryo bwa shimi hejuru yubutaka bwa wafer, kandi ibicuruzwa bivamo ibintu bigashyirwa hejuru yubutaka kugirango bibe firime yoroheje. Ibikoresho bya LPCVD bifite ibyiza mugutegura firime nziza cyane kandi irashobora gukoreshwa mugutegura firime zoroshye nka okiside ya silicon, nitride ya silicon, polysilicon, karbide ya silicon, gallium nitride na graphene.

Ugereranije na APCVD, ibidukikije byumuvuduko ukabije wibikoresho bya LPCVD byongera inzira yubusa hamwe na coefficient ya gaze ya gaze mubyumba byabigenewe.

Gazi ya reaction hamwe na molekile ya gaze itwara mucyumba cya reaction irashobora kugabanwa neza mugihe gito, bityo bikazamura cyane uburinganire bwamafirime, guhuza imbaraga hamwe no gukwirakwiza intambwe ya firime, kandi no gukoresha gaze ya reaction nayo ni nto. Byongeye kandi, ibidukikije bifite umuvuduko muke nabyo byihutisha ihererekanyabubasha ryibintu bya gaze. Umwanda hamwe nigisubizo cyibicuruzwa bitandukanijwe na substrate birashobora gukurwa vuba mukarere ka reaction binyuze kumurongo wimbibi, kandi gaze ya reaction ihita inyura kumupaka kugirango igere hejuru yubutaka kugirango ibe reaction, bityo igahagarika neza kwifata, kwitegura firime nziza-nziza hamwe na zone yinzibacyuho ihanamye, kandi inazamura umusaruro.

3.8 Ibikoresho bya plasma byongerewe ibikoresho byo kubika imyuka

Plasma yongerewe imbaraga mumashanyarazi (PECVD) nikoreshwa cyane thin tekinoroji yo kubitsa. Mugihe cya plasma, progaramu ya gaze ya ionisiyonike ikorwa na plasma kugirango ikore amatsinda ashimishije, ikwirakwira hejuru yubutaka hanyuma ikagira imiti kugirango irangize gukura kwa firime.

Ukurikije inshuro zibyara plasma, plasma ikoreshwa muri PECVD irashobora kugabanywamo ubwoko bubiri: plasma yumurongo wa radio (plasma ya RF) na plasma ya microwave (plasma ya Microwave). Kugeza ubu, radiyo ikoreshwa mu nganda muri rusange ni 13.56MHz.

Itangizwa rya plasma yumurongo wa radio mubisanzwe bigabanyijemo ubwoko bubiri: guhuza ubushobozi (CCP) no guhuza inductive (ICP). Uburyo bwa capacitive guhuza uburyo busanzwe nuburyo bwa plasma butaziguye; mugihe uburyo bwo guhuza inductive bushobora kuba uburyo bwa plasma butaziguye cyangwa uburyo bwa kure bwa plasma.

Mubikorwa byo gukora semiconductor, PECVD ikoreshwa mugukuza firime zoroshye kuri substrate zirimo ibyuma cyangwa izindi nyubako zita ku bushyuhe. Kurugero, mubijyanye nicyuma-cyuma cyuma gihuza imiyoboro ihuriweho, kuva inkomoko, amarembo nuburyo bwo kuvoma ibikoresho byashizweho muburyo bwimbere, imikurire ya firime yoroheje murwego rwo guhuza ibyuma ni ingingo. Kuri cyane ingengo yimari yubushyuhe bukabije, kubwibyo birangirana nubufasha bwa plasma. Muguhindura ibipimo bya plasma, ubucucike, ibigize imiti, ibirimo umwanda, ubukana bwa mashini hamwe nibipimo bya stress ya firime yoroheje yakuwe na PECVD irashobora guhindurwa no gutezimbere murwego runaka.

3.9 Ibikoresho byo kubika Atome

Ububiko bwa Atomic layer (ALD) ni tekinoroji yoroheje yo kubika firime ikura rimwe na rimwe muburyo bwa quasi-monoatomic. Ikiranga ni uko umubyimba wa firime wabitswe ushobora guhinduka neza mugucunga umubare wikizunguruka. Bitandukanye nuburyo bwo gutumura imyuka ya chimique (CVD), bibiri (cyangwa byinshi) bibanziriza inzira ya ALD bigenda bisimburana hejuru yubutaka kandi bigatandukanwa neza nogusukura gaze idasanzwe.

Ababanjirije bombi ntibazavanga no guhurira mugice cya gaze kugirango bakore imiti, ahubwo bazitwara gusa binyuze mumiti ya adsorption hejuru yubutaka. Muri buri cyiciro cya ALD, ingano yabanjirije iyamamaza hejuru yubutaka ifitanye isano nubucucike bwamatsinda akora hejuru yubutaka. Iyo amatsinda atagaragara hejuru yubutaka arangije, nubwo hatangijwe ibirenze ibanzirizasuzuma, imiti ya adsorption ntishobora kubaho hejuru yubutaka.

Iyi reaction yuburyo bwiswe ubuso bwigenga. Ubu buryo bwo gutunganya butuma ubunini bwa firime ikura muri buri cyiciro cyibikorwa bya ALD bihoraho, bityo inzira ya ALD ifite ibyiza byo kugenzura neza umubyimba no gukwirakwiza film neza.

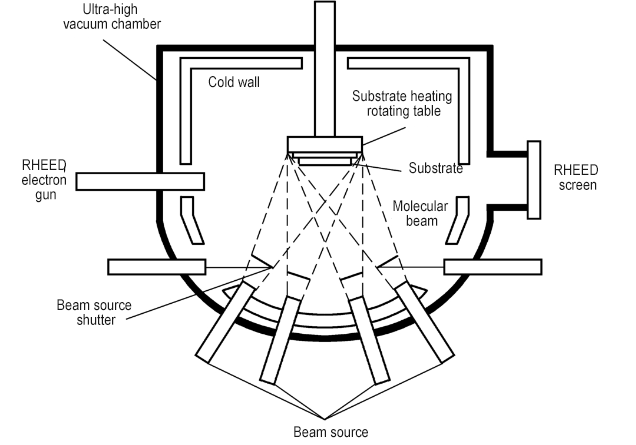

3.10 Ibikoresho bya molekulari yamashanyarazi

Sisitemu ya Molecular Beam Epitaxy (MBE) bivuga igikoresho cya epitaxial ikoresha ingufu imwe cyangwa nyinshi zumuriro wa atome cyangwa urumuri rwa molekile kugirango utere hejuru yubushyuhe bwihuse kumuvuduko runaka mubihe bidasanzwe bya vacuum, kandi adsorb ikimuka hejuru yubutaka. Kuri epitaxically gukura firime imwe ya kristu yoroheje ikurikiranye na kristu yerekana icyerekezo cyibikoresho. Mubisanzwe, muburyo bwo gushyukwa nitanura ryindege hamwe ningabo ikingira ubushyuhe, isoko yumurabyo ikora urumuri rwa atome cyangwa urumuri rwa molekile, kandi firime ikura kumurongo ukurikije icyerekezo cya kristu cyerekezo cyibikoresho bya substrate.

Ibiranga ni ubushyuhe bukabije bwo gukura, kandi ubunini, intera, imiterere yimiti hamwe nubushakashatsi bwanduye birashobora kugenzurwa neza kurwego rwa atome. Nubwo MBE yakomotse ku itegurwa rya semiconductor ultra-thin firime imwe ya kirisiti, ubu ikoreshwa ryayo ryagutse kugera kuri sisitemu zitandukanye zifatika nk'ibyuma ndetse na insimburangingo ya dielectrics, kandi irashobora gutegura III-V, II-VI, silicon, germanium (SiGe) ), graphene, oxyde na firime ngenga.

Sisitemu ya molekulari ya epitaxy (MBE) igizwe ahanini na sisitemu ya ultra-high vacuum sisitemu, isoko ya molekile yamashanyarazi, sisitemu yo gutunganya no gushyushya ibintu, sisitemu yo kwimura icyitegererezo, sisitemu yo kugenzura aho iri, sisitemu yo kugenzura, hamwe nikizamini Sisitemu.

Sisitemu ya vacuum ikubiyemo pompe vacuum (pompe yubukanishi, pompe ya molekile, pompe ion, na pompe ya kondegene, nibindi) hamwe na valve zitandukanye, zishobora gukora ibidukikije bikura cyane. Impamyabumenyi ishobora kugerwaho muri rusange ni 10-8 kugeza 10-11 Torr. Sisitemu ya vacuum ahanini ifite ibyumba bitatu bikoreramo vacuum, aribyo icyumba cyo guteramo icyitegererezo, icyumba cyo kwitegura no gusesengura hejuru, hamwe nicyumba cyo gukura.

Icyumba cyo guteramo icyitegererezo gikoreshwa mu kwimura ingero ku isi kugira ngo habeho icyuho kinini cy’ibindi byumba; icyumba cyo kwitegura no gusesengura hejuru gihuza icyumba cyo gutera inshinge nicyumba cyo gukura, kandi umurimo wacyo nyamukuru ni ugutunganya mbere yicyitegererezo (ubushyuhe bwo hasi cyane kugirango habeho isuku yuzuye yubutaka) no gukora isesengura ryibanze kuri icyitegererezo gisukuye; urugereko rwo gukura nigice cyibanze cya sisitemu ya MBE, igizwe ahanini nitanura ryinkomoko hamwe ninteko ijyanye nayo, icyitegererezo cyo kugenzura, sisitemu yo gukonjesha, kwerekana imbaraga nyinshi za electronique (RHEED), hamwe na sisitemu yo kugenzura aho biri; . Ibikoresho bimwe MBE ibikoresho bifite ibyumba byinshi byo gukura. Igishushanyo mbonera cyimiterere yibikoresho bya MBE cyerekanwe hepfo:

MBE y'ibikoresho bya silikoni ikoresha silikoni-isukuye cyane nkibikoresho fatizo, ikura mugihe cya ultra-high vacuum (10-10 ~ 10-11Torr), naho ubushyuhe bwo gukura ni 600 ~ 900 ℃, hamwe na Ga (P-ubwoko) na Sb ( N-ubwoko) nkisoko ya doping. Bikunze gukoreshwa doping isoko nka P, As na B ntibikunze gukoreshwa nkamasoko yibiti kuko bigoye guhumeka.

Icyumba cya reaction ya MBE gifite ibidukikije bya ultra-high vacuum ibidukikije, byongera inzira yubusa ya molekile kandi bikagabanya kwanduza no okiside hejuru yibintu bikura. Ibikoresho bya epitaxial byateguwe bifite isura nziza yimiterere nuburinganire, kandi birashobora gukorwa muburyo butandukanye hamwe na doping zitandukanye cyangwa ibintu bitandukanye.

Ikoranabuhanga rya MBE rigera ku gukura kwinshi kwa ultra-thin epitaxial layer hamwe nubunini bwurwego rumwe rwa atome, kandi intera iri hagati ya epitaxial irakomeye. Itera imbere gukura kwa III-V igice cya kabiri hamwe nibindi bikoresho byinshi bitandukanye. Kugeza ubu, sisitemu ya MBE yahindutse ibikoresho bigezweho byo gutunganya umusaruro mushya wibikoresho bya microwave nibikoresho bya optoelectronic. Ibibi byikoranabuhanga rya MBE ni umuvuduko witerambere rya firime, ibisabwa byinshi bya vacuum, nibikoresho bikoreshwa nibikoresho bikoresha amafaranga.

3.11 Sisitemu yo mu cyiciro cya Epitaxy

Sisitemu yo mu bwoko bwa vapor epitaxy (VPE) bivuga igikoresho cyo gukura cya epitaxial itwara imyuka ya gaze kuri substrate kandi ikabona ikintu kimwe cya kirisiti hamwe na gahunda ya lattike imwe na substrate ikoresheje reaction ya chimique. Igice cya epitaxial gishobora kuba urwego rwa homoepitaxial (Si / Si) cyangwa urwego rwa heteroepitaxial (SiGe / Si, SiC / Si, GaN / Al2O3, nibindi). Kugeza ubu, tekinoroji ya VPE yakoreshejwe cyane mubijyanye no gutegura nanomaterial, ibikoresho byamashanyarazi, ibikoresho bya semiconductor optoelectronic ibikoresho, amashanyarazi yizuba, hamwe nizunguruka.

Ubusanzwe VPE ikubiyemo epitaxy yumuvuduko wikirere no kugabanya epitaxy yumuvuduko ukabije, imyuka ihumeka ya ultra-high vacuum chimique, ibyuma byangiza imyuka ya chimique, nibindi byingenzi. kugenzura umuvuduko no gutuza, kugenzura no kugenzura inenge, nibindi.

Kugeza ubu, icyerekezo cyiterambere cyibikorwa byingenzi byubucuruzi VPE nuburyo bunini bwo gupakira, kugenzura byikora, no kugenzura igihe nyacyo cyubushyuhe niterambere. Sisitemu ya VPE ifite imiterere itatu: ihagaritse, itambitse na silindrike. Uburyo bwo gushyushya burimo gushyushya ubushyuhe, gushyushya inshuro nyinshi no gushyushya imirasire.

Kugeza ubu, sisitemu ya VPE ahanini ikoresha imiterere ya disiki itambitse, ifite ibiranga uburinganire bwiza bwikura rya epitaxial film hamwe na wafer nini. Sisitemu ya VPE mubusanzwe igizwe nibice bine: reaction, sisitemu yo gushyushya, sisitemu ya gazi na sisitemu yo kugenzura. Kuberako igihe cyo gukura cya GaAs na GaN epitaxial firime ari ndende, gushyushya induction hamwe no gushyushya birwanya bikoreshwa. Muri silicon VPE, gukura kwa epitaxial ya firime ahanini ikoresha ubushyuhe bwa induction; gukura kwa epitaxial firime ahanini ikoresha ubushyuhe bwa infragre kugirango ugere ku ntego yo kuzamuka kwinshi / kugwa.

3.12 Sisitemu yo mu cyiciro cya Epitaxy

Sisitemu ya Liquid Phase Epitaxy (LPE) bivuga ibikoresho byo gukura epitaxial ikuraho ibikoresho bigomba gukura (nka Si, Ga, As, Al, nibindi) na dopants (nka Zn, Te, Sn, nibindi) muri a icyuma hamwe no gushonga hasi (nka Ga, Muri, nibindi), kugirango igisubizo cyuzure cyangwa kirengeje urugero mumashanyarazi, hanyuma substrate imwe ya kristu ihuzwa nigisubizo, kandi igisubizo ni imvura iva mumashanyarazi mugukonja buhoro buhoro, kandi igice cyibikoresho bya kirisiti gifite imiterere ya kristu hamwe na lattice ihora isa nkiya substrate ikura hejuru yubutaka.

Uburyo bwa LPE bwatanzwe na Nelson n'abandi. mu 1963. Ikoreshwa mu gukura firime ya firime yoroheje hamwe nibikoresho bya kristu imwe, hamwe nibikoresho bya semiconductor nka matsinda ya III-IV hamwe na mercure cadmium telluride, kandi irashobora gukoreshwa mugukora ibikoresho bitandukanye bya optoelectronic, ibikoresho bya microwave, ibikoresho bya semiconductor na selile izuba .

——————————————————————————————————————— ————————————-

Semicera irashobora gutangaibice bya grafite, byoroshye / bikomeye, silicon karbide ibice, CVD silicon karbide ibice, naIbice bya SiC / TaChamwe n'iminsi 30.

Niba ushimishijwe n'ibicuruzwa byavuzwe haruguru,nyamuneka ntutindiganye kutwandikira ubwambere.

Tel: + 86-13373889683

WhatsAPP: + 86-15957878134

Email: sales01@semi-cera.com

Igihe cyo kohereza: Kanama-31-2024