Wafers nibikoresho byingenzi byibanze byo gukora imiyoboro ihuriweho, ibikoresho bya semiconductor discret hamwe nibikoresho byamashanyarazi. Kurenga 90% byumuzunguruko wakozwe bikozwe hejuru-yera cyane.

Ibikoresho byo gutegura Wafer bivuga inzira yo gukora ibikoresho bya silikoni nziza ya silikoni mubikoresho bya silicon imwe ya kristu yinkoni ya diametre nuburebure, hanyuma ugashyira ibikoresho bya silicon imwe yibikoresho bya kristu muburyo bwo gutunganya imashini, kuvura imiti nibindi bikorwa.

Ibikoresho bikora wafer ya silicon cyangwa epitaxial silicon wafers yujuje uburinganire bwa geometrike hamwe nubuziranenge bwubutaka kandi itanga insimburangingo isabwa kugirango ikorwe.

Inzira isanzwe yo gutegura wafer ya silicon ifite diameter iri munsi ya 200 mm ni:

Gukura kristu imwe → gucamo → kuzenguruka diameter yo hanze → gukata → gukubita → gusya → guswera → kubona → guswera → gusukura → epitaxy → gupakira, nibindi.

Inzira nyamukuru itemba yo gutegura wafer ya silicon ifite diameter ya mm 300 niyi ikurikira:

Gukura kristu imwe → gucamo → kuzenguruka diameter yo hanze → gukata → gukandagira → gusya hejuru

1.Ibikoresho bya silicon

Silicon nigikoresho cya semiconductor kuko ifite electroni 4 za valence kandi iri mumatsinda ya IVA kumeza yibihe hamwe nibindi bintu.

Umubare wa electroni ya valence muri silicon uyishyira neza hagati yumuyobora mwiza (1 valence electron) na insulator (8 electronique).

Silicon isukuye ntabwo iboneka muri kamere kandi igomba gukururwa no kwezwa kugirango ikorwe bihagije kugirango ikorwe. Ubusanzwe iboneka muri silika (oxide silicon cyangwa SiO2) hamwe na silicates.

Ubundi buryo bwa SiO2 burimo ikirahure, kirisiti itagira ibara, quartz, agate nijisho ryinjangwe.

Ibikoresho bya mbere byakoreshejwe nka semiconductor ni germanium mu myaka ya za 1940 no mu ntangiriro ya 1950, ariko yahise isimburwa na silicon.

Silicon yatoranijwe nkibikoresho byingenzi bya semiconductor kubwimpamvu enye zingenzi:

Ubwinshi bwibikoresho bya Silicon: Silicon nikintu cya kabiri cyinshi cyane kwisi, bingana na 25% byubutaka bwisi.

Ingingo yo hejuru yo gushonga yibikoresho bya silicon ituma kwihanganira inzira yagutse: aho gushonga kwa silikoni kuri 1412 ° C irarenze cyane aho gushonga kwa germanium kuri 937 ° C. Ingingo yo hejuru yo gushonga yemerera silikoni kwihanganira ubushyuhe bwo hejuru.

Ibikoresho bya Silicon bifite ubushyuhe bwagutse bwo gukora;

Gukura bisanzwe kwa silicon oxyde (SiO2). Guhagarika amashanyarazi ni ngombwa kugirango wirinde kumeneka hagati yabatwara hafi yumuzunguruko. Ubushobozi bwo gukura buhoro buhoro bwibikoresho bya SiO2 nibyingenzi mugukora ibikoresho-byuma-oxyde semiconductor (MOS-FET). SiO2 ifite imiterere yubukorikori isa na silicon, ituma ubushyuhe bwo hejuru butagira silikoni wafer ikabije.

2.Imyiteguro myiza

Wafers ya Semiconductor yaciwe mubikoresho byinshi bya semiconductor. Ibikoresho bya semiconductor byitwa inkoni ya kristu, ikura kuva kumurongo munini wa polycrystalline hamwe nibikoresho bidafunguye.

Guhindura polycrystalline mumurongo munini wa kristu hanyuma ukayiha icyerekezo cyiza cya kristu hamwe nubunini bukwiye bwa N-bwoko cyangwa P-doping byitwa gukura kwa kristu.

Ikoranabuhanga risanzwe ryo gukora intungamubiri imwe ya kirisiti ya silicon yo gutegura silicon wafer nuburyo bwa Czochralski nuburyo bwo gushonga zone.

2.1 Uburyo bwa Czochralski hamwe na Czochralski itanura rimwe

Uburyo bwa Czochralski (CZ), buzwi kandi ku buryo bwa Czochralski (CZ), bivuga inzira yo guhindura amazi ya silicon yo mu rwego rwa silicon yashizwemo ibintu bikomeye bya kirisiti ya silikoni ifite icyerekezo cyiza cya kristu hanyuma ikandikwa muri N-bwoko cyangwa P- Ubwoko.

Kugeza ubu, hejuru ya 85% ya silikoni imwe ya kirisiti ihingwa hakoreshejwe uburyo bwa Czochralski.

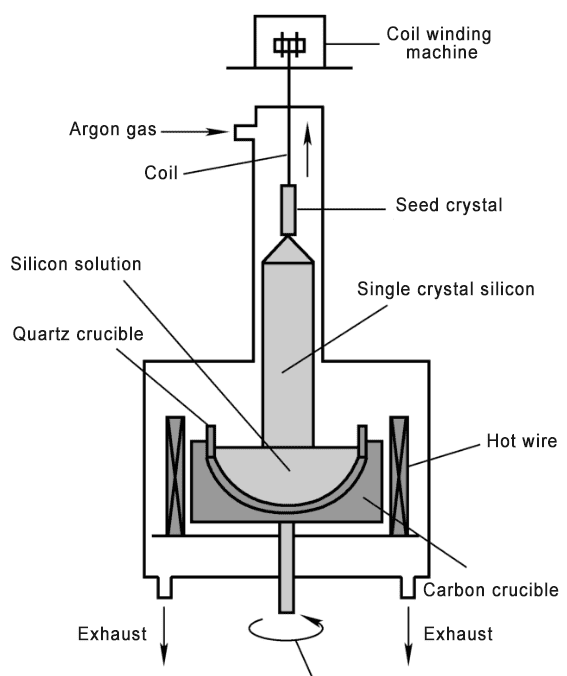

Itanura rimwe rya Czochralski ryerekeza ku bikoresho bitunganyirizwa mu gushonga ibikoresho bya polysilicon bifite isuku nyinshi mu mazi ashyushya mu cyuho kinini gifunze cyangwa gaze idasanzwe (cyangwa gazi ya inert), hanyuma ikongera ikabishyira mu bikorwa kugira ngo ikore ibikoresho bya kirisiti imwe ya kirisiti hamwe n’ibindi byo hanze ibipimo.

Ihame ryakazi ry itanura rimwe rya kirisiti ni inzira yumubiri ya polycrystalline silicon ibikoresho byongeye kwinjizwa mubintu bya kirisiti ya kirisiti imwe mumazi.

Itanura rya CZ imwe ya kirisiti irashobora kugabanywamo ibice bine: umubiri w itanura, sisitemu yo gukwirakwiza imashini, uburyo bwo gushyushya no kugenzura ubushyuhe, hamwe na sisitemu yohereza gaze.

Umubiri w'itanura urimo urwobo rw'itanura, imbuto ya kirisiti ya kirisiti, quartz ikomeye, ikiyiko cya doping, igipfundikizo cy'imbuto, n'idirishya ryo kureba.

Umuyoboro w'itanura ni ukureba ko ubushyuhe bwo mu itanura bwagabanijwe neza kandi bushobora gukwirakwiza ubushyuhe neza; imbuto ya kirisiti ikoreshwa mugutwara imbuto kristu kugirango izamuke hejuru no kuzunguruka; umwanda ugomba gukopororwa ushyirwa mu kiyiko cya doping;

Igipfukisho c'imbuto ya kirisiti ni ukurinda imbuto kristu kwanduza. Sisitemu yo gukwirakwiza imashini ikoreshwa cyane cyane mugucunga urujya n'uruza rw'imbuto na kirisiti.

Kugirango harebwe niba igisubizo cya silicon kidahinduka okiside, impamyabumenyi ya vacuum mu itanura isabwa kuba hejuru cyane, muri rusange munsi ya 5 Torr, kandi ubwiza bwa gaze yongeweho igomba kuba hejuru ya 99,9999%.

Igice cya silikoni imwe ya kirisiti hamwe nicyerekezo cya kirisiti yifuzwa ikoreshwa nka kristu yimbuto kugirango ikure ingoti ya silicon, naho ingunguru ya silicon ikuze ni nka kopi yimbuto ya kristu.

Imiterere iri hagati ya silicon yashongeshejwe hamwe nimbuto imwe ya kirisiti ya kirisiti ya kirisiti igomba kugenzurwa neza. Ibi bintu byemeza neza ko urwego ruto rwa silikoni rushobora kwigana neza imiterere yimbuto ya kristu hanyuma amaherezo ikura ikaba nini nini ya kirisiti ya silicon.

2.2 Uburyo bwo Gushonga Zone na Zone Gushonga Zone imwe ya Crystal Itanura

Uburyo bwa float zone (FZ) butanga ingirabuzimafatizo imwe ya kirisiyumu hamwe na ogisijeni nkeya cyane. Uburyo bwa float zone bwatunganijwe mu myaka ya za 1950 kandi bushobora kubyara silikoni imwe isukuye kugeza ubu.

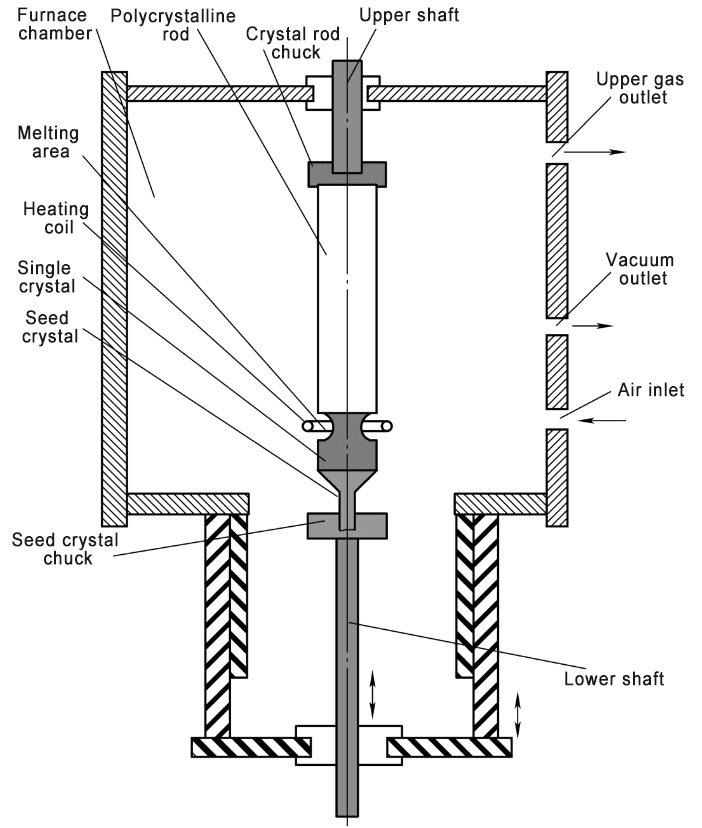

Agace gashonga itanura imwe ya kirisiti bivuga itanura rikoresha ihame ryo gushonga rya zone kugirango habeho akarere gashonga mu nkoni ya polycrystalline binyuze mu bushyuhe bwo hejuru bwagutse ahantu hafunze umubiri wa polycrystalline mu itanura ryinshi cyangwa gaze ya gaze ya quartz idasanzwe. ibidukikije.

Ibikoresho bitunganyirizwa inkoni ya polycrystalline cyangwa umubiri ushyushya itanura kugirango yimure akarere gashonga hanyuma gahoro gahoro uyihinduramo inkoni imwe ya kirisiti.

Ikiranga gutegura inkoni imwe ya kirisiti hakoreshejwe uburyo bwo gushonga zone nuko isuku yinkoni ya polycristaline ishobora kunozwa mugikorwa cyo korohereza kristu imwe, kandi gukura kwa doping kwibikoresho byinkoni birasa.

Ubwoko bwa zone ishonga itanura imwe ya kirisiti irashobora kugabanwa muburyo bubiri: zone ireremba gushonga itanura imwe ya kirisiti ishingiye kumyuka yubuso hamwe na zone itambitse gushonga itanura rimwe. Mubikorwa bifatika, zone ishonga itanura imwe ya kirisiti muri rusange ifata akarere kareremba.

Agace gashonga itanura imwe ya kirisiti irashobora gutegura ubuziranenge-buke bwa ogisijeni nkeya ya kirisiti ya kirisiti idakenewe cyane. Ikoreshwa cyane cyane mugutegura-kwihanganira cyane (> 20kΩ · cm) silikoni imwe ya kirisiti no kweza zone gushonga silicon. Ibicuruzwa bikoreshwa cyane mugukora ibikoresho byingufu zidasanzwe.

Agace gashonga itanura imwe ya kirisiti igizwe nicyumba cy itanura, uruzitiro rwo hejuru hamwe nigitereko cyo hepfo (igice cyogukwirakwiza imashini), inkoni ya kirisiti ya christal chuck, imbuto ya kristu yimbuto, igiceri gishyushya (generator yumurongo mwinshi), ibyambu bya gaze (icyambu cya vacuum, gaze ya gaze, isohoka rya gaze hejuru), nibindi

Mu cyumba cy'itanura cyubatswe, hateguwe amazi akonje. Impera yo hepfo yigitereko cyo hejuru cy itanura imwe ya kirisiti ni inkoni ya kirisiti ya christal, ikoreshwa mugukata inkoni ya polycristaline; impera yo hejuru yigitereko cyo hasi ni imbuto ya kristu ya chuck, ikoreshwa mugukata imbuto kristu.

Amashanyarazi menshi cyane atangwa kuri coil yo gushyushya, kandi agace kagufi gashonga kakozwe mumashanyarazi ya polycrystalline guhera kumpera yo hepfo. Muri icyo gihe, ishoka yo hejuru no hepfo irazunguruka ikamanuka, ku buryo akarere gashonga kashizwemo kristu imwe.

Ibyiza bya zone gushonga itanura imwe ya kirisiti ni uko idashobora gusa kunoza ubuziranenge bwa kristu imwe yateguwe, ahubwo inatuma imikurire ya doping ikura neza, kandi inkoni imwe ya kirisiti irashobora kwezwa binyuze mubikorwa byinshi.

Ibibi bya zone gushonga itanura imwe ya kirisiti nigiciro kinini hamwe na diameter ntoya ya kristu imwe yateguwe. Kugeza ubu, diameter ntarengwa ya kristu imwe ishobora gutegurwa ni 200mm.

Uburebure muri rusange bwa zone bushonga ibikoresho byo mu itanura rya kirisiti imwe ni ndende cyane, kandi inkoni yo hejuru yo hepfo no hepfo ni ndende, bityo hashobora gukura inkoni ndende ya kirisiti.

3. Gutunganya ibikoresho bya Wafer

Inkoni ya kristu igomba kunyura murukurikirane rwibikorwa kugirango ikore insimburangingo ya silicon yujuje ibisabwa ninganda zikoreshwa na semiconductor, aribyo wafer. Inzira y'ibanze yo gutunganya ni:

Kunyerera, gukata, gukata, wafer annealing, gutondagura, gusya, gusya, gusukura no gupakira, nibindi.

3.1 Wafer Annealing

Mubikorwa byo gukora silikoni polycrystalline na silikoni ya Czochralski, silikoni imwe ya kirisiti irimo ogisijeni. Ku bushyuhe runaka, ogisijeni iri muri silikoni imwe ya kirisiti izatanga electron, na ogisijeni izahinduka abaterankunga ba ogisijeni. Izi electrone zizahuza hamwe numwanda muri wafer ya silicon kandi bigire ingaruka kumurwanya wa silicon.

Itanura rya Annealing: bivuga itanura rizamura ubushyuhe mu itanura kugeza kuri 1000-1200 ° C muri hydrogène cyangwa argon. Mugukomeza gushyuha no gukonjesha, ogisijeni hafi yubuso bwa wafer ya silicon isennye ihindagurika kandi igakurwa hejuru yacyo, bigatuma ogisijeni igwa kandi igatera.

Ibikoresho bitunganya bishonga inenge ya micro hejuru yubuso bwa silicon, bigabanya ubwinshi bwumwanda hafi yubuso bwa silikoni, kugabanya inenge, no gukora ahantu hasukuye cyane hejuru yubutaka bwa silikoni.

Itanura rya annealing ryitwa kandi itanura ryubushyuhe bwo hejuru kubera ubushyuhe bwaryo bwinshi. Inganda zita kandi silicon wafer annealing inzira igenda.

Silicon wafer annealing itanura igabanijwemo:

-Itanura rya anizingi;

-Itanura rifatika;

-Itanura ryuzuye.

Itandukaniro nyamukuru hagati yitanura rya horizontal hamwe nitanura rya vertical annealing itanura nicyerekezo cyicyumba cya reaction.

Icyumba cya reaction ya itanura itambitse itunganijwe itunganijwe neza, kandi igice cya waferi ya silicon kirashobora kwinjizwa mubyumba byerekana reaction y’itanura rya annealing icyarimwe. Igihe cya annealing mubisanzwe ni iminota 20 kugeza 30, ariko urugereko rwa reaction rukenera igihe kinini cyo gushyuha kugirango rugere kubushyuhe busabwa na annealing.

Inzira y'itanura rya vertical annealing nayo ikoresha uburyo bwo icyarimwe gupakira icyarimwe icyuma cya silikoni mucyumba cya reaction cya feri ya annealing kugirango ivurwe. Icyumba cya reaction gifite imiterere ihagaritse, ituma wafer ya silicon ishyirwa mubwato bwa quartz muburyo butambitse.

Muri icyo gihe, kubera ko ubwato bwa quartz bushobora kuzunguruka muri rusange mucyumba cyitwaramo, ubushyuhe bwa annealing bwicyumba cya reaction burasa, ikwirakwizwa ryubushyuhe kuri wafer ya silicon irasa, kandi ifite ibintu byiza biranga annealing. Nyamara, ikiguzi cyibikorwa bya feri ya vertical annealing itanura iruta iy'itanura rya horizontal.

Itanura ryihuta ryifashisha itara rya halogen tungsten kugirango rishyushye mu buryo butaziguye wafer ya silicon, ishobora kugera ku bushyuhe bwihuse cyangwa gukonja mu ntera ya 1 kugeza 250 ° C / s. Igipimo cyo gushyushya cyangwa gukonjesha kirihuta kuruta itanura gakondo. Bifata amasegonda make kugirango ushushe ubushyuhe bwa chambre hejuru ya 1100 ° C.

——————————————————————————————————————— ——

Semicera irashobora gutangaibice bya grafite,byoroshye / bikomeye,silicon karbide ibice, CVD silicon karbide ibice, naIbice bya SiC / TaChamwe na semiconductor yuzuye muminsi 30.

Niba ushimishijwe n'ibicuruzwa byavuzwe haruguru, nyamuneka ntutindiganye kutwandikira ubwambere.

Tel: + 86-13373889683

WhatsAPP: + 86-15957878134

Email: sales01@semi-cera.com

Igihe cyo kohereza: Kanama-26-2024