Mubikorwa byose bigira uruhare mukurema chip, iherezo ryanyuma ryawaferni ukugabanywa kumuntu kugipfa no gupakirwa mumasanduku mato, afunze udusanduku duke gusa. Chip izasuzumwa hashingiwe ku mbibi zayo, irwanya, iy'ubu, na voltage, ariko ntamuntu numwe uzirikana isura yayo. Mugihe cyo gukora, dusubiramo inshuro nyinshi wafer kugirango tugere kuri planarisation ikenewe, cyane cyane kuri buri ntambwe yo gufotora. UwitekawaferUbuso bugomba kuba buringaniye cyane kuko, uko inzira yo gukora chip igabanuka, lens ya mashini ya Photolithography ikenera kugera kuri nanometero-nini yo gukemura yongera ubwinshi bwimibare (NA) ya lens. Ariko, ibi icyarimwe bigabanya ubujyakuzimu bwibanze (DoF). Ubujyakuzimu bwibanze bwibanze ku burebure sisitemu optique ishobora gukomeza kwibandaho. Kugirango umenye neza ko ifoto ya Photolithographe iguma isobanutse kandi yibanze, ubuso butandukanye bwawaferigomba kugwa mubwimbitse bwibandwaho.

Mumagambo yoroshye, imashini ya Photolithography itanga ibitambo byibanda kubushobozi bwo kunoza amashusho neza. Kurugero, ibisekuru bishya bya EUV Photolithography imashini zifite numero ya 0.55, ariko ubujyakuzimu bwa vertical yibandaho ni nanometero 45 gusa, hamwe na ntoya ntoya yerekana amashusho mugihe cyo gufotora. Nibawaferntabwo iringaniye, ifite umubyimba utaringaniye, cyangwa hejuru yubutaka, bizatera ibibazo mugihe cya fotolitografiya murwego rwo hejuru kandi ruto.

Photolithography ntabwo aribwo buryo bwonyine busaba kugenda nezawaferhejuru. Ibindi bikorwa byinshi byo gukora chip nabyo bisaba poli ya wafer. Kurugero, nyuma yo gutonyanga neza, polishinge irakenewe kugirango horoherezwe ubuso bubi kugirango bitwikwe hanyuma bikabikwa. Nyuma yo gutandukanya umwobo muto (STI), birasabwa gusya kugirango dioxyde de silikoni irenze kandi yuzuze umwobo. Nyuma yo gushira ibyuma, polishinge irakenewe kugirango ikureho ibyuma birenze urugero kandi wirinde ibikoresho bigufi.

Kubwibyo, kuvuka kwa chip birimo intambwe nyinshi zo gusya kugirango ugabanye ubukana bwa wafer nuburyo butandukanye ndetse no kuvanaho ibintu birenze hejuru. Byongeye kandi, ubusembwa bwubuso buterwa nibibazo bitandukanye byerekeranye na wafer akenshi bigaragara gusa nyuma ya buri ntambwe. Rero, ba injeniyeri bashinzwe guswera bafite inshingano zikomeye. Nibibare nyamukuru mubikorwa byo gukora chip kandi akenshi bafite amakosa mumanama yumusaruro. Bagomba kuba abahanga muburyo bwo gutobora no gusohora kumubiri, nkubuhanga nyamukuru bwo gusya mu gukora chip.

Nubuhe buryo bwo gusiga wafer?

Inzira yo gusya irashobora gushyirwa mubyiciro bitatu byingenzi bishingiye kumahame yimikoranire hagati yamazi ya polishinge na silicon wafer:

1. Uburyo bwo gukanika imashini:

Gukoresha imashini ikuraho ubuso busa neza binyuze mu gukata no guhindura plastike kugirango ugere ku buso bunoze. Ibikoresho bisanzwe birimo amabuye ya peteroli, ibiziga by'ubwoya, hamwe na sandpaper, cyane cyane bikorwa n'intoki. Ibice bidasanzwe, nkubuso bwimibiri izunguruka, birashobora gukoresha ibintu bihinduka nibindi bikoresho bifasha. Ku buso bufite ibisabwa byujuje ubuziranenge, uburyo bwiza bwo gusya burashobora gukoreshwa. Amashanyarazi meza cyane akoresha ibikoresho byabigenewe byabigenewe, ibyo, mumazi arimo ibishishwa birimo ibishishwa, bikanda cyane hejuru yumurimo wakazi kandi bikazunguruka ku muvuduko mwinshi. Ubu buhanga bushobora kugera ku buso bwa Ra0.008μm, hejuru cyane muburyo bwose bwo gusya. Ubu buryo bukunze gukoreshwa muburyo bwa optique.

2. Uburyo bwo gutunganya imiti:

Imiti ya chimique ikubiyemo gushonga kwa micro-protrusi hejuru yibintu muburyo bwa chimique, bikavamo ubuso bunoze. Ibyiza byingenzi byubu buryo ni ukudakenera ibikoresho bigoye, ubushobozi bwo gutonesha ibihangano bimeze nkibikorwa, hamwe nubushobozi bwo gutonesha ibihangano byinshi icyarimwe hamwe nubushobozi buhanitse. Ikibazo nyamukuru cyo gusya imiti nugukora amavuta yo kwisiga. Ubuso bwubuso bugerwaho no gusya imiti mubisanzwe ni micrometero mirongo.

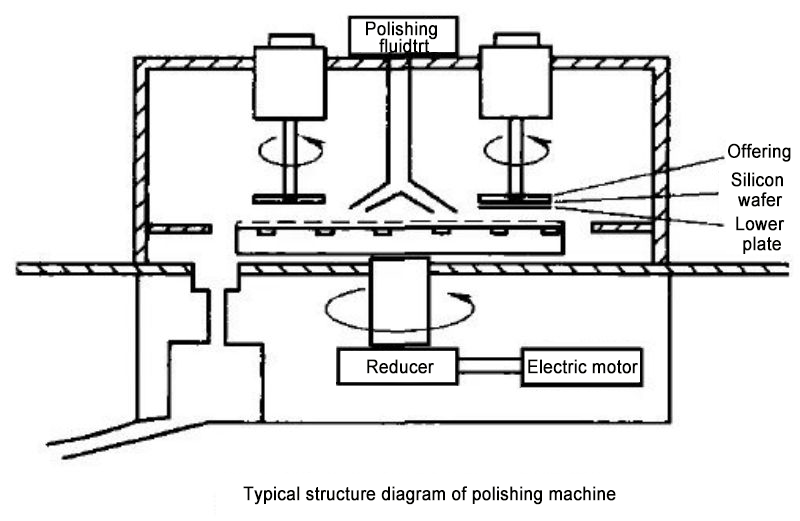

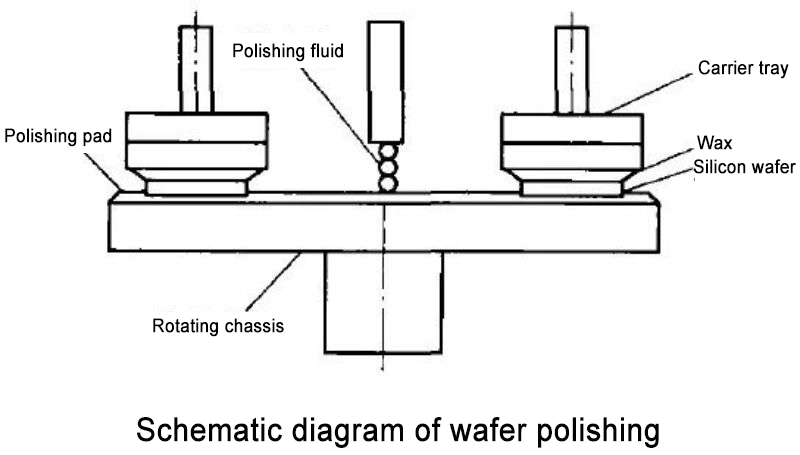

3. Uburyo bwa mashini yimashini (CMP) Uburyo:

Bumwe muburyo bubiri bwa mbere bwo gusya bufite ibyiza byihariye. Guhuza ubu buryo bubiri birashobora kugera ku ngaruka zuzuzanya mubikorwa. Imashini yimashini ikomatanya guhuza imashini hamwe nuburyo bwo kwangirika. Mugihe cya CMP, imiti igabanya ubukana bwa okiside ya okiside yibikoresho bya substrate isukuye, bigakora urwego rworoshye rwa oxyde. Iyi oxyde ya oxyde noneho ikurwaho binyuze mumashanyarazi. Gusubiramo iyi okiside hamwe no gukuraho imashini bigera kuri polishinge nziza.

Inzitizi n'ibibazo biriho muri mashini ya mashini ya mashini (CMP):

CMP ihura nibibazo byinshi mubibazo byikoranabuhanga, ubukungu, no kubungabunga ibidukikije:

1) Guhuza inzira: Kugera kumurongo mwinshi mubikorwa bya CMP bikomeje kuba ingorabahizi. Ndetse no mumurongo umwe wumusaruro, itandukaniro rito muburyo bwimikorere hagati yibice bitandukanye cyangwa ibikoresho birashobora kugira ingaruka kubicuruzwa byanyuma.

2) Guhuza Ibikoresho bishya: Mugihe ibikoresho bishya bikomeje kugaragara, tekinoroji ya CMP igomba guhuza nibiranga. Bimwe mubikoresho byateye imbere ntibishobora guhuzwa nibikorwa gakondo bya CMP, bisaba ko habaho iterambere ryimyororokere myinshi ihindagurika.

3) Ingano Ingano: Mugihe ibipimo byigikoresho cya semiconductor bikomeje kugabanuka, ibibazo biterwa ningaruka zingana biba ngombwa. Ibipimo bito bisaba uburinganire buringaniye, bisaba inzira za CMP zisobanutse neza.

4) Igipimo cyo Gukuraho Igikoresho: Mubisabwa bimwe, kugenzura neza igipimo cyo gukuraho ibikoresho kubikoresho bitandukanye ni ngombwa. Kugenzura igipimo gihoraho cyo gukuraho mubice bitandukanye mugihe CMP ningirakamaro mugukora ibikoresho bikora neza.

5) Ibidukikije byangiza ibidukikije: Amavuta yo kwisiga hamwe na abrasives zikoreshwa muri CMP zishobora kuba zirimo ibintu byangiza ibidukikije. Ubushakashatsi niterambere ryibidukikije byangiza ibidukikije kandi birambye CMP nibikorwa nibikoresho byingenzi.

6) Ubwenge na Automation: Mugihe urwego rwubwenge na automatike ya sisitemu ya CMP igenda itera imbere buhoro buhoro, bagomba gukomeza guhangana n’ibidukikije bigoye kandi bihinduka. Kugera ku nzego zo hejuru zo gukoresha no kugenzura ubwenge kugirango tunoze umusaruro ni ikibazo gikwiye gukemurwa.

7) Igenzura ry'ibiciro: CMP ikubiyemo ibikoresho bihanitse n'ibiciro by'ibikoresho. Ababikora bakeneye kunoza imikorere mugihe baharanira kugabanya ibiciro byumusaruro kugirango bakomeze guhangana kumasoko.

Igihe cyo kohereza: Jun-05-2024