Niki Silicon Carbide SiC Coating?

Ipitingi ya Silicon Carbide (SiC) nubuhanga bwimpinduramatwara butanga uburinzi budasanzwe nubushuhe budasanzwe mubushyuhe bwo hejuru hamwe na chimique ibidukikije. Ipitingi yateye imbere ikoreshwa mubikoresho bitandukanye, birimo grafite, ububumbyi, nicyuma, kugirango byongere imitungo yabyo, bitanga uburinzi bukomeye bwo kwirinda ruswa, okiside, no kwambara. Imiterere yihariye yimyenda ya SiC, harimo ubuziranenge bwayo, ubwiza bwumuriro mwiza, hamwe nuburinganire bwimiterere, bituma biba byiza gukoreshwa mubikorwa nkinganda zikora imashanyarazi, icyogajuru, hamwe nikoranabuhanga rishyushya cyane.

Ibyiza bya silicon karbide

Igicapo cya SiC gitanga inyungu nyinshi zingenzi zitandukanya imyenda gakondo irinda:

- -Ubucucike Bwinshi & Kurwanya Ruswa

- Imiterere ya cubic SiC itanga ubwuzuzanye bwinshi, igateza imbere cyane kurwanya ruswa kandi ikongerera igihe ubuzima.

- -Gupfukirana bidasanzwe byimiterere igoye

- Ipfunyika rya SiC rizwiho gukwirakwiza neza, ndetse no mu mwobo muto uhumye ufite ubujyakuzimu bugera kuri mm 5, utanga umubyimba umwe kugeza kuri 30% ahantu harehare.

- -Ubuso bushobora kugaragara

- Igikorwa cyo gutwikira kirahinduka, cyemerera ubuso butandukanye kugirango bushobore gusaba ibisabwa.

- -Icyuma kinini

- Byagezweho hifashishijwe ikoreshwa rya gaze zifite isuku nyinshi, igicapo cya SiC gikomeza kuba cyiza cyane, hamwe n’umwanda mubisanzwe munsi ya 5 ppm. Uku kweza ningirakamaro mubikorwa byubuhanga buhanitse bisaba ubuziranenge kandi bwanduye cyane.

- -Ubushyuhe bwumuriro

- Silicon karbide ceramic ceramic irashobora kwihanganira ubushyuhe bukabije, hamwe nubushyuhe ntarengwa bwo gukora bugera kuri 1600 ° C, bigatuma ubwizerwe bwibidukikije biri hejuru.

Porogaramu ya SiC

Ibikoresho bya SiC bikoreshwa cyane mubikorwa bitandukanye kubikorwa byabo bitagereranywa mubidukikije bigoye. Ibyingenzi byingenzi birimo:

- -LED & Solar Inganda

- Ipitingi ikoreshwa kandi mubice bigize LED nizuba ryizuba, aho usanga ari ngombwa cyane.

- -Ikoranabuhanga rishyushye cyane

- SiC ikozweho na grafite nibindi bikoresho bikoreshwa mubushuhe bwamashyiga hamwe na reakteri zikoreshwa mubikorwa bitandukanye byinganda.

- -Imikurire ya Crystal

- Mu mikurire ya semiconductor, kristu ya SiC ikoreshwa mukurinda ibice bigira uruhare mu mikurire ya silicon hamwe nandi ma kristu ya semiconductor, bitanga imbaraga zo kurwanya ruswa hamwe nubushyuhe bwumuriro.

- -Silicon na SiC Epitaxy

- Ibikoresho bya SiC bikoreshwa mubice bigize gahunda yo gukura kwa epitaxial ya silicon na karbide ya silicon (SiC). Iyi myenda irinda okiside, kwanduza, kandi ikemeza ubwiza bwibice bya epitaxial, ari ingenzi cyane mu gukora ibikoresho bya semiconductor bikora neza.

- -Oxidation na Diffusion Inzira

- Ibikoresho bya SiC bikoreshwa muburyo bwa okiside no gukwirakwiza, aho bitanga inzitizi nziza yo kurwanya umwanda udashaka kandi bikazamura ubusugire bwibicuruzwa byanyuma. Ipitingi itezimbere kuramba no kwizerwa byibice byerekanwe nubushyuhe bwo hejuru bwa okiside cyangwa intambwe yo gukwirakwizwa.

Ibyingenzi byingenzi bya CoC

Ibicuruzwa bya SiC bitanga urutonde rwimitungo izamura imikorere nigihe kirekire cyibikoresho bisize:

- -Imiterere ya Kirisitu

- Ipitingi ikorwa hamwe na aβ 3C (cubic) kristuimiterere, ni isotropic kandi itanga uburyo bwiza bwo kurinda ruswa.

- -Ubucucike n'ubwinshi

- Ibikoresho bya SiC bifite ubucucike bwa3200 kg / m³no kwerekana0%, kwemeza imikorere ya helium ikora neza no kurwanya ruswa.

- -Ubushyuhe bwamashanyarazi

- Igicapo cya SiC gifite ubushyuhe bwinshi(200 W / m · K)n'amashanyarazi meza cyane(1MΩ · m), gukora nibyiza kubisabwa bisaba gucunga ubushyuhe no gukwirakwiza amashanyarazi.

- -Imbaraga za mashini

- Hamwe na moderi ya elastike ya450 GPa, Ipitingi ya SiC itanga imbaraga zumukanishi, zizamura uburinganire bwimiterere yibigize.

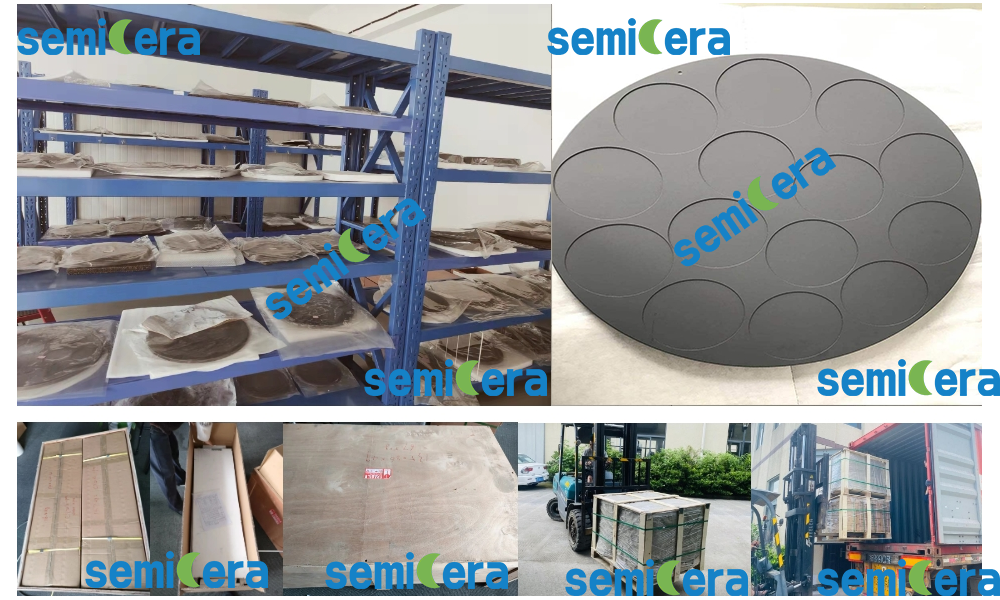

SiC silicon karbide itwikiriye

Igicapo cya SiC gikoreshwa binyuze muri Chemical Vapor Deposition (CVD), inzira ikubiyemo kubora ubushyuhe bwa gaze kugirango ubike ibice bito bya SiC kuri substrate. Ubu buryo bwo kubitsa butuma umuvuduko wubwiyongere bukabije no kugenzura neza kubyimbye, bishobora kuva10 µm kugeza 500 µm, Bitewe na Porogaramu. Igikorwa cyo gutwikira kandi gitanga ubwuzuzanye bumwe, ndetse no muri geometrike igoye nk'imyobo mito cyangwa yimbitse, ubusanzwe bikaba bigoye kuburyo bwa gakondo.

Ibikoresho bikwiranye na SiC

Ibikoresho bya SiC birashobora gukoreshwa mubikoresho byinshi, harimo:

- -Graphite na Carbone Ibigize

- Graphite ni substrate izwi cyane kubutaka bwa SiC kubera ubwiza bwumuriro n amashanyarazi. Igicapo cya SiC cyinjira mubishushanyo mbonera bya grafite, bigakora umurongo wongerewe kandi ugatanga uburinzi buhebuje.

- -Ubutaka

- Ubukorikori bushingiye kuri silikoni nka SiC, SiSiC, na RSiC bungukirwa n’imyenda ya SiC, iteza imbere kwangirika kwabo no kwirinda ikwirakwizwa ry’imyanda.

Kuki Guhitamo SiC?

Ubuso bwo hejuru butanga igisubizo cyinshi kandi cyigiciro cyinganda zisaba isuku ryinshi, kurwanya ruswa, hamwe nubushyuhe bwumuriro. Waba ukora muri semiconductor, icyogajuru, cyangwa amashanyarazi ashyushye cyane, impuzu za SiC zitanga uburinzi nibikorwa ukeneye kugirango ukomeze kuba indashyikirwa mubikorwa. Ihuriro ryubucucike bwububiko bwinshi, imiterere yubuso bwihariye, hamwe nubushobozi bwo gutwikisha geometrike yemeza ko sic coated element ishobora kwihanganira nibidukikije bigoye cyane.

Kubindi bisobanuro cyangwa kuganira uburyo silicon karbide ceramic coating ishobora kugirira akamaro porogaramu yawe, nyamunekatwandikire.

Igihe cyo kohereza: Kanama-12-2024