Ubwato bwa SiC Wafer

Silicon carbide wafer ubwatoni igikoresho cyikorera imitwaro kuri wafers, gikoreshwa cyane muburyo bwo gukwirakwiza izuba na semiconductor. Ifite ibiranga nko kurwanya kwambara, kurwanya ruswa, kurwanya ubushyuhe bwo hejuru, kurwanya ibisasu bya plasma, ubushobozi bwo gutwara ubushyuhe bwinshi, gutwara ubushyuhe bwinshi, gukwirakwiza ubushyuhe bwinshi, no gukoresha igihe kirekire bitari byoroshye kunama no guhindura. Isosiyete yacu ikoresha ibikoresho byinshi bya silicon karbide kugirango ibone ubuzima bwa serivisi kandi itanga ibishushanyo byabigenewe, harimo. vertical na horizontalubwato bwa wafer.

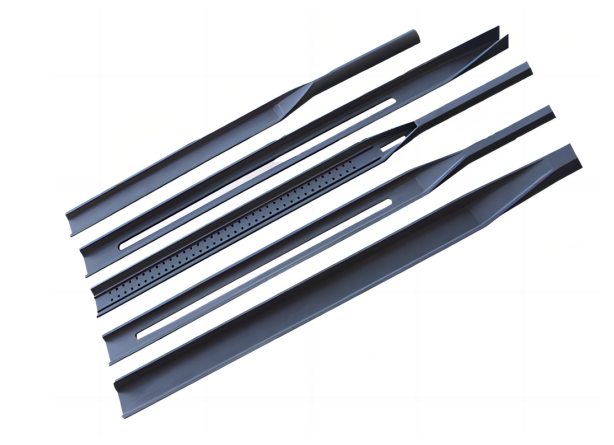

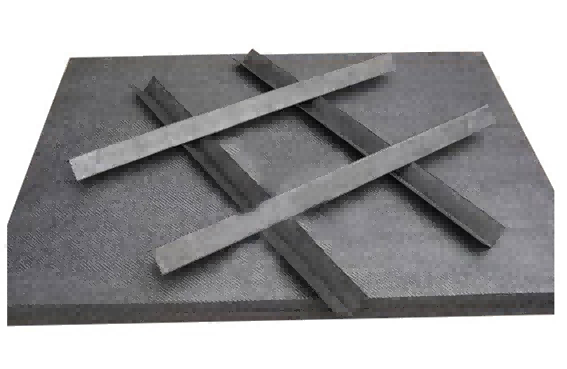

SiC Paddle

Uwitekasilicon carbide cantilever paddleikoreshwa cyane cyane mu gukwirakwiza (diffuzione) ya wafer ya silicon, igira uruhare runini mu gupakira no gutwara wafer ya silicon ku bushyuhe bwinshi. Nibintu byingenzi bigizesemiconductor wafersisitemu yo gupakira kandi ifite ibintu nyamukuru bikurikira:

1. Ntabwo ihindagurika mubushyuhe bwo hejuru kandi ifite imbaraga nyinshi zo gupakira kuri wafers;

2. Irwanya ubukonje bukabije nubushyuhe bwihuse, kandi ifite ubuzima burebure;

3. Coefficient yo kwagura ubushyuhe ni nto, yagura cyane uburyo bwo kubungabunga no gukora isuku, kandi igabanya cyane umwanda.

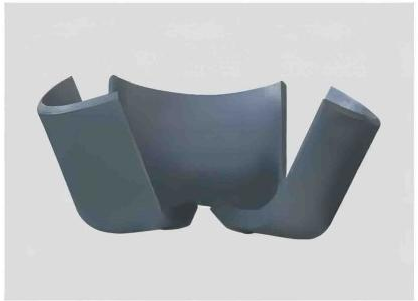

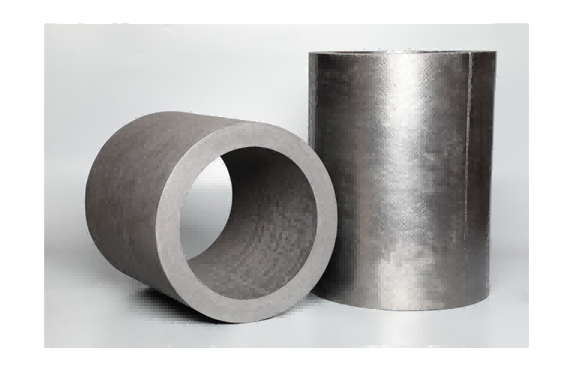

SiC Furnace Tube

Silicon carbide process tube, bikozwe muri SiC-isukuye cyane idafite umwanda wibyuma, ntabwo ihumanya wafer, kandi irakwiriye mubikorwa nka semiconductor na fotokolta ikwirakwizwa, annealing na okiside.

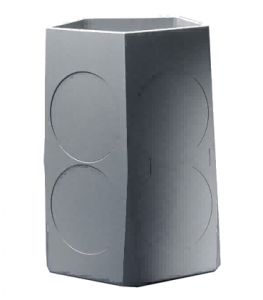

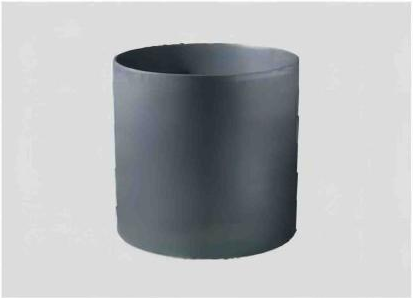

Imashini ya Robo

Imashini ya robot, bizwi kandi nka wafer ihererekanyabubasha, ni ukuboko kwa robo ikoreshwa mu gutwara waferi ya semiconductor kandi ikoreshwa cyane mu nganda zikoresha ingufu za semiconductor, optoelectronic, n’izuba. Gukoresha karbide nziza cyane ya silicon, hamwe nuburemere bukabije, kwambara birwanya, kurwanya imitingito, gukoresha igihe kirekire nta guhindura ibintu, ubuzima bumara igihe kirekire, nibindi, birashobora gutanga serivisi zihariye.

Igishushanyo cyo gukura kwa kirisiti

Graphite ingabo

Graphite electrode

Igishushanyo mbonera

Graphite chuck

Inzira zose zikoreshwa mukuzamura semiconductor crvstals zikorera mubushyuhe bwo hejuru kandi bwangirika. Agace gashyushye k'itanura rikura rya kirisiti mubusanzwe usanga ryuzuyemo ubushyuhe kandi butarwanya ruswa. ibice bya grafite, nkubushyuhe bwa grafite, umusaraba, silinderi, deflector, chucks, tubes, impeta, abafite, nuts, etcl Ibicuruzwa byacu byarangiye birashobora kugera kumivu iri munsi ya 5ppm.

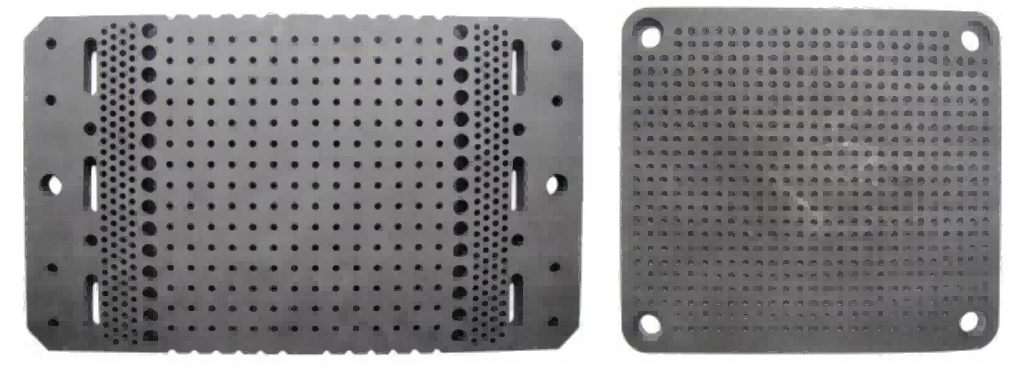

Igishushanyo cya Semidonductor Epitaxy

MOCVD Ibice bishushanyo

Semiconductor Graphite Ibikoresho

Epitaxial inzira yerekana imikurire yikintu kimwe cya kirisiti kumurongo umwe wa kirisiti hamwe na lattice itunganijwe kimwe na substrate. Irasaba ibice byinshi bya ultra-high isuku ibice bya grafite hamwe na grafite base hamwe na SIC. Igicapo kinini cyera cyakoreshejwe kuri semiconductor epitaxy gifite uburyo bwinshi bwa porogaramu, zishobora guhuza ibikoresho bikoreshwa cyane mu nganda, Mugihe kimwe, gifite hejuru cyane. ubuziranenge, gutwikira kimwe, ubuzima bwiza bwa serivisi, hamwe nubushakashatsi bukabije bwimiti hamwe nubushyuhe bwumuriro.

Ibikoresho byo gukumira nibindi

Ibikoresho byo kubika amashyuza bikoreshwa mu musaruro wa semiconductor ni grafitike ikomeye, yoroheje, ibyuma bya grafite, ibikoresho bya karubone, n'ibindi. yose. Ibikoresho bya karubone bikoreshwa muburyo bwo gutwara imirasire y'izuba hamwe na polysilicon.