Amashanyarazi ya Semiconductor afite umwanya wingenzi muri sisitemu ya elegitoroniki y’amashanyarazi, cyane cyane mu rwego rwo guteza imbere byihuse ikoranabuhanga nk’ubwenge bw’ubukorikori, itumanaho rya 5G n’imodoka nshya z’ingufu, ibisabwa kugira ngo bikore neza.

Carbide. Nyamara, 4H-SiC ifite ubukana bwinshi, ubukana bwinshi, kutagira imiti ikomeye, hamwe ningorabahizi yo gutunganya. Ubuso bwubuso bwa substrate wafer ningirakamaro kubikoresho binini binini.

Kubwibyo, kuzamura ubwiza bwubuso bwa 4H-SiC substrate wafer, cyane cyane kuvanaho ibyangiritse hejuru yubutaka bwo gutunganya wafer, nurufunguzo rwo kugera kubikorwa byiza, bitakaza igihombo kandi byujuje ubuziranenge bwa 4H-SiC.

Ubushakashatsi

Ubushakashatsi bukoresha ingero ya 4-N-ubwoko bwa 4H-SiC ingot ikura nuburyo bwo gutwara imyuka yumubiri, itunganywa hakoreshejwe guca insinga, gusya, gusya bikabije, gusya neza no gusya, kandi byandika uburebure bwakuweho hejuru ya C n'ubuso bwa Si n'ubunini bwa nyuma bwa wafer muri buri gikorwa.

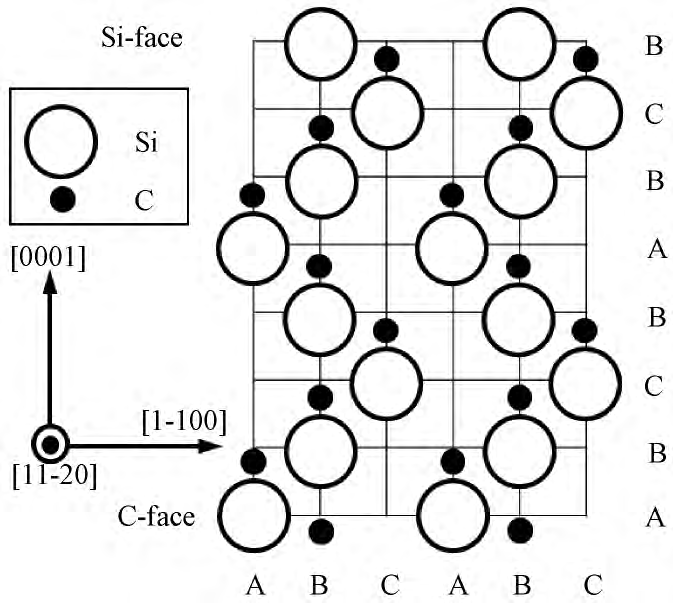

Igishushanyo 1 Igishushanyo mbonera cya 4H-SiC imiterere ya kristu

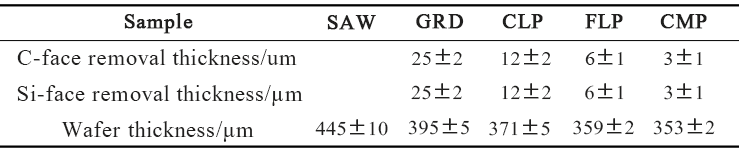

Igishushanyo 2 Ubunini bwakuwe kuri C-kuruhande na Si-uruhande rwa 4H-SiC wafernyuma yintambwe zitandukanye zo gutunganya nubunini bwa wafer nyuma yo gutunganywa

Umubyimba, morfologiya yubuso, ubukana hamwe nubukanishi bwa wafer byaranzwe byuzuye na testteri ya wafer ya geometriyeri, microscope itandukanya itandukaniro, microscope yingufu za atome, ibikoresho bipima uburemere bwa nanoindenter. Mubyongeyeho, imiterere-y-X-ray diffractometer yakoreshejwe kugirango isuzume ubuziranenge bwa wafer.

Izi ntambwe zigeragezwa hamwe nuburyo bwikizamini zitanga ubufasha burambuye bwa tekiniki yo kwiga igipimo cyo gukuraho ibintu hamwe nubuziranenge bwubutaka mugihe cyo gutunganya 4H-Wafers.

Binyuze mu bushakashatsi, abashakashatsi basesenguye impinduka zijyanye no gukuraho ibintu (MRR), imiterere y’imiterere n’ubukonje, hamwe n’imiterere yubukanishi hamwe n’ubuziranenge bwa 4H-Wafersmuburyo butandukanye bwo gutunganya (gukata insinga, gusya, gusya bikabije, gusya neza, gusya).

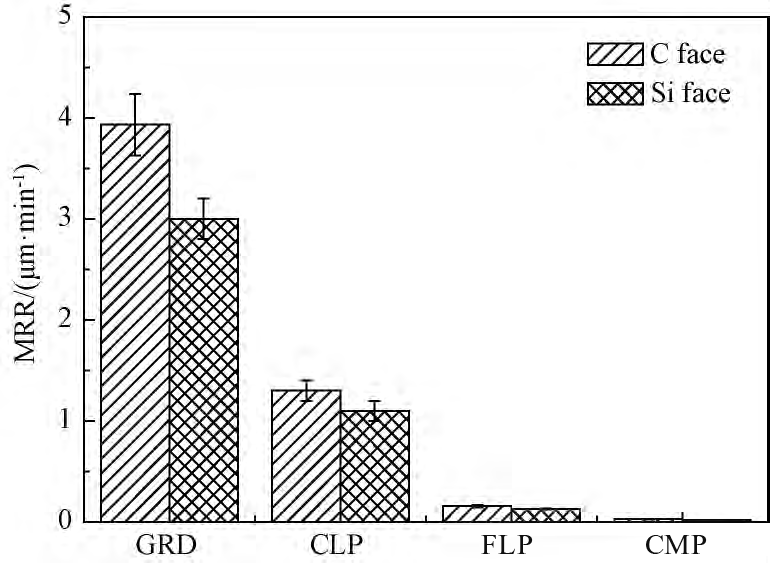

Igishushanyo cya 3 Igipimo cyo gukuraho ibikoresho bya C-isura na Si-isura ya 4H-SiC wafermu ntambwe zitandukanye zo gutunganya

Ubushakashatsi bwerekanye ko kubera anisotropy yimiterere yimiterere yimiterere itandukanye ya 4H-SiC, hariho itandukaniro muri MRR hagati ya C-face na Si-face muburyo bumwe, kandi MRR ya C-face iri hejuru cyane ugereranije iya Si-face. Hamwe niterambere ryintambwe yo gutunganya, hejuru ya morphologie hamwe nubusembwa bwa 4H-SiC wafers bigenda byoroha. Nyuma yo gusya, Ra ya C-isura ni 0,24nm, naho Ra ya Si-face igera kuri 0.14nm, ishobora guhaza ibikenewe byo gukura epitaxial.

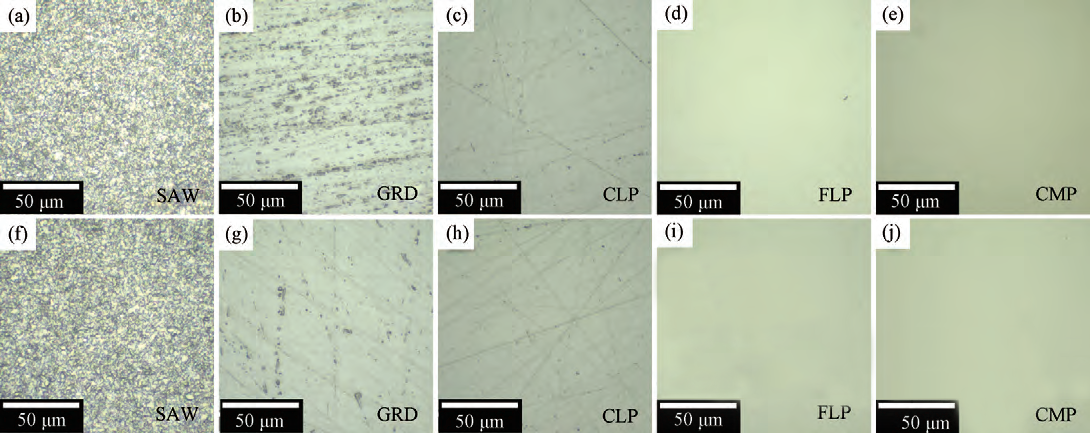

Igicapo 4 Amashusho meza ya microscope yubuso bwa C (a ~ e) na Si hejuru (f ~ j) ya wafer ya 4H-SiC nyuma yintambwe zitandukanye zo gutunganya

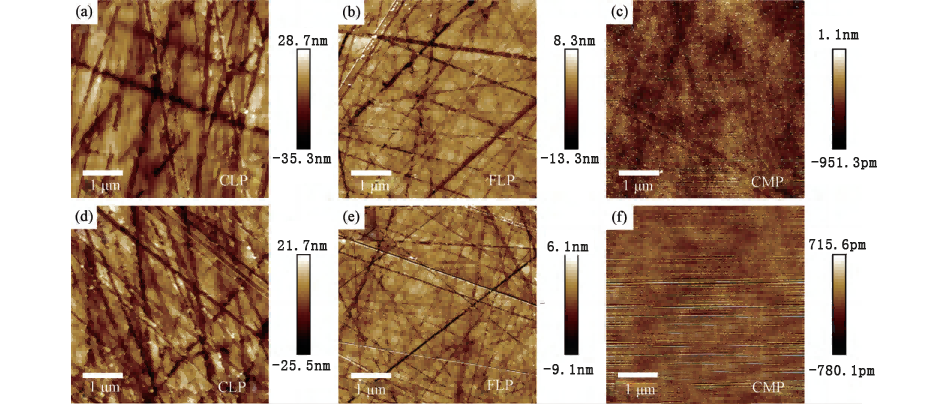

Igicapo 5 Imbaraga za Atome microscope ishusho yubuso bwa C (a ~ c) na Si hejuru (d ~ f) ya wafer ya 4H-SiC nyuma yintambwe yo gutunganya CLP, FLP na CMP

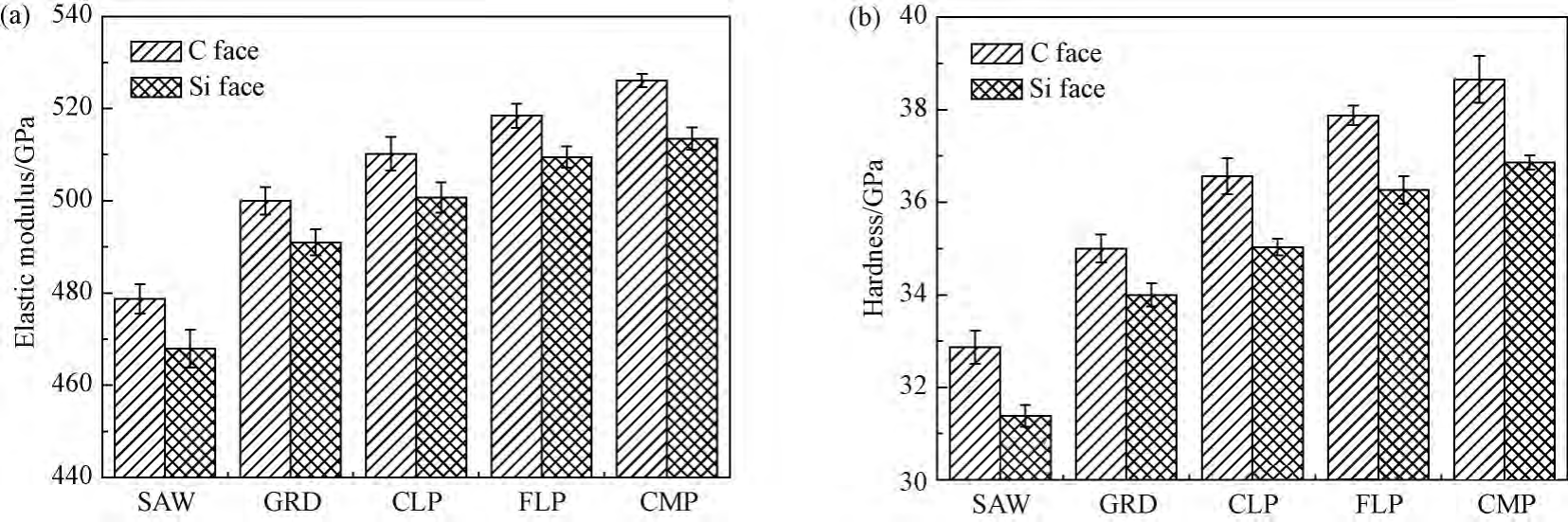

Igishushanyo cya 6 (a) modulus ya elastike na (b) ubukana bwubuso bwa C hamwe na Si hejuru ya 4H-SiC wafer nyuma yintambwe zitandukanye zo gutunganya

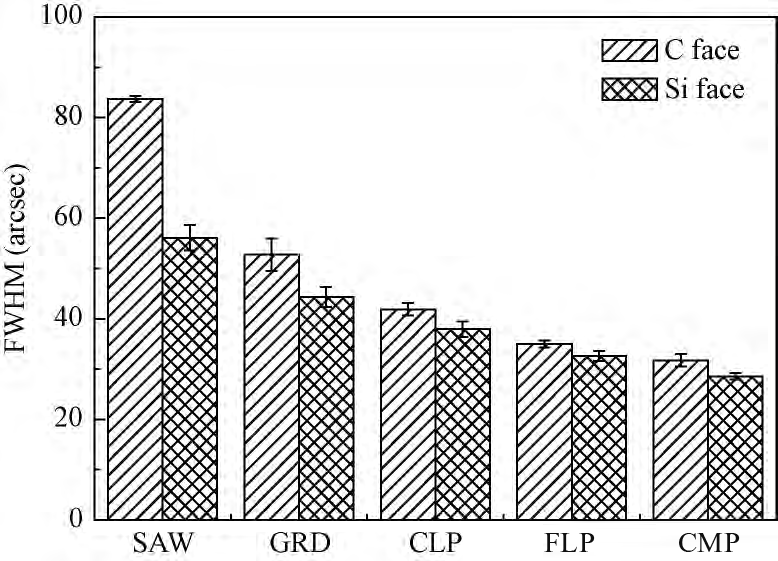

Ikizamini cyumutungo wa mashini cyerekana ko C hejuru ya wafer ifite ubukana bukabije kurenza ibikoresho byo hejuru ya Si, urwego runini rwo kuvunika kuvunika mugihe cyo gutunganya, kuvanaho ibintu byihuse, hamwe nubutaka bubi bwimiterere nuburiganya. Kuraho ibice byangiritse hejuru yuburyo butunganijwe nurufunguzo rwo kuzamura ubwiza bwubuso bwa wafer. Ubugari bwa kimwe cya kabiri cy'ubugari bwa 4H-SiC (0004) gutembagaza umurongo birashobora gukoreshwa mu buryo bwimbitse kandi neza kuranga no gusesengura ibyangiritse hejuru ya wafer.

Igicapo 7 (0004) kunyeganyega umurongo igice cyubugari bwa C-isura na Si-isura ya 4H-SiC wafer nyuma yintambwe zitandukanye zo gutunganya

Ibisubizo byubushakashatsi byerekana ko ibyangiritse byangiritse kuri wafer bishobora gukurwaho buhoro buhoro nyuma yo gutunganya wafer ya 4H-SiC, bigatezimbere neza ubwiza bwubuso bwa wafer kandi bigatanga tekiniki yubuhanga bwo gukora neza, gutakaza bike no gutunganya ubuziranenge ya 4H-SiC substrate wafers.

Abashakashatsi batunganije waferi ya 4H-SiC binyuze mu ntambwe zitandukanye zo gutunganya nko guca insinga, gusya, gusya bikabije, gusya neza no gusya, kandi biga ku ngaruka zibi bikorwa ku bwiza bwa wafer.

Ibisubizo byerekana ko hamwe niterambere ryintambwe yo gutunganya, hejuru ya morphologie hamwe nubukonje bwa wafer bigenda byoroha. Nyuma yo gusya, ubukana bwa C-isura na Si-face bugera kuri 0.24nm na 0.14nm, ibyo bikaba byujuje ibisabwa kugirango umuntu akure epitaxial. C-isura ya wafer ifite ubukana bubi kuruta ibikoresho bya Si-face, kandi ikunze kuvunika kuvunika mugihe cyo kuyitunganya, bikavamo imiterere mibi ya morfologiya no gukomera. Kuraho ibyangiritse hejuru yubutaka bwatunganijwe nurufunguzo rwo kuzamura ubwiza bwubuso bwa wafer. Igice cya kabiri cy'ubugari bwa 4H-SiC (0004) umurongo uhindagurika urashobora gushishoza kandi neza kuranga ibyangiritse hejuru ya wafer.

Ubushakashatsi bwerekana ko urwego rwangiritse hejuru yubuso bwa 4H-SiC rushobora gukurwaho buhoro buhoro binyuze mu gutunganya wafer ya 4H-SiC, bikazamura neza ubwiza bw’imiterere ya wafer, bigatanga tekiniki ya tekiniki yo gukora neza, gutakaza bike, no hejuru- gutunganya ubuziranenge bwa 4H-SiC substrate wafers.

Igihe cyo kohereza: Nyakanga-08-2024