Silicon nitride yahujwe na silicon karbide

Si3N4 ihujwe na SiC ceramic yamashanyarazi, ivangwa nifu nziza ya SIC nziza nifu ya Silicon, nyuma yamasomo yo guterera kunyerera, reaction yagabanutse munsi ya 1400 ~ 1500 ° C.Mugihe cyamasomo yo gucumura, kuzuza Azote nziza cyane mu itanura, noneho silicon izakorana na Nitrogen ikabyara Si3N4, So SiNN4 ibikoresho bya SiC bihujwe rero na nitride ya silicon (23%) na karubide ya silicon (75%) nkibikoresho nyamukuru , ivanze nibikoresho kama, kandi bigizwe nuruvange, gusohora cyangwa gusuka, hanyuma bikozwe nyuma yo gukama na azote.

Ibiranga ibyiza:

1.High kwihanganira ubushyuhe

2.Ubushyuhe bwo hejuru bwumuriro no kurwanya ihungabana

3.Imbaraga zumukanishi hamwe no kurwanya abrasion

4.Imbaraga nziza zingirakamaro no kurwanya ruswa

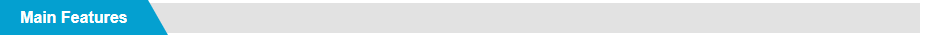

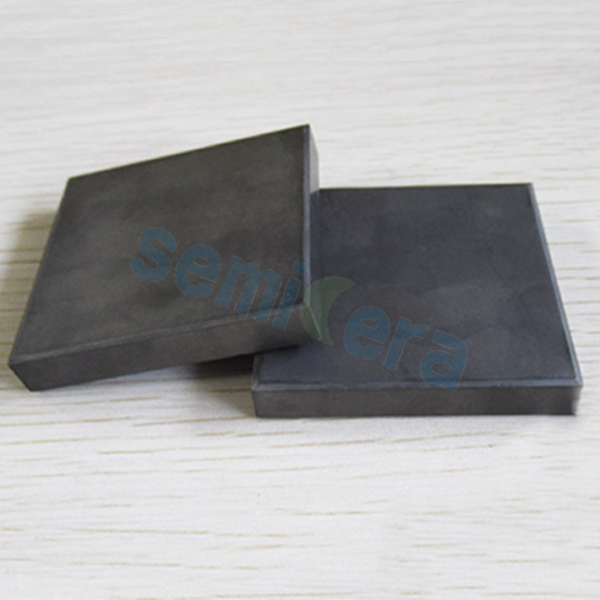

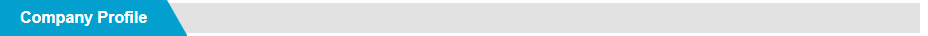

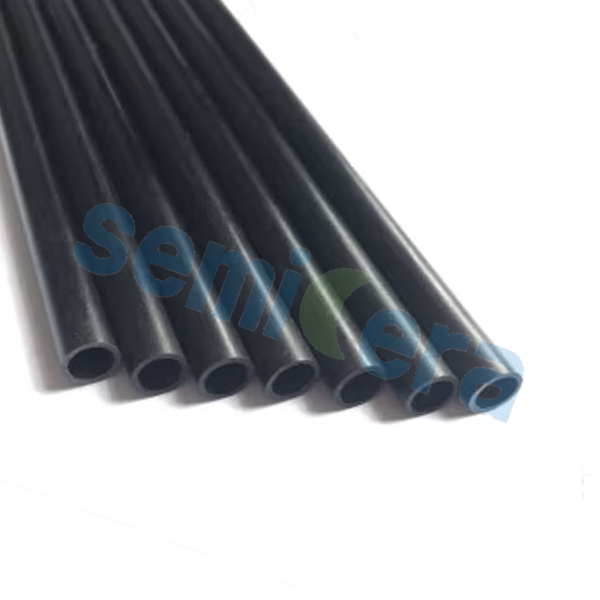

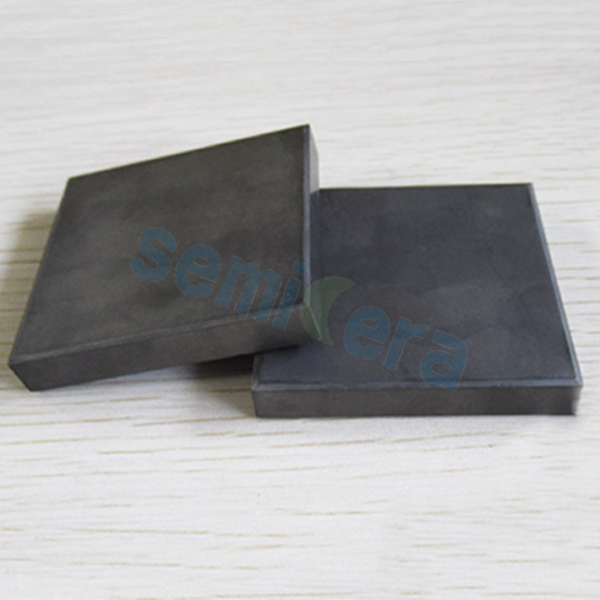

Dutanga ubuziranenge kandi bwuzuye bwakozwe na NSiC ceramic ibice bitunganywa na

1.Gucuranga

2.Gusoma

3.Uni Kanda

4.Gukanda

Urupapuro rwibikoresho

| > Ibigize imiti | Sic | 75% |

| Si3N4 | ≥23% | |

| Ubuntu Si | 0% | |

| Ubucucike bwinshi (g / cm3) | 2.70~2.80 | |

| Ikigaragara ni uko (%) | 12~15 | |

| Hindura imbaraga kuri 20 ℃ (MPa) | 180~190 | |

| Hindura imbaraga kuri 1200 ℃ (MPa) | 207 | |

| Hindura imbaraga kuri 1350 ℃ (MPa) | 210 | |

| Imbaraga zo kwikuramo kuri 20 ℃ (MPa) | 580 | |

| Ubushyuhe bwumuriro kuri 1200 ℃ (w / mk) | 19.6 | |

| Coefficient yo kwagura ubushyuhe kuri 1200 ℃ (x 10-6 /C) | 4.70 | |

| Kurwanya ubushyuhe | Cyiza | |

| Icyiza.ubushyuhe (℃) | 1600 | |

WeiTai Energy Technology Co., Ltd nisoko ritanga amasoko meza ya semiconductor ceramics kandi rukaba rukora uruganda rukumbi mu Bushinwa rushobora icyarimwe gutanga icyarimwe cyiza cya silicon karbide ceramic (cyane cyane Recrystallized SiC) hamwe na CVD SiC.Mubyongeyeho, isosiyete yacu yiyemeje kandi mumirima yubutaka nka alumina, nitride ya aluminium, zirconi, na nitride ya silicon, nibindi.

Ibicuruzwa byacu byingenzi birimo: silicon carbide etching disiki, ubwato bwa silicon karbide, ubwato bwa silicon karbide wafer (Photovoltaic & Semiconductor), itanura ya carbide itanura, silikoni karbide cantilever, amashanyarazi ya karuboni, hamwe na CVD SiC hamwe na TaC gutwikira.Ibicuruzwa bikoreshwa cyane cyane munganda za semiconductor ninganda zifotora, nkibikoresho byo gukura kristu, epitaxy, etching, gupakira, gutwikira no gutwika itanura, nibindi.

Isosiyete yacu ifite ibikoresho byuzuye byo kubyaza umusaruro nko kubumba, gucumura, gutunganya, ibikoresho byo gutwikira, nibindi, bishobora kuzuza amahuza yose akenewe yumusaruro wibicuruzwa kandi bikagenzurwa cyane nubwiza bwibicuruzwa;Gahunda nziza yumusaruro irashobora gutoranywa ukurikije ibikenerwa nibicuruzwa, bikavamo igiciro gito no guha abakiriya ibicuruzwa birushanwe;Turashobora gukora neza kandi neza gahunda yumusaruro dushingiye kubisabwa byo gutanga ibicuruzwa kandi dufatanije na sisitemu yo gucunga ibicuruzwa kumurongo, guha abakiriya igihe cyihuse kandi cyizewe.

-

Ubushyuhe bwo hejuru reaction sintering silicon imodoka ...

-

Koresha ubushyuhe bwo hejuru burwanya ubushyuhe bwa grafite

-

Icuma cya silicon karbide isahani idafite ...

-

Ubushyuhe bwo hejuru burwanya silicon karbide cera ...

-

Ingano zitandukanye za silicon karbide yashizeho irashobora ...

-

Semiconductor ceramic izingira impeta