Kugeza ubu, igisekuru cya gatatu cya semiconductor yiganjemosilicon karbide. Mu miterere yikiguzi cyibikoresho byayo, substrate ihwanye na 47%, naho epitaxy igera kuri 23%. Byombi hamwe bingana na 70%, nigice cyingenzi cyasilicon karbideUruganda rukora ibikoresho.

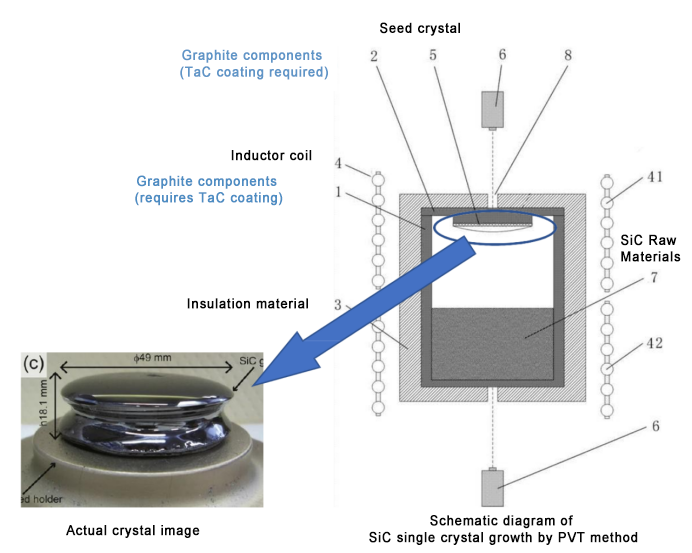

Uburyo bukoreshwa muburyo bwo gutegurasilicon karbidekristu imwe nuburyo bwa PVT (transport vapor transport). Ihame nugukora ibikoresho bibisi mukarere k'ubushyuhe bwo hejuru hamwe na kristu yimbuto mukarere gashushe cyane. Ibikoresho fatizo ku bushyuhe bwo hejuru birangirika kandi bigatanga umusaruro wa gaze ya gaz idafite icyiciro cyamazi. Ibintu bya gaze ya gaze bijyanwa muri kristu yimbuto munsi yubushyuhe bwa axial gradient, hanyuma nucleate hanyuma ikurira kuri kristu yimbuto kugirango ikore karibide ya silikoni imwe. Kugeza ubu, amasosiyete y’amahanga nka Cree, II-VI, SiCrystal, Dow hamwe n’amasosiyete yo mu gihugu nka Tianyue Advanced, Tianke Heda, na Century Golden Core bose bakoresha ubu buryo.

Hariho uburyo burenga 200 bwa kirisiti ya kariside ya silicon, kandi birasabwa kugenzura neza kugirango habeho ifaranga imwe isabwa (inzira nyamukuru ni 4H ya kristu). Dukurikije ibyifuzo bya Tianyue Advanced, umusaruro w’inkoni ya kristu y’isosiyete muri 2018-2020 na H1 2021 wari 41%, 38.57%, 50.73% na 49.90%, naho umusaruro w’ubutaka wari 72.61%, 75.15%, 70.44% na 75.47%. Umusaruro wuzuye kuri ubu ni 37.7% gusa. Dufashe uburyo nyamukuru bwa PVT nkurugero, umusaruro muke uterwa ahanini ningorane zikurikira mugutegura insimburangingo ya SiC:

1. , biragoye cyane kugenzura.

2. Umuvuduko wumusaruro gahoro: Iterambere ryibikoresho bya silikoni gakondo ni mm 300 mu isaha, ariko kariside ya kariside ya kariside imwe ishobora gukura mikoroni 400 mu isaha, ibyo bikaba bikubye inshuro 800 itandukaniro.

3. nkenerwa kugenzura neza ibipimo nkibipimo bya silicon-karubone, ubushyuhe bwikura ryikigereranyo, umuvuduko wubwiyongere bwa kirisiti, hamwe numuvuduko wumwuka. Bitabaye ibyo, polymorphic inclusion irashobora kubaho, bikavamo kristu itujuje ibyangombwa. Mu isanduku yumukara ya grafite ikomeye, ntibishoboka kwitegereza imiterere yo gukura kwa kristu mugihe nyacyo, kandi birasobanutse neza kugenzura ubushyuhe bwumuriro, guhuza ibikoresho, hamwe no gukusanya uburambe.

4. Mugihe ubunini bwa kristu bwiyongera, ingorane zayo zo gukura ziyongera cyane.

5. Muri rusange umusaruro muke: Umusaruro muke ugizwe ahanini nuburyo bubiri: (1) Umusaruro winkoni ya Crystal = icyiciro cya semiconductor-urwego rwoherejwe na kirisiti / / .

Mugutegura ubuziranenge bwiza kandi butanga umusaruro mwinshisilicon karbide substrates, intangiriro ikenera ibikoresho byiza byumuriro kugirango igenzure neza ubushyuhe bwumusaruro. Ubushuhe bwumuriro ibikoresho byingenzi bikoreshwa muri iki gihe ahanini ni ibice byubatswe byera cyane, bikoreshwa mu gushyushya no gushonga ifu ya karubone nifu ya silicon kandi bigakomeza gushyuha. Ibikoresho bya Graphite bifite ibimenyetso biranga imbaraga zidasanzwe hamwe na modulus yihariye, kurwanya ubushyuhe bwumuriro no kurwanya ruswa, ariko bifite ibibi byo kuba okiside byoroshye mubidukikije bwa ogisijeni yubushyuhe bwo hejuru, ntibirwanya ammoniya, hamwe no kurwanya nabi. Mubikorwa bya silicon karbide imwe ya kristu ikura kandisilicon karbide epitaxial waferumusaruro, biragoye kubahiriza abantu bagenda basabwa cyane kugirango bakoreshe ibikoresho bya grafite, bigabanya cyane iterambere ryabyo no kubishyira mubikorwa. Kubwibyo, ubushyuhe bwo hejuru cyane nka tantalum karbide byatangiye kugaragara.

2. IbirangaTantalum Carbide Coating

Ceramic ya TaC ifite aho ishonga igera kuri 3880 ℃, ubukana bwinshi (ubukana bwa Mohs 9-10), imiyoboro minini yubushyuhe (22W · m-1 · K - 1), imbaraga nini zunama (340-400MPa), hamwe no kwagura ubushyuhe buto coefficient (6.6 × 10−6K - 1), kandi yerekana ituze ryiza rya termo-chimique nibintu byiza bifatika. Ifite imiti ihuza imiti hamwe nubukanishi hamwe na grafite na C / C ibikoresho. Kubwibyo, TaC coating ikoreshwa cyane mukurinda ubushyuhe bwikirere, gukura kristu imwe, ibikoresho bya elegitoroniki, nibikoresho byubuvuzi.

Yashizwehografite ifite imiti irwanya ruswa kuruta grafite yambaye ubusa cyangwa grafite ya SiC ikozweho, irashobora gukoreshwa neza mubushyuhe bwo hejuru bwa 2600 °, kandi ntabwo ikora nibintu byinshi byuma. Nibintu byiza cyane mubisekuru bya gatatu igice kimwe cya kabiri cyogukwirakwiza hamwe na wafer etching scenarios. Irashobora kunoza cyane kugenzura ubushyuhe numwanda mubikorwa no guteguraubuziranenge bwa silicon karbide waferskandi bifitanye isanoepitaxial wafers. Irakwiriye cyane cyane gukura GaN cyangwa AlN kristu imwe hamwe nibikoresho bya MOCVD hamwe no gukura kristu imwe ya SiC hamwe nibikoresho bya PVT, kandi ubwiza bwa kristu imwe ikuze iratera imbere cyane.

III. Ibyiza bya Tantalum Carbide Ibikoresho Bitwikiriye

Ikoreshwa rya Tantalum Carbide TaC irashobora gukemura ikibazo cyinenge ya kirisiti kandi ikanoza ubwiza bwikura rya kristu. Nimwe mubyerekezo byingenzi bya tekinike yo "gukura byihuse, gukura cyane, no gukura birebire". Ubushakashatsi bwakozwe mu nganda bwerekanye kandi ko Tantalum Carbide Coated Graphite Crucible ishobora kugera ku bushyuhe bumwe, bityo igatanga uburyo bunoze bwo kugenzura imikurire ya SiC imwe rukumbi, bityo bikagabanya cyane amahirwe yo kubaho kwa polyikristaline ku nkombe za kirisiti ya SiC. Mubyongeyeho, Tantalum Carbide Graphite Coating ifite ibyiza bibiri byingenzi:

(I) Kugabanya Inenge za SiC

Kubijyanye no kugenzura inenge ya SiC imwe ya kristu, mubisanzwe hariho inzira eshatu zingenzi. Usibye kunonosora ibipimo byiterambere hamwe nibikoresho byujuje ubuziranenge (nka powder ya SiC), ukoresheje Tantalum Carbide Coated Graphite Crucible irashobora kandi kugera kubintu byiza bya kristu.

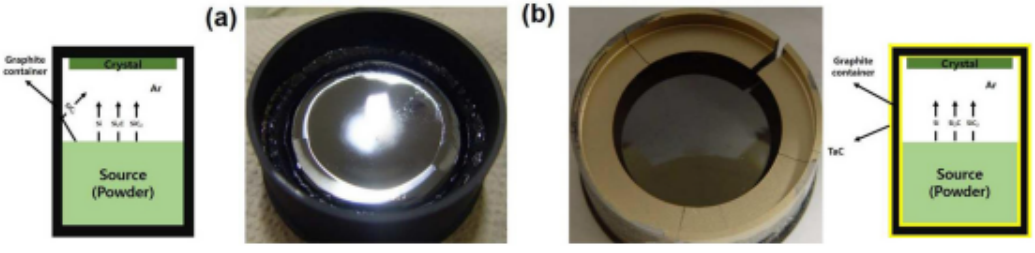

Igishushanyo mbonera cya grafite isanzwe iboneka (a) na TAC ikozweho ingirakamaro (b)

Nk’uko ubushakashatsi bwakozwe na kaminuza y’Uburayi bw’iburasirazuba muri Koreya bubitangaza, umwanda nyamukuru mu mikurire ya kirisiti ya SiC ni azote, kandi tantalum karbide yometse ku musaraba wa grafite irashobora kugabanya neza azote yinjizwamo na kirisiti ya SiC, bityo bikagabanya kubyara inenge nka micropipes no kunoza kristu ubuziranenge. Ubushakashatsi bwerekanye ko mu bihe bimwe, ubwikorezi bwa waC ya wafers ikura mu musaraba usanzwe wa grafite na TAC ikozweho ingero zingana na 4.5 × 1017 / cm na 7,6 × 1015 / cm.

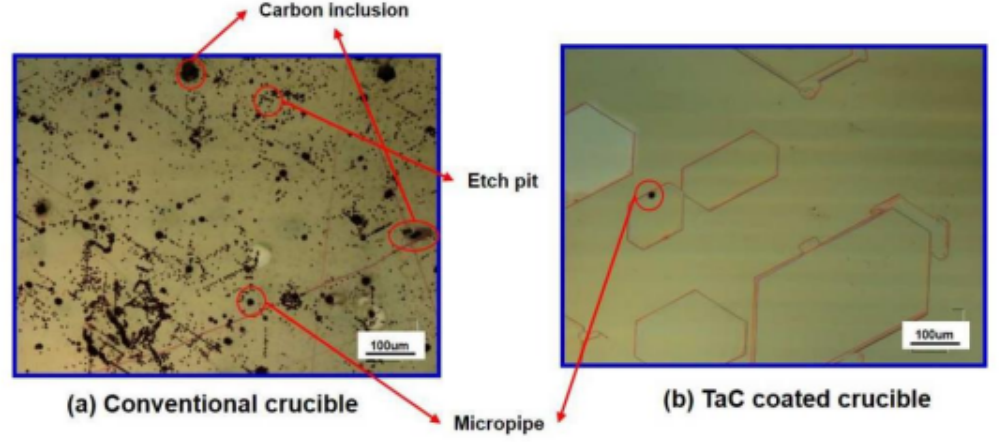

Kugereranya inenge ziri muri kristu imwe ya SiC ikura mu musaraba usanzwe wa grafite (a) na TAC utwikiriwe (b)

(II) Gutezimbere ubuzima bwimikorere ya grafite

Kugeza ubu, ibiciro bya kristu ya SiC byakomeje kuba hejuru, muri byo ikiguzi cyibikoresho bya grafite bingana na 30%. Urufunguzo rwo kugabanya ikiguzi cya grafite ni ukongera ubuzima bwa serivisi. Dukurikije imibare yaturutse mu itsinda ry’ubushakashatsi bw’Abongereza, tantalum karbide yatwikiriye ishobora kongera igihe cya serivisi y’ibigize grafite 30-50%. Ukurikije iyi mibare, gusa gusimbuza tantalum karbide isize grafite bishobora kugabanya igiciro cya kristu ya SiC 9% -15%.

4. Tantalum karbide yo gutwikira

Uburyo bwo gutegura igifuniko cya TaC burashobora kugabanywamo ibyiciro bitatu: uburyo bukomeye bwicyiciro, uburyo bwicyiciro cyamazi nuburyo bwa gaz gaz. Uburyo bukomeye bwicyiciro burimo uburyo bwo kugabanya nuburyo bwimiti; uburyo bwicyiciro cyamazi kirimo uburyo bwumunyu ushongeshejwe, uburyo bwa sol-gel (Sol-Gel), uburyo bwo gucumura, uburyo bwo gutera plasma; uburyo bwa gaz gaz burimo imyuka ya chimique (CVD), kwinjiza imyuka ya chimique (CVI) hamwe no kubika imyuka yumubiri (PVD). Uburyo butandukanye bufite ibyiza byabwo nibibi. Muri byo, CVD nuburyo bukuze kandi bukoreshwa cyane mugutegura ibishishwa bya TaC. Hamwe nogukomeza kunoza imikorere, hateguwe uburyo bushya nkubushyuhe bwumuriro wumuyaga ushushe hamwe na ion beam ifasha imyuka ya chimique.

TaC itwikiriye ibikoresho byahinduwe na karubone ahanini birimo grafite, fibre karubone, hamwe nibikoresho bya karubone. Uburyo bwo gutegura ibishishwa bya TaC kuri grafite harimo gutera plasma, CVD, gucumura neza, nibindi.

Ibyiza byuburyo bwa CVD: Uburyo bwa CVD mugutegura ibishishwa bya TaC bishingiye kuri tantalum halide (TaX5) nkisoko ya tantalum na hydrocarubone (CnHm) nkisoko ya karubone. Mubihe bimwe na bimwe, babora muri Ta na C, hanyuma bakitwara hagati yabo kugirango babone TaC. Uburyo bwa CVD burashobora gukorwa mubushyuhe buke, bushobora kwirinda inenge no kugabanya imiterere yubukanishi buterwa no gutegura ubushyuhe bwinshi cyangwa kuvura impuzu kurwego runaka. Ibigize nuburyo byububiko birashobora kugenzurwa, kandi bifite ibyiza byo kwera kwinshi, ubucucike bwinshi, nubunini bumwe. Icy'ingenzi cyane, imiterere nuburyo bwa TaC bitwikiriye byateguwe na CVD birashobora gushushanywa kandi bikagenzurwa byoroshye. Nuburyo bukuze kandi bukoreshwa cyane mugutegura ubuziranenge bwa TaC.

Ibyingenzi bigira ingaruka mubikorwa birimo:

A. Igipimo cya gazi (isoko ya tantalum, gaze ya hydrocarubone nkisoko ya karubone, gaze yabatwara, gaze ya dilution Ar2, kugabanya gaze H2): Ihinduka ryumuvuduko wa gazi rifite ingaruka zikomeye kumurima wubushyuhe, umurima wumuvuduko, numurima wa gazi muri urugereko rwa reaction, bivamo impinduka mubigize, imiterere, n'imikorere ya coating. Kongera umuvuduko wa Ar bizadindiza umuvuduko wikura ryikigero kandi bigabanye ingano yingano, mugihe umubyimba mwinshi wa TaCl5, H2, na C3H6 ugira ingaruka kumiterere. Ikigereranyo cya mara ya H2 na TaCl5 ni (15-20): 1, birakwiriye. Ikigereranyo cya molar ya TaCl5 na C3H6 ni mubyukuri hafi ya 3: 1. TaCl5 ikabije cyangwa C3H6 bizatera ishingwa rya Ta2C cyangwa karubone yubusa, bigira ingaruka kumiterere ya wafer.

B. Ubushyuhe bwo kubitsa: Ubushyuhe bwo hejuru bwarushijeho kwiyongera, niko umuvuduko wo kubitsa byihuta, ingano nini nini, hamwe nigitambaro gikabije. Mubyongeyeho, ubushyuhe n'umuvuduko wo kwangirika kwa hydrocarubone muri C na TaCl5 kubora muri Ta biratandukanye, kandi Ta na C birashoboka cyane gukora Ta2C. Ubushyuhe bugira uruhare runini kuri TaC gutwikira ibikoresho bya karubone byahinduwe. Mugihe ubushyuhe bwokwiyongera bwiyongera, igipimo cyo kubitsa kiriyongera, ingano yingingo iriyongera, kandi imiterere yibice ihinduka kuva muri serefegitura ikagera kuri polyhedrale. Mubyongeyeho, uko ubushyuhe bwo hejuru bwiyongera, niko kwangirika kwinshi kwa TaCl5, C ntizigabanuka kubuntu, niko guhangayikishwa cyane no gutwikirwa, kandi ibice bizabyara byoroshye. Nyamara, ubushyuhe buke bwo kugabanuka buzatuma habaho kugabanuka neza, igihe kinini cyo kubitsa, hamwe nigiciro kinini cyibikoresho fatizo.

C. Umuvuduko wo kubitsa: Umuvuduko wo kubitsa ufitanye isano rya hafi ningufu zubusa zubutaka bwibintu kandi bizagira ingaruka kumwanya wo gutura gaze mubyumba byabigizemo uruhare, bityo bikagira ingaruka kumuvuduko wa nucleation nubunini bwa coating. Mugihe umuvuduko wo kubitsa wiyongera, igihe cyo gutura gaze kiba kirekire, reaction zifite igihe kinini cyo gukora nucleation reaction, igipimo cyibisubizo cyiyongera, ibice biba binini, kandi igifuniko kikaba kinini; muburyo bunyuranye, uko umuvuduko wo kugabanuka ugabanuka, igihe cyo gutura gazi itwara igihe gito, igipimo cyibisubizo kigenda gahoro, ibice biba bito, kandi igipfundikizo kikaba gito, ariko igitutu cyo kubitsa ntikigira ingaruka nke kumiterere ya kristu no muburyo bwa coating.

V. Iterambere ryiterambere rya tantalum karbide

Coefficente yo kwagura ubushyuhe bwa TaC (6.6 × 10−6K - 1) iratandukanye cyane nibikoresho bishingiye kuri karubone nka grafite, fibre karubone, hamwe nibikoresho bya C / C, bigatuma ibice bya TaC byicyiciro kimwe bikunda gucika kandi kugwa. Mu rwego rwo kurushaho kunoza uburyo bwo gukuraho no gukwirakwiza okiside, ubushyuhe bwo hejuru bw’ubushyuhe bwo hejuru, hamwe n’ubushyuhe bwo mu rwego rwo hejuru bwangirika bw’imiti ya TaC, abashakashatsi bakoze ubushakashatsi kuri sisitemu yo gutwikira nka sisitemu yo gutwikira, uburyo bukomeye bwo gukemura ibibazo, hamwe na gradient. sisitemu yo gutwikira.

Sisitemu yo guteranya ibintu ni ugufunga ibice byumwenda umwe. Mubisanzwe, ibindi bitwikiro byinjizwa mubuso cyangwa imbere imbere ya TaC kugirango habeho sisitemu yo gutwikira; igisubizo gihamye gishimangira sisitemu yo gutwikira HfC, ZrC, nibindi bifite imiterere ya cubic-centre ya cubic imiterere ya TaC, kandi karbide zombi zirashobora gushonga bitagira ingano murindi kugirango habeho igisubizo gikomeye. Igipfundikizo cya Hf (Ta) C ntigishobora kumeneka kandi gifatanye neza nibikoresho bya C / C. Igifuniko gifite imikorere myiza yo kurwanya ablation; sisitemu yo gutondekanya icyiciro cya gradient coating yerekana icyerekezo cyibice byerekeranye nicyerekezo cyacyo. Imiterere irashobora kugabanya imihangayiko yimbere, kunoza kudahuza coefficient zo kwagura ubushyuhe, no kwirinda gucika.

(II) Ibikoresho bya Tantalum karbide

Dukurikije imibare n’ibiteganijwe kuri QYR (Hengzhou Bozhi), kugurisha isoko rya tantalum karbide ku isi mu 2021 byageze kuri miliyoni 1.5986 z’amadolari y’Amerika (ukuyemo Cree yikorera wenyine kandi yihaye ibikoresho bya tantalum karbide yifashisha ibikoresho), kandi biracyari mu ntangiriro. ibyiciro byo guteza imbere inganda.

1.

2. Inzira ya TaC: Buri tray irashobora gutwara wafer 3, buri tray irashobora gukoreshwa ukwezi 1, kandi tray 1 ikoreshwa kuri buri waferi 100. Miliyoni 3 za wafer zisaba 30.000 TaC tray, buri tray ni ibice 20.000, kandi hakenewe miliyoni 600 buri mwaka.

3. Ibindi bintu byo kugabanya karubone. Nka feri yubushyuhe bwo hejuru, CVD nozzle, imiyoboro yitanura, nibindi, hafi miliyoni 100.

Igihe cyo kohereza: Jul-02-2024