Ubucuruzi bwacu bwibanze ku ngamba zo kwamamaza. Ibyishimo byabakiriya niyamamaza ryiza cyane. Turatanga kandi isosiyete ya OEM kubushinwa Bwumwuga Bwubushyuhe Bwinshi bwo Kubungabunga Ingufu Zibungabunga Silicon Carbide Graphite Crucible kumuringa Aluminium Bronze Umuringa Zink Tin Casting, Nkuko twakomeje gutera imbere, dukomeje guhanga amaso ibintu bigenda byiyongera kandi tunonosora ibintu serivisi zacu.

Ubucuruzi bwacu bwibanze ku ngamba zo kwamamaza. Ibyishimo byabakiriya niyamamaza ryiza cyane. Turatanga kandi sosiyete ya OEM kuriUbushinwa Mold na Graphite, Kubera ubwitange bwacu, ibicuruzwa byacu birazwi kwisi yose kandi ibicuruzwa byohereza hanze bikomeza kwiyongera buri mwaka. Tuzakomeza guharanira kuba indashyikirwa dutanga ibicuruzwa byiza byo hejuru birenze ibyo abakiriya bacu bategereje.

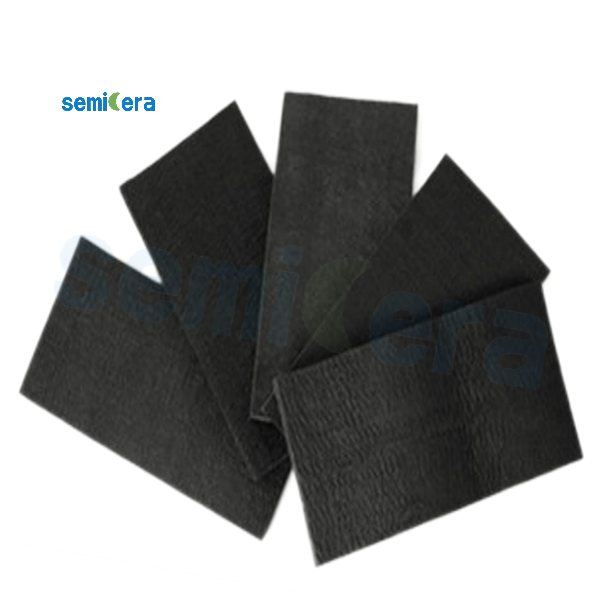

Graphite ikomeye ikoreshwa cyane cyane mu gushonga umuringa, umuringa, zahabu, ifeza, zinc na gurş, hamwe nibindi byuma bidafite fer hamwe na alloys.

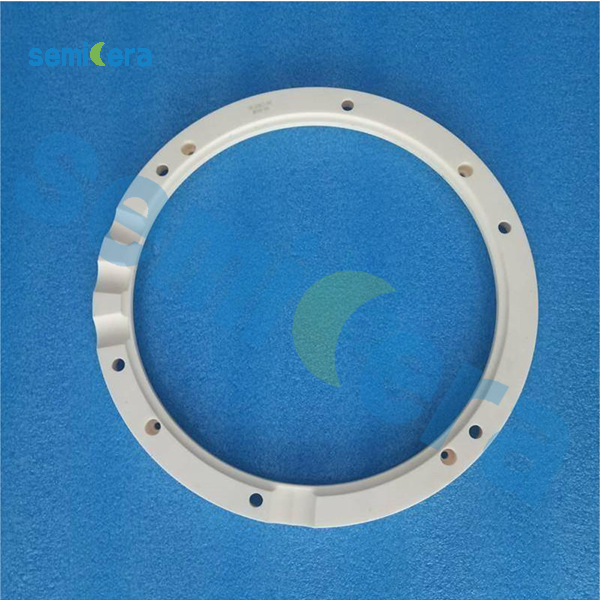

Igishushanyo mbonera cyacu gitunganijwe neza hamwe na isitatike ikanda cyane ya grafite, ifite ubushyuhe bwiza nubushyuhe bwo hejuru. Muburyo bwo gukoresha ubushyuhe bwo hejuru, coefficient yo kwagura ubushyuhe ni nto, kandi ifite imbaraga zo kurwanya ubushyuhe bukabije no gukonja gukabije. Ifite ruswa irwanya aside na alkaline yumuti hamwe nubushakashatsi bwiza bwimiti. Moderi yihariye irashobora guhindurwa hamwe nigishushanyo nicyitegererezo, kandi ibikoresho ni grafite yo murugo hamwe na grafite yatumijwe hanze kugirango ihuze ibyifuzo bitandukanye byabakiriya.

Ibikoresho fatizo byingenzi bya grafite ni grafite, karubide ya silicon, silika, ibumba ryangiritse, ikibuga, nigituba, nibindi.

> Igishushanyo Cyiza cya Graphite Crucible

> Igishushanyo cya Isostatike

> Silicon Carbide Graphite Crucible

> Carbide ya Silicon

> Ibumba ryibumba ryibumba

> Quarts Crucible

Ibiranga:

1. Igihe kirekire cyo gukora

2. Amashanyarazi menshi

3. Ibikoresho-bishya

4. Kurwanya ruswa

5. Kurwanya okiside

6. Imbaraga nyinshi

7. Imikorere myinshi

| Tekiniki ya Tekiniki Yibikoresho | |||

| Ironderero | Igice | Agaciro gasanzwe | Agaciro k'ikizamini |

| Kurwanya Ubushyuhe | ℃ | 1650 ℃ | 1800 ℃ |

| Ibigize imiti | C | 35 ~ 45 | 45 |

| SiC | 15 ~ 25 | 25 | |

| AL2O3 | 10 ~ 20 | 25 | |

| SiO2 | 20 ~ 25 | 5 | |

| Ikigaragara | % | ≤30% | ≤28% |

| Imbaraga zo guhonyora | Mpa | .58.5MPa | .58.5MPa |

| Ubucucike bwinshi | g / cm3 | ≥1.75 | 1.78 |

| Carbide ya silicon yacu ikomeye ni isostatike ikora, ishobora gukoresha inshuro 23 mu itanura, mugihe izindi zishobora gukoresha inshuro 12 gusa | |||

Ubucuruzi bwacu bwibanze ku ngamba zo kwamamaza. Ibyishimo byabakiriya niyamamaza ryiza cyane. Turatanga kandi isosiyete ya OEM kubushinwa Bwumwuga Bwubushyuhe Bwinshi bwo Kubungabunga Ingufu Zibungabunga Silicon Carbide Graphite Crucible kumuringa Aluminium Bronze Umuringa Zink Tin Casting, Nkuko twakomeje gutera imbere, dukomeje guhanga amaso ibintu bigenda byiyongera kandi tunonosora ibintu serivisi zacu.

Abashinwa b'umwugaUbushinwa Mold na Graphite, Kubera ubwitange bwacu, ibicuruzwa byacu birazwi kwisi yose kandi ibicuruzwa byohereza hanze bikomeza kwiyongera buri mwaka. Tuzakomeza guharanira kuba indashyikirwa dutanga ibicuruzwa byiza byo hejuru birenze ibyo abakiriya bacu bategereje.

-

Abacuruzi beza benshi bagurisha Ubushinwa Bwiza Bwiza ...

-

OEM Uruganda rukora Ubushinwa Uruganda Igiciro Igiciro ...

-

Igiciro cyo hasi Ceramic Refractory Sisic Rbsic Sil ...

-

Ibicuruzwa byinshi bya OEM Uruganda Igiciro C Inganda C ...

-

Ubwiza bwiza 50% ubwoya 50% Urushinge rworoshye rwa sintetike ...

-

Ubwiza Bwiza Silicon Carbide Yubusa Crucibl ...