Bikaba bifite imyifatire myiza kandi itera imbere kubakiriya bashimishwa, uruganda rwacu ruhora rutezimbere ibintu byacu byiza kugirango duhaze ibyifuzo byabakiriya kandi bikomeza kwibanda kumutekano, kwiringirwa, kubidukikije, no guhanga udushya dushyushye dushyushye Sic Kiln Furnace Silicon Carbide Ceramic Arc Zahabu Gushonga Crucible, Twari tuzi neza ubuziranenge, kandi dufite icyemezo ISO / TS16949: 2009. Twiyemeje kuguha ibicuruzwa byiza nibisubizo hamwe nigiciro cyemewe.

Bikaba bifite imyumvire myiza kandi igenda itera imbere gushimisha abakiriya, uruganda rwacu ruhora rutezimbere ibintu byacu byiza kugirango duhaze ibyifuzo byabakiriya kandi bikomeza kwibanda kumutekano, kwiringirwa, kubidukikije, no guhanga udushya.Ubushinwa Ssic Isahani hamwe nimpapuro za Ssic, Noneho tumaze kumenyekana cyane mubakiriya bakwirakwijwe kwisi yose. Baratwizeye kandi burigihe batanga amategeko asubiramo. Byongeye kandi, twavuze haruguru ni bimwe mubintu byingenzi byagize uruhare runini mu mikurire yacu ikomeye muri uru rwego.

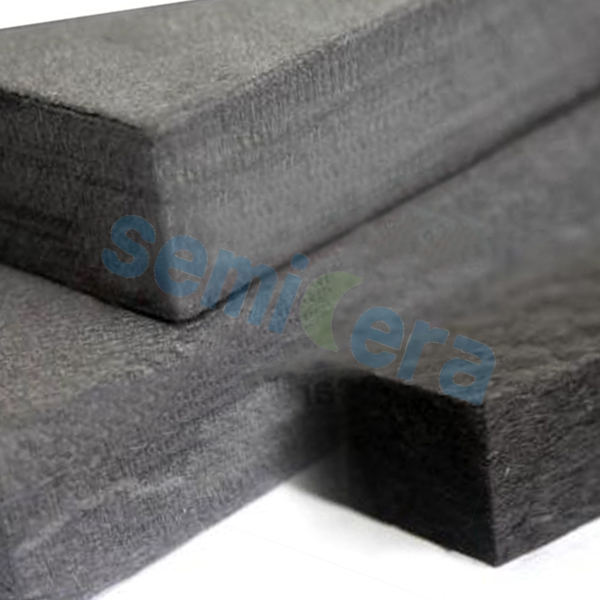

Graphite ikomeye ikoreshwa cyane cyane mu gushonga umuringa, umuringa, zahabu, ifeza, zinc na gurş, hamwe nibindi byuma bidafite fer hamwe na alloys.

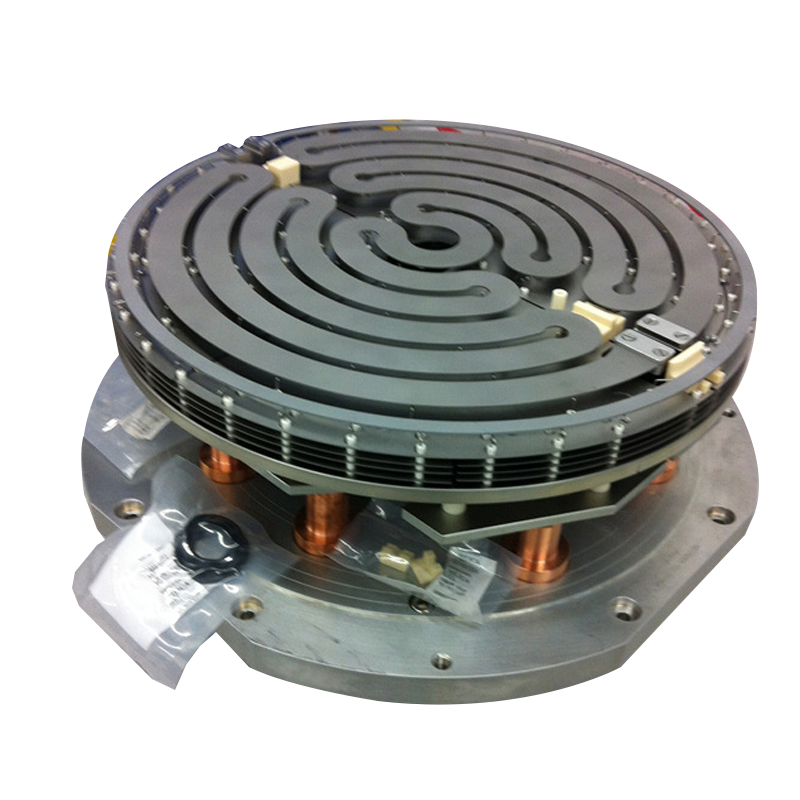

Igishushanyo mbonera cyacu gitunganijwe neza hamwe na isitatike ikanda cyane ya grafite, ifite ubushyuhe bwiza nubushyuhe bwo hejuru. Muburyo bwo gukoresha ubushyuhe bwo hejuru, coefficient yo kwagura ubushyuhe ni nto, kandi ifite imbaraga zo kurwanya ubushyuhe bukabije no gukonja gukabije. Ifite ruswa irwanya aside na alkaline yumuti hamwe nubushakashatsi bwiza bwimiti. Moderi yihariye irashobora guhindurwa hamwe nigishushanyo nicyitegererezo, kandi ibikoresho ni grafite yo murugo hamwe na grafite yatumijwe hanze kugirango ihuze ibyifuzo bitandukanye byabakiriya.

Ibikoresho fatizo byingenzi bya grafite ni grafite, karubide ya silicon, silika, ibumba ryangiritse, ikibuga, nigituba, nibindi.

> Igishushanyo Cyiza cya Graphite Crucible

> Igishushanyo cya Isostatike

> Silicon Carbide Graphite Crucible

> Carbide ya Silicon

> Ibumba ryibumba ryibumba

> Quarts Crucible

Ibiranga:

1. Igihe kirekire cyo gukora

2. Amashanyarazi menshi

3. Ibikoresho-bishya

4. Kurwanya ruswa

5. Kurwanya okiside

6. Imbaraga nyinshi

7. Imikorere myinshi

| Tekiniki ya Tekiniki Yibikoresho | |||

| Ironderero | Igice | Agaciro gasanzwe | Agaciro k'ikizamini |

| Kurwanya Ubushyuhe | ℃ | 1650 ℃ | 1800 ℃ |

| Ibigize imiti | C | 35 ~ 45 | 45 |

| SiC | 15 ~ 25 | 25 | |

| AL2O3 | 10 ~ 20 | 25 | |

| SiO2 | 20 ~ 25 | 5 | |

| Ikigaragara | % | ≤30% | ≤28% |

| Imbaraga zo guhonyora | Mpa | .58.5MPa | .58.5MPa |

| Ubucucike bwinshi | g / cm3 | ≥1.75 | 1.78 |

| Carbide ya silicon yacu ikomeye ni isostatike ikora, ishobora gukoresha inshuro 23 mu itanura, mugihe izindi zishobora gukoresha inshuro 12 gusa | |||

Bikaba bifite imyifatire myiza kandi itera imbere kubakiriya bashimishwa, uruganda rwacu ruhora rutezimbere ibintu byacu byiza kugirango duhaze ibyifuzo byabakiriya kandi bikomeza kwibanda kumutekano, kwiringirwa, kubidukikije, no guhanga udushya dushyushye dushyushye Sic Kiln Furnace Silicon Carbide Ceramic Arc Zahabu Gushonga Crucible, Twari tuzi neza ubuziranenge, kandi dufite icyemezo ISO / TS16949: 2009. Twiyemeje kuguha ibicuruzwa byiza nibisubizo hamwe nigiciro cyemewe.

Kugurisha bishyushyeUbushinwa Ssic Isahani hamwe nimpapuro za Ssic, Noneho tumaze kumenyekana cyane mubakiriya bakwirakwijwe kwisi yose. Baratwizeye kandi burigihe batanga amategeko asubiramo. Byongeye kandi, twavuze haruguru ni bimwe mubintu byingenzi byagize uruhare runini mu mikurire yacu ikomeye muri uru rwego.

-

Igiciro Cyinshi Ubushinwa Ubushyuhe Kurwanya Carbon Ro ...

-

Igiciro Cyinshi Ubushinwa Bukuru bwa Graphite Ifunga ...

-

Uruganda Ahantu ho Kurwanya Ubushyuhe / Roller Th ...

-

Igishushanyo cyihariye cyo gutanga uruganda rutari Asibesitosi ...

-

Ihinguriro rya Sic Heating Element; Sic Ashyushye R ...

-

OEM Yashizeho Isuri Nziza Kurwanya Magnesiu ...