Quartz: Ikintu Cyingenzi muri Electronics Zigezweho

Intangiriro kubikoresho bya Quartz

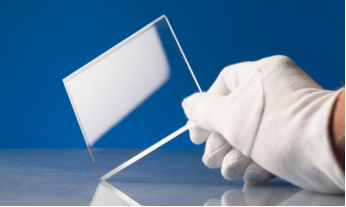

Quartz (SiO₂) irashobora kumera nkikirahure ukireba, ariko imiterere yihariye iragitandukanya. Bitandukanye nikirahure gisanzwe, kigizwe nibice byinshi (nkumusenyi wa quartz, borax, barium karubone, hekeste, feldspar, na soda), quartz igizwe na SiO₂ gusa. Ibi birayiha imiterere yoroshye y'urusobe rwakozwe na tetrahedral ibice bya silicon dioxyde.

Akamaro ka Quartz-Yera

Quartz-isukuye cyane, bakunze kwitwa "ikamba rya zahabu" ry'ibikoresho by'ibirahure, itanga ibintu bidasanzwe kubera umwanda muke muto. Ibi bikoresho bidasanzwe nibyingenzi mubikorwa bitandukanye bya semiconductor, kwirata ibyiza nka:

1.

2.

3. Ubushyuhe bwumuriro: Quartz ifite isuku nyinshi ifite coeffisiyeti yo kwagura ubushyuhe buke cyane, ituma ishobora kwihanganira ihinduka ryubushyuhe bwihuse itavunitse.

4. Ibyiza bisobanutse: Ibi bikoresho bikomeza kwanduza cyane mu buryo bwagutse, hamwe n’umucyo ugaragara urenga 93% naho itumanaho rya ultraviolet rikagera hejuru ya 80%.

5. Gukwirakwiza amashanyarazi: Quartz ifite isuku nyinshi itanga imbaraga zidasanzwe zo kurwanya amashanyarazi, bigatuma ikora neza cyane nubwo haba hari ubushyuhe bwinshi.

Porogaramu mu nganda za Semiconductor

Bitewe niyi miterere idasanzwe yumubiri nubumashini, quartz-isukuye cyane ikoreshwa cyane mubikoresho bya elegitoroniki bigezweho, itumanaho, ninganda ziciriritse. Ubwiyongere bukenewe kuri wafer ya silicon bwongereye cyane ibikenerwa bya quartz, cyane cyane mubikorwa bya chip.

Ibyingenzi Byingenzi bya Quartz mubikorwa bya Semiconductor:

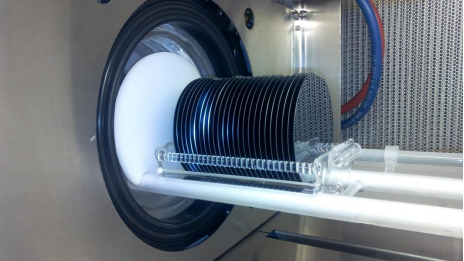

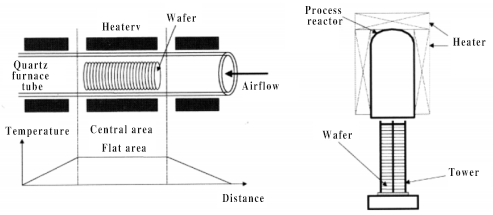

1. Ibikoresho Byinshi-Ubushyuhe:

· Ibikoresho bya Quartz Furnace:Ibyingenzi mubikorwa nka diffuzione, okiside, hamwe na annealing, iyi miyoboro ituma ubushyuhe bwo hejuru butajegajega kandi bukora neza mugihe cyo guhimba semiconductor.

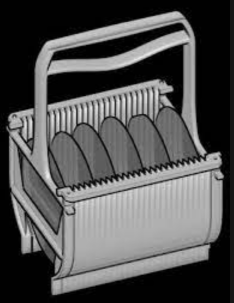

Ubwato bwa Quartz:Ikoreshwa mugutwara no gutunganya wafer ya silicon, ubwato bwa quartz bworoshya ibyiciro mubikorwa byo gukwirakwiza.

2. Ibikoresho byo hasi-Ubushyuhe:

Impeta ya Quartz:Ibyingenzi muburyo bwo gutobora, impeta ya quartz irinda kwanduza no kwemeza gukora neza mugihe cya lithographie no gushushanya.

· Quartz Isukura Ibitebo na Tank:Ibi bice nibyingenzi mugusukura wafer ya silicon. Bagomba kurwanya aside na alkali mugihe bagabanije aho bahurira kugirango bongere neza isuku.

Umwanzuro

Mugihe ibice bya quartz bishobora kugaragara nkibikoreshwa byoroheje mubikorwa byo gukora igice cya kabiri, bigira uruhare runini mukwemeza ubwiza nubwizerwe bwibikoresho bya semiconductor. Nk’uko Techcet ibivuga, ibikoresho by'ibirahure bya quartz bifite isuku bigera kuri 90% by'umusaruro ngarukamwaka ku isi mu bucuruzi bw'ikoranabuhanga.

Muri Semicera, twiyemeje guteza imbere inganda za semiconductor dutanga ibikoresho bya quartz ikora neza. Nkuko imisumari ari ngombwa kugirango uburinganire bwimiterere, niko na quartz yo gukora semiconductor.

2. Ibikoresho byo hasi-Ubushyuhe:

·Impeta ya Quartz: Byibanze mubikorwa byo gutobora, impeta ya quartz irinda kwanduza no kwemeza gukora neza mugihe cya lithographie no gushushanya.

·Quartz Isukura Ibitebo na Tank: Ibi bice nibyingenzi mugusukura wafer ya silicon. Bagomba kurwanya aside na alkali mugihe bagabanije aho bahurira kugirango bongere neza isuku.

Umwanzuro

Mugihe ibice bya quartz bishobora kugaragara nkibikoreshwa byoroheje mubikorwa byo gukora igice cya kabiri, bigira uruhare runini mukwemeza ubwiza nubwizerwe bwibikoresho bya semiconductor. Nk’uko Techcet ibivuga, ibikoresho by'ibirahure bya quartz bifite isuku bigera kuri 90% by'umusaruro ngarukamwaka ku isi mu bucuruzi bw'ikoranabuhanga.

Muri Semicera, twiyemeje guteza imbere inganda za semiconductor dutanga ibikoresho bya quartz ikora neza. Nkuko imisumari ari ngombwa kugirango uburinganire bwimiterere, niko na quartz yo gukora semiconductor.